Background[edit | edit source]

Undergraduate civil engineering student at Western University. Designer, builder, and academic writer of DIY open-source wooden solar racking systems.

Interested in structural design, analysis, material engineering, and structural integration with PV systems.

Proficient in AutoCAD, SAP 2000, and Microsoft Office.

Research[edit | edit source]

Currently researching Open Source Appropriate Technology under the supervision of Dr. Joshua Pearce for FAST.

Developing a series of sustainable open source wood-based PV racking articles, providing DIY instructions on how to design and build an outdoor wooden PV rack in correspondence with Canadian building codes and specifications. Thus far, work has been done in fixed tilt, variable tilt, vertical, and EV Carport PV racking systems that follow these objectives. Moreover, developing a series of low-cost DIY metal racking systems, all with materials readily available at local hardware stores.

Publications[edit | edit source]

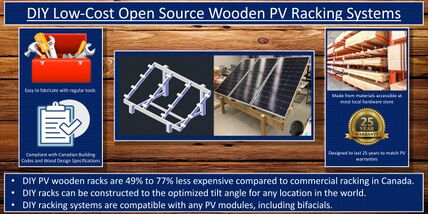

DIY Low-Cost Open Source Wooden PV Racking Systems[edit | edit source]

This do-it-yourself PV rack design is provided and analyzed here for six criteria:(1) made from locally-accessible renewable materials, (2) 25-year lifetime to match PV warranties, (3) able to be fabricated by average consumers, (4) able to meet Canadian structural building codes, (5) low cost and (6) that it is shared using an open-source license. Economic analysis of the bill of materials showed the racking system ranges from 49% to 77% less expensive compared to commercial proprietary racking in Canada.

Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Impacts of Location on Designs and Economics of DIY Low-Cost Fixed-Tilt Open Source Wood Solar Photovoltaic Racking. Designs 2022, 6, 41, doi:10.3390/designs6030041.

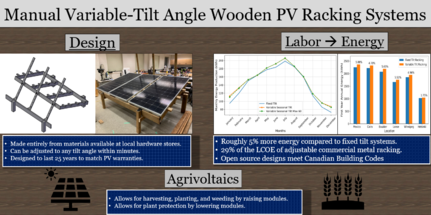

Variable-Tilt Angle DIY Wood-Based Solar Photovoltaic Racking Systems[edit | edit source]

To determine if wood racking provides enough savings to enable labor to be exchanged profitably for higher solar electric output, this article develops a novel variable tilt angle open-source wood-based do-it-yourself (DIY) PV rack that can be built and adjusted at exceptionally low costs. A detailed levelized cost of electricity (LCOE) production analysis is performed after the optimal monthly tilt angles are determined for a range of latitudes. The results show the racking systems with an optimal variable seasonal tilt angle have the best lifetime energy production, with 5.2% more energy generated compared to the fixed-tilt system (or 4.8% more energy, if limited to a maximum tilt angle of 60°). Both fixed and variable wooden racking systems show similar LCOE, which is only 29% of the LCOE of commercial metal racking. The results of this study indicate that the novel variable tilt rack, whether used as a small-scale DIY project or scaled up to fulfill larger energy demands, provides both the lowest cost option even when modest labor costs are included and also may provide specific advantages for applications such as agrivoltaics.

Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Open-Source Design and Economics of Manual Variable-Tilt Angle DIY Wood-Based Solar Photovoltaic Racking System. Designs 2022, 6, 54. https://doi.org/10.3390/designs6030054

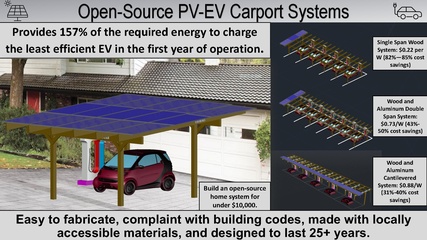

Open Source PV-EV Carport Systems[edit | edit source]

Solar powering the increasing fleet of electrical vehicles (EV) demands more surface area than may be available for photovoltaic (PV)-powered buildings. Parking lot solar canopies can provide the needed area to charge EVs but are substantially costlier than roof- or ground-mounted PV systems. To provide a low-cost PV parking lot canopy to supply EV charging, in this study, we provide a full mechanical and economic analysis of three novel PV canopy systems: (1) an exclusively wood, single-parking-spot spanning system, (2) a wood and aluminum double-parking-spot spanning system, and (3) a wood and aluminum cantilevered system for curbside parking. All three systems can be scaled to any amount of EV parking spots. The complete designs and bill of materials (BOM) of the canopies are provided, along with basic instructions, and are released with an open-source license that will enable anyone to fabricate them. Analysis results indicate that single-span systems provide cost savings of 82–85%, double-span systems save 43–50%, and cantilevered systems save 31–40%. In the first year of operation, PV canopies can provide 157% of the energy needed to charge the least efficient EV currently on the market if it is driven the average driving distance in London, ON, Canada.

Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Open-Source Photovoltaic—Electrical Vehicle Carport Designs. Technologies 2022, 10, 114. https://doi.org/10.3390/technologies10060114

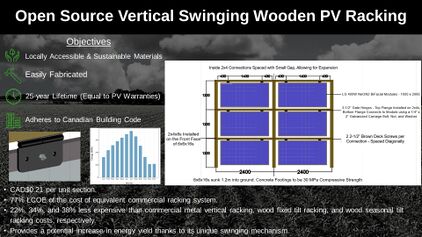

Open-Source Vertical Swinging Wood-Based Solar Photovoltaic Racking Systems[edit | edit source]

Vertical bifacial solar photovoltaic (PV) racking systems offer the opportunity for large-scale agrivoltaics to be employed at farms producing field crops with conventional farming equipment. Unfortunately, commercial proprietary vertical racks cost more than all types of conventional PV farm racking solutions. To overcome these cost barriers, this study reports on the development of a new wood-based PV racking design. The open-source design consists of a hinge mechanism, which reduces mechanical loading and enables wood to be used as the main structural material, and is the first of its kind. This open-source vertical wood-based PV rack is (i) constructed from locally accessible (domestic) renewable and sustainable materials, (ii) able to be made with hand tools by the average farmer on site, (iii) possesses a 25-year lifetime to match PV warranties, and (iv) is structurally sound, following Canadian building codes to weather high wind speeds and heavy snow loads. The results showed that the capital cost of the racking system is less expensive than the commercial equivalent and all of the previous wood-based rack designs, at a single unit retail cost of CAD 0.21. The racking LCOE is 77% of the cost of an equivalent commercial racking system using retail small-scale component costs, and is 22%, 34%, and 38% less expensive than commercial metal vertical racking, wood fixed tilt racking, and wood seasonal tilt racking costs, respectively. Overall, wooden vertical swinging PV racking provides users with a low-cost, highly available alternative to conventional metal vertical racking, along with a potential increase in energy yield in high wind areas thanks to its unique swinging mechanism.

Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Open-Source Design and Economics of Manual Variable-Tilt Angle DIY Wood-Based Solar Photovoltaic Racking System. Designs 2022, 6, 54. https://doi.org/10.3390/designs6030054 academia open access

Geographical Dependence of Open Hardware Optimization: Case Study of Solar Photovoltaic Racking[edit | edit source]

Open-source technological development is well-known for rapid innovation and providing opportunities to reduce costs and thus increase accessibility for a wide range of products. This is done through distributed manufacturing, in which products are produced close to end users. There is anecdotal evidence that these opportunities are heavily geographically dependent, with some locations unable to acquire components to build open hardware at accessible prices because of trade restrictions, tariffs, taxes, or market availability. Supply chain disruptions during the COVID-19 pandemic exacerbated this and forced designers to pivot towards a la carte-style design frameworks for critical system components. To further develop this phenomenon, a case study of free and open-source solar photovoltaic (PV) racking systems is provided. Two similar open-source designs made from different materials are compared in terms of capital costs for their detailed bill of materials throughout ten locations in North, Central and South America. The differences in economic optimization showed that the costs of wood-based racks were superior in North America and in some South American countries, while metal was less costly in Central and South America. The results make it clear that open hardware designs would be best to allow for local optimization based on material availability in all designs.

Rana, S.; Vandewetering, N.; Powell, J.; Ariza, J.Á.; Pearce, J.M. Geographical Dependence of Open Hardware Optimization: Case Study of Solar Photovoltaic Racking. Technologies 2023, 11, 62. https://doi.org/10.3390/technologies11020062

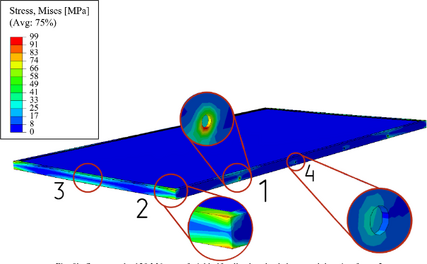

Mechanical and economic analysis of conventional aluminum photovoltaic module frames, frames with side holes, and open-source downward-fastened frames for non-traditional racking[edit | edit source]

Using bolts through the back of a solar photovoltaic (PV) module frames to attach them to racking is time consuming and awkward, so commercial PV installations use clamping technologies on the front. Conventional and proprietary clamps are costly and demand access to supply chains for uncommon mechanical components that limits deployment velocity. To overcome these challenges, this study presents new open-source downward-fastened and side-fastened aluminum (Al) framing designs, which are easy to install and compatible with metal and wood racks. The proposed parametric open source designs are analyzed through finite element methods (FEM) simulations and economic analysis is performed to compare to conventional PV frame at both the module and system levels. The FEM results showed all the frames have acceptable mechanical reliability and stability to pass IEC 61215 standards. The results show the new frame (with bottom width of 29 mm and thickness of 1.5 mm) have about a 2% land use efficiency penalty, but have better mechanical stability (lower stress and deflections), are easier to install and have reduced material economic costs compared to conventional frames. The results are promising for the use of the new PV frame designs for distributed manufacturing targeted at specific applications.

Sadat, S. A., Vandewetering, N., and Pearce, J. (2023). Mechanical and economic analysis of conventional aluminum photovoltaic module frames, frames with side holes, and open-source downward-fastened frames for non-traditional racking. ASME. J. Sol. Energy Eng. doi: https://doi.org/10.1115/1.4063493 [ academia open access] preprint

Solar photovoltaic wood racking mechanical design for trellis-based agrivoltaics[edit | edit source]

Using a trellis to plant vegetables and fruits can double or triple the yield per acre as well as reduce diseases/pests, ease harvesting and make cleaner produce. Cultivars such as cucumbers, grapes, kiwi, melons, peas, passion fruit, pole beans, pumpkins, strawberries, squash, and tomatoes are all grown with trellises. Many of these cultivars showed increased yield with partial shading with semi-transparent solar photovoltaic (PV) systems. To further increase the efficiency of trellis-based growing systems, this study investigates novel low-cost, open-source, sustainable, wood-based PV racking designs for agrivoltaic applications. Design calculations are made to ensure these racks exceed Canadian building code standards, which with snow loads surpass those of most of the world. A complete bill of materials, fabrication instructions, and proof-of-concept prototypes are provided for three system topographies (sloped, T-shaped and inverse Y) along with economic analysis. In addition, to being cost competitive, the designs can act as trellis supports and be used for irrigation/fertigation purposes. The results indicate that these racking structures have enormous promise both agriculturally and energetically. If employed on only grape farms inside Canada, 10 GW of PV potential is made available, which is more than twice the total current installed PV in Canada.

Jamil U, Vandewetering N, Pearce JM (2023) Solar photovoltaic wood racking mechanical design for trellis-based agrivoltaics. PLOS ONE 18(12): e0294682. https://doi.org/10.1371/journal.pone.0294682 academia open access

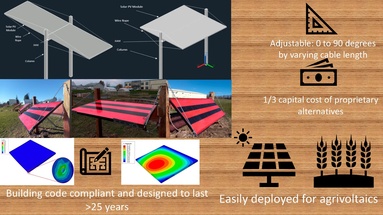

Wood- and Cable-Based Variable Tilt Stilt-Mounted Solar Photovoltaic Racking System[edit | edit source]

The prohibitive costs of small-scale solar photovoltaic (PV) racks decrease PV adoption velocity. To overcome these costs challenges, an open hardware design method is used to develop two novel variable tilt racking designs. These are the first stilt-mounted racking designs that allow for the manual change of the tilt angle from zero to 90 degrees by varying the length of cables. The racks are designed using the calculated dead, wind, and snow loads for Canada as a conservative design for most of the rest of the world. Structural capacities of the wooden members are then ascertained and the resisting bending moment, shear force, tensile force, and compressive force is calculated for them. A structural and truss analysis is performed to ensure that the racking design withstands the applicable forces. Moreover, the implications of changing the tilt angle on the wooden members/cables used to build the system are also determined. The systems offer significant economic savings ranging from one third to two thirds of the capital expenses of the commercially available alternatives. In addition, the racking designs are easy-to-build and require minimal manufacturing operations, which increases their accessibility. The stilt-mounted designs can be employed for agrivoltaic settings while allowing farm workers shaded, ergonomic access to perform planting, weeding, and harvesting. Jamil, U.; Vandewetering, N.; Sadat, S.A.; Pearce, J.M. Wood- and Cable-Based Variable Tilt Stilt-Mounted Solar Photovoltaic Racking System. Designs 2024, 8, 6. https://doi.org/10.3390/designs8010006 preprint

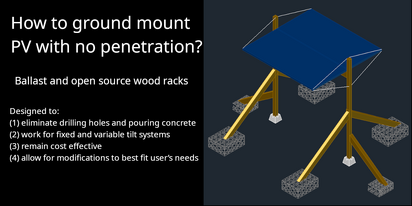

Ballast-Supported Foundation Designs for Low-Cost Open-Source Solar Photovoltaic Racking[edit | edit source]

Although solar photovoltaic (PV) system costs have declined, capital cost remains a barrier to widespread adoption. Do-it-yourself (DIY) system designs can significantly reduce labor costs, but if they are not attached to a building structure, they require ground penetrating footings. This is not technically and economically feasible at all sites. To overcome these challenges, this study details systems designed to (1) eliminate drilling holes and pouring concrete, (2) propose solutions for both fixed and variable tilt systems, (3) remain cost effective, and (4) allow for modifications to best fit the user’s needs. The ballast-supported foundations are analyzed for eight systems by proposing two separate ballast designs: one for a single line of post systems, and one for a double line of post systems, both built on a 4-kW basis. The results of the analysis found that both designs are slightly more expensive than typical in-ground concrete systems by 25% (assuming rocks are purchased at a landscaping company), but the overall DIY system’s costs remain economically advantageous. Sensitivity analyses are conducted to show how modifications to the dimensions influence the weight of the system and thus change the economic value of the design, so users can trade dimensional freedom for cost savings, and vice versa. Overall, all wood-based PV racking system designs provide users with cost-effective and easy DIY alternatives to conventional metal racking, and the novel ballast systems presented provide more versatility for PV systems installations.

Vandewetering, N.; Jamil, U.; Pearce, J.M. Ballast-Supported Foundation Designs for Low-Cost Open-Source Solar Photovoltaic Racking. Designs 2024, 8, 17. https://doi.org/10.3390/designs8010017 academia open access, preprint

Other Involvement[edit | edit source]

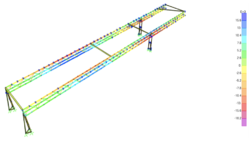

Lead Captain of the Western Engineering Steel Bridge Team (WESB).

The Western Engineering Steel Bridge team (WESB) competes in the Canadian Steel Bridge Competition annually against schools from all over the world to build the most cost-effective & structurally efficient bridge possible.

2023-2024 (Lead Captain): This year I will manage and oversee the design, fabrication, logistics, and finances of the team to develop the best possible bridge for the competition in Laval, Quebec. I assign duties to a team of 8 executives and 30+ general members to provide everyone a learning opportunity in the bridge building process.

2022-2023 (External Advisor): As I was off on my long term co-op with the MTO, I remained on the team as an external advisor to provide the team with assistance in analysis & design. I then built the bridge in the construction competition. The team came 2nd in oral presentation, 3rd in stiffness, and 3rd in structural efficiency.

2021-2022 (Analysis Lead): I was the analysis lead for WESB, in which I calculated critical stresses and deflections in a 21' steel bridge design using hand calculations and finite element analysis. I tutored a team of students on structural analysis and the basics of SAP 2000. The team conducted a prototype load test on two 3'6" sections, where I interpreted the stress-strain results to add accurate modified spring stiffnesses to the FEA model. I represented WESB at the Canadian National Steel Bridge Competition in May 2022. I presented our design to a panel of professional engineers, and was a bridge builder in the construction competition. The team came 1st in bridge aesthetics, 2nd in oral presentation, and 4th overall.

Literature Reviews[edit | edit source]

Canadian PV Racking System Standards Literature Review

Literature Review: Plastic Composites as a Structural Material

Canadian policy of PV systems on rooftops