- non parametric

- not looped

- no holes for permanent fixturing

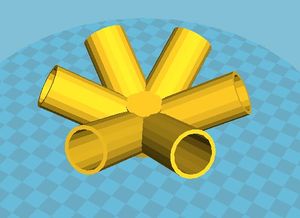

Tent Vertex Joint[edit | edit source]

Project developed by User:jcismith

Abstract[edit | edit source]

The purpose of this build was to make it easier and more convenient for individuals around the world to construct shelters with the resources available to them. The tent vertex joint accomplishes this by providing a sturdy point to join multiple poles for constructing a tent.

Bill of Materials[edit | edit source]

- Filament

- Design files (OpenSCAD and STL): | Youmagine Link

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

Skills and knowledge needed[edit | edit source]

- Knowledge of OpenSCAD is needed to manipulate the vertex joint if necessary.

Technical Specifications and Assembly Instructions[edit | edit source]

Print Directions[edit | edit source]

There is one .stl file for this print available to download.

Layer Height[edit | edit source]

It is recommended to print at a layer height of 0.1mm for a good quality vertex joint printed accurately.

Speed[edit | edit source]

It is good practice to print at slow speeds when producing quality prints, especially with this print due to the angle of the pole sockets. For the print above I used 40mm/s.

Temperature[edit | edit source]

I used Hatchbox 1.75mm PLA to make this print. A good temperature to print at with this filament is 185 degrees celsius.

Fill[edit | edit source]

I used 25% infill to ensure I made a strong, relatively light, good quality print.

Support Material[edit | edit source]

I printed with support material everywhere (touching the build plate and within the part itself) to maintain good quality when printing the angled pole sockets.

Removing Support Structure[edit | edit source]

- Using needle nose pliers, grab and tear support structure off from the pole sockets.

- Once all or most of the support structure is removed, sand until desired finish is achieved.

Print Temperature[edit | edit source]

For the PLA I print at 185 degrees Celsius, which provides me with precision printing and minimizes maintenance issues.

Assembly Time Estimate[edit | edit source]

N/A

Common Problems and Solutions[edit | edit source]

TBD

- Print Times (Varies on size of tent joint)

- Vertex Joint pictured to the right - ~14 hrs

- Assembly

- N/A

Common Problems and Solutions[edit | edit source]

- TBD

Cost savings[edit | edit source]

- Cost estimate uses the base STL files on Youmagine. Varying buckle sizes can result in different costs and savings due to the parametric nature of the project.

- Total cost: $1.65 (82 grams PLA)

- Commercial Part: ~$10 [1]

- Approximate savings of $8.35 (83.5% savings)