The pocket wrench is an excellent example of OSAT. Wrenches are a universal necessity, especially in third world countries where buying something new, rather than repairing something, is seldom an option. In addition to this, this wrench is small and cheap to make.

Bill of Materials[edit | edit source]

- Any 3D printable plastic

- The link to download this design can be found here [1]

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

Skills and knowledge needed[edit | edit source]

- No special skills were used to produce this wrench, other than basic 3D printing knowledge.

Technical Specifications and Assembly Instructions[edit | edit source]

- My print was made by extruding the PLA at 240C. I used this high of a temperature because my 3D printer is located in a room that is not heated, and as such, higher extrusion temperatures are needed to allow the filament to extrude properly. The print was made using a 60% hexagonal infill, this allows for the structure to maintain its rigidity, and be used for the application. There is no assembly process, as the design is one simple printed part.

- The print time on a delta printer was around 2 hours, using 37g of filament.

- There is no necessary assembly involved in the finished product.

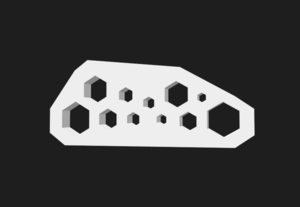

- A picture of the CAD Drawing is located to the right.

Common Problems and Solutions[edit | edit source]

The only foreseeable problem with this print is the accuracy of the smaller mm bolt holes. The best way to overcome these issues is to heat the correct bolt up to an extremely high temperature and forcing it through the corresponding wrench holes. This will allow the wrench to take a form fitting shape to the required bolt size. If the print is accurate enough there will be no further post processing necessary to finish the design.

Cost savings[edit | edit source]

- The total cost to print this design is around $1.50

- Commercial equivalent, $20+ [2]

- 92.5% Savings

Benefited Internet Communities[edit | edit source]

- DIY [3]