Lightweight combination wrenches are simple enough to guarantee a usable print with at least one end of the wrench. The OpenSCAD script can easily be modified to generate custom sizes in metric and add additional features if the user wishes. These wrenches are easy to carry, relatively durable, and much cheaper than conventional options. They can be made with locally available materials in PLA, ABS, or other filaments, and could be used to service the printer itself.

Someone may need only one or two particular wrenches to work on a vehicle, and individual wrenches are more affordable than an entire set (but the entire plastic wrench set is also much cheaper and lighter than a conventional wrench set). Although this wrench does generate a small amount of waste resulting from the support for the angled box end, ideally this plastic could be saved and recycled using a Recyclebot. (This design choice was also made because non-angled 3D printable combination wrenches already exist.)

Adjustable wrenches have been used as tests to show abilities of 3D printers,[1] however data is not available on field usage of plastic wrenches and their usefulness.

Bill of Materials[edit | edit source]

- Based on printer capabilities, cost, availability.

- Parts shown printed in PLA. ABS is probably best.

- File:Parametric combo wrench.scad

- Editable OpenSCAD file for making different size wrenches

- 15, 13, 6, and 3mm wrenches also in STL on Thingiverse

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

- Utility/hobby knife or similar (small saw)

- Pliers optional but helpful

Skills and knowledge needed[edit | edit source]

- Basic knowledge of your 3D printer

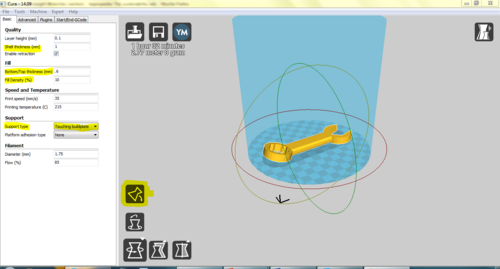

- How to use a slicing program to generate gcode

- Basic OpenSCAD skills to edit the file to change sizes

Technical Specifications and Assembly Instructions[edit | edit source]

Time Estimates[edit | edit source]

- Varies based on wrench size

- 13mm wrench ~1.5 hours printing plus ~20 minutes assembly

- 3mm wrench 10 minutes printing plus ~15 minutes assembly

Printing[edit | edit source]

- Slicing program - load model, lay flat

- With support, touching buildplate

- Wall thickness, top/bottom thickness ~1mm

- Fill at least 10%

Finishing[edit | edit source]

- Remove support on box end with knife/pliers/etc. (can be saved and used with Recyclebot v2.3)

- Smooth underside of wrench if necessary

-

Removing support material.

-

Some of the support material removed.

-

Smoothing the bottom of the handle.

-

Handle after smoothing.

Common Problems and Solutions[edit | edit source]

- Box end not proper size (ie round inside, not hexagonal)

- Increase print quality

- Thinner layers

- Slower print speed

- Change extrusion rate

- Not sticking to print bed

- Clean bed and reapply glue/solvent

- Support hard to remove

- Pliers useful for ripping off support

- Should not negatively affect usability

- Clean up with sharp knife

Cost savings[edit | edit source]

- Commercial 22-piece combination wrench set: 28.99 USD[2]

- ~1.30 USD per wrench

- 13mm PLA wrench ~8g

- 3mm PLA wrench ~2g

- PLA ~30 USD/kg

- ~0.30 USD per wrench (depending on size)

- 1 USD per wrench saved on average

- 77% cost savings in PLA

- Same approximate savings in ABS given ~35 USD/kg

References[edit | edit source]

- ↑ web page: Amazing 3D printer in action: Watch a working wrench being made from powder, (2012). Available: http://www.dailymail.co.uk/sciencetech/article-2117570/Amazing-3D-printer-action-Watch-working-wrench-printed-powder.html

- ↑ Amazon product page, (2014). Available: http://www.amazon.com/Wilmar-W1069-Metric-Polished-22-Piece/dp/B000FW6354/ref=lp_553412_1_3?s=power-hand-tools&ie=UTF8&qid=1417531300&sr=1-3