Biking is not only an enjoyable hobby or exercise, but a practical and sustainable way of getting where you need to go. Biking at night can be especially dangerous which is why many places require a light to be mounted to the front and back of any bicycle. These lights can be needlessly expensive, so I designed a customizable mount that can be used with any standard flashlight. This, paired with the many other parts designed by my colleagues, will allow anybody to print their own bicycle, making for a cheap and sustainable method of transportation.

Bill of Materials[edit | edit source]

- Flashlight

- Kg of filament

- Part Files: File:Light Mount.scad, File:Light Mount 2.scad

- STL Files: YouMagine

- M3 Nut and bolt

- M3 Hex Wrench

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

- M3 Hex Wrench

Skills and knowledge needed[edit | edit source]

- Basic knowledge of 3D printing

Technical Specifications and Assembly Instructions[edit | edit source]

- Print Specifications:

- Material: PLA

- Layer Height: 0.1 mm

- Wall/Top/Bottom Thickness: 0.8 mm

- Infill: 15%

- Extrusion Temperature: 200˚C

- Print Speed: 60 mm/s

- Support: Everywhere at 50˚

- Bed Adhesion: Skirt

- Print time estimate: 1 Hour 35 Minutes

- Assembly Instructions:

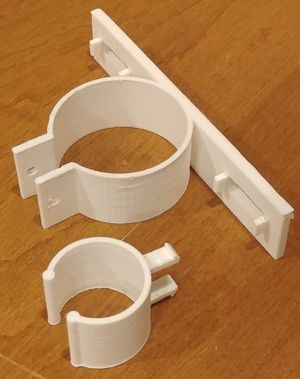

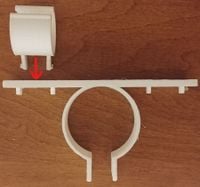

- Place snap-fit rings in base mount slots.

- Press down firmly until the tabs snap into place. For larger lights requiring more support, print a second ring and repeat this process for the back mounting slot.

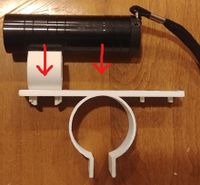

- Place the light into the snap-fit rings by firmly pushing it into the opening.

- Take the handlebar mounting hole and place it around the handlebars. The mount should flex enough to fit around the bar.

- Place a 20mm long M3 bolt through the holes at the opening of the mount and secure with an M3 nut. Keep it loose enough to rotate the mount about the bar

- Adjust the light to the desired level and tighten the bolt to an M3 hex wrench.

- Assembly time estimate: 5 minutes

Common Problems and Solutions[edit | edit source]

- Size the flashlight hole and handlebar hole to be slightly smaller than the actual light and handlebar. This will allow for a proper, tight fit.

- Ream the M3 through holes to clear them of all debris.

Cost savings[edit | edit source]

- If your solution is not a low cost one then it is not really appropriate.

- Estimated Cost:

- Flashlight: $3.44

- Printed parts: $0.14

- Hardware: $0.06

- Total Cost: $3.64

- Commercial equivalent: Front Light: $64.95

- Savings: $61.35 or 94%