Los materiales compuestos W se utilizan ampliamente en la industria aeronáutica y han permitido a los ingenieros superar los obstáculos que se han encontrado al utilizar los materiales individualmente. Los materiales constituyentes conservan sus identidades en los compuestos y no se disuelven ni se fusionan completamente entre sí. Juntos, los materiales crean un material "híbrido" que tiene propiedades estructurales mejoradas.

El desarrollo de materiales compuestos ligeros y resistentes a altas temperaturas permitirá la materialización de la próxima generación de diseños aeronáuticos económicos y de alto rendimiento. El uso de dichos materiales reducirá el consumo de combustible, mejorará la eficiencia y reducirá los costos operativos directos de las aeronaves.

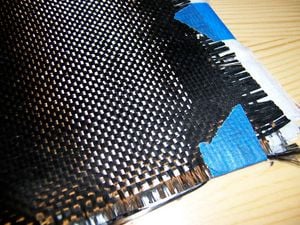

Los materiales compuestos pueden adoptar diversas formas y, si se desea, las fibras pueden enrollarse firmemente para aumentar su resistencia. Una característica útil de los materiales compuestos es que pueden disponerse en capas, de modo que las fibras de cada capa discurran en una dirección diferente. Esto permite a un ingeniero diseñar estructuras con propiedades únicas. Por ejemplo, una estructura puede diseñarse de modo que se doble en una dirección, pero no en otra. [2]

Contenido

Síntesis de compuestos básicos

En un compuesto básico, un material actúa como matriz de soporte, mientras que otro material se basa en este andamiaje de base y refuerza todo el material. La formación del material puede ser un proceso costoso y complejo. En esencia, se coloca una matriz de material base en un molde a alta temperatura y presión. Luego se vierte un epoxi o resina sobre el material base, creando un material resistente cuando el material compuesto se enfría. El compuesto también se puede producir incrustando fibras de un material secundario en la matriz base.

Los materiales compuestos tienen una buena resistencia a la tracción y a la compresión, lo que los hace adecuados para su uso en la fabricación de piezas de aeronaves. La resistencia a la tracción del material proviene de su naturaleza fibrosa. Cuando se aplica una fuerza de tracción, las fibras dentro del material compuesto se alinean con la dirección de la fuerza aplicada, lo que le da su resistencia a la tracción. La buena resistencia a la compresión se puede atribuir a las propiedades adhesivas y de rigidez del sistema de matriz base. La función de la resina es mantener las fibras como columnas rectas y evitar que se deformen.

Aviación y materiales compuestos

Los materiales compuestos son importantes para la industria aeronáutica porque proporcionan una resistencia estructural comparable a las aleaciones metálicas, pero con un peso más ligero. Esto conduce a una mejor eficiencia de combustible y al rendimiento de una aeronave. [3] [4]

El papel de los materiales compuestos en la industria de la aviación

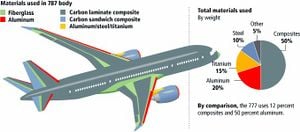

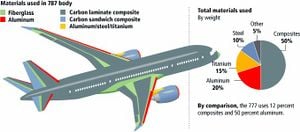

La fibra de vidrio es el material compuesto más común y consiste en fibras de vidrio incrustadas en una matriz de resina. La fibra de vidrio se utilizó ampliamente por primera vez en la década de 1950 para barcos y automóviles. La fibra de vidrio se utilizó por primera vez en el avión de pasajeros Boeing 707 en la década de 1950, donde comprendía aproximadamente el dos por ciento de la estructura. Cada generación de nuevos aviones construidos por Boeing tuvo un mayor porcentaje de uso de materiales compuestos; el más alto fue el 50% de uso de materiales compuestos en el 787 Dreamliner .

El Boeing 787 Dreamliner será el primer avión comercial en el que los principales elementos estructurales estén fabricados con materiales compuestos en lugar de aleaciones de aluminio. [1] En este avión se dejarán de utilizar los arcaicos compuestos de fibra de vidrio para pasar a utilizar compuestos más avanzados de laminado de carbono y sándwich de carbono. Se han encontrado problemas con el cajón del ala del Dreamliner, que se han atribuido a una rigidez insuficiente en los materiales compuestos utilizados para construir la pieza. [1] Esto ha provocado retrasos en las fechas de entrega iniciales del avión. Para resolver estos problemas, Boeing está reforzando los cajones del ala añadiendo nuevos soportes a los cajones del ala ya construidos, al tiempo que modifica los cajones del ala que aún están por construir. [1]

Ensayos de materiales compuestos

Se ha comprobado que es difícil modelar con precisión el rendimiento de una pieza fabricada con materiales compuestos mediante simulación por ordenador debido a la naturaleza compleja del material. Los materiales compuestos suelen superponerse unos a otros para aumentar su resistencia, pero esto complica la fase de prueba previa a la fabricación, ya que las capas están orientadas en direcciones diferentes, lo que dificulta predecir cómo se comportarán durante la prueba. [1]

También se pueden realizar pruebas de esfuerzo mecánico en las piezas. Estas pruebas comienzan con modelos a pequeña escala, luego pasan a partes de la estructura cada vez más grandes y, finalmente, a la estructura completa. Las piezas estructurales se colocan en máquinas hidráulicas que las doblan y tuercen para imitar tensiones que van mucho más allá de las peores condiciones esperadas en vuelos reales.

Factores de uso de materiales compuestos

La reducción de peso es la mayor ventaja del uso de materiales compuestos y es uno de los factores clave en las decisiones sobre su selección. Otras ventajas incluyen su alta resistencia a la corrosión y su resistencia a los daños por fatiga. Estos factores juegan un papel en la reducción de los costos operativos de la aeronave a largo plazo, mejorando aún más su eficiencia. Los materiales compuestos tienen la ventaja de que se pueden moldear en casi cualquier forma mediante el proceso de moldeo, pero esto agrava el ya difícil problema del modelado.

Una de las principales desventajas del uso de materiales compuestos es que se trata de un material relativamente nuevo y, por lo tanto, tiene un coste elevado. Este elevado coste también se debe a que el proceso de fabricación requiere mucha mano de obra y suele ser complejo. Los materiales compuestos son difíciles de inspeccionar para detectar defectos y algunos absorben la humedad.

El aluminio, por el contrario, a pesar de ser más pesado, es fácil de fabricar y reparar. Puede abollarse o perforarse y aun así mantenerse unido. Los materiales compuestos no son así: si se dañan, requieren una reparación inmediata, lo que resulta difícil y costoso.

Ahorro de combustible con peso reducido

El consumo de combustible depende de varias variables, entre ellas: peso seco del avión, peso de la carga útil, antigüedad del avión, calidad del combustible, velocidad del aire, climatología, entre otras. El peso de los componentes de los aviones fabricados con materiales compuestos se reduce aproximadamente en un 20%, como en el caso del 787 Dreamliner. [4]

A continuación se realizaráun cálculo de muestra del ahorro total de combustible con una reducción del peso en vacío del 20% para un avión Airbus A340-300.

Los valores de muestra iniciales para este estudio de caso se obtuvieron de una fuente externa. [5]

Dado:

- Peso operativo vacío (OEW): 129.300 kg

- Peso máximo sin combustible (MZFW): 178 000 kg

- Peso máximo de despegue (MTOW): 275.000 kg

- Alcance máximo con peso máximo: 10 458 km

A partir de las cifras dadas anteriormente se pueden calcular otras cantidades:

- Peso máximo de carga = MZFW - OEW = 48,700 kg

- Peso máximo del combustible = MTOW - MZFW = 97.000 kg

Por lo tanto, podemos calcular además el consumo de combustible en kg/km en función del peso máximo del combustible y la autonomía máxima = 97 000 kg/10 458 km = 9,275 kg/km.

A continuación se muestra el cálculo del ahorro de combustible previsto con una reducción de peso del 20%, que solo reducirá el valor OEW en un 20%:

- OEW(nuevo) = 129.300 kg * 0,8 = 103.440 kg, lo que equivale a un ahorro de peso de 25.860 kg.

Suponiendo que el peso de la carga y el combustible permanecen constantes:

- MZFW(nuevo) = MZFW - 25.680 kg = 152.320 kg

- MTOW(nuevo) = MTOW - 25.680 kg = 249.320 kg

La masa de combustible de 97.000 kg tiene un MTOW reducido y, por lo tanto, tendrá un mayor alcance porque el peso máximo y el alcance máximo son cantidades inversamente proporcionales.

Usando proporciones simples para calcular el nuevo rango:

249,320agramo275,000agramo=10,458ametroincógnitaametro{\displaystyle {\frac {249,320kg}{275,000kg}}={\frac {10,458km}{Xkm}}}

Resolviendo X obtenemos un nuevo rango de:

- X = 11.535,18 km

Esto da un nuevo valor de consumo de combustible con peso reducido = 97.000 kg/11.535,18 km = 8,409 kg/km.

Para ponerlo en perspectiva, en un recorrido de 10.000 kilómetros habrá un ahorro aproximado de combustible de 8.660 kg con una reducción del 20% del peso en vacío.

Impacto ambiental

Se está produciendo un cambio cada vez más marcado hacia la ingeniería ecológica . La sociedad actual presta cada vez más atención al medio ambiente. Esto también se aplica a la fabricación de materiales compuestos.

Como se mencionó anteriormente, los materiales compuestos tienen un peso más ligero y valores de resistencia similares a los de los materiales más pesados. Cuando se transporta un material compuesto más ligero o se lo utiliza en una aplicación de transporte, existe una carga ambiental menor en comparación con las alternativas más pesadas. Los materiales compuestos también son más resistentes a la corrosión que los materiales de base metálica, lo que significa que las piezas durarán más. [7] Estos factores se combinan para hacer que los materiales compuestos sean buenos materiales alternativos desde una perspectiva ambiental.

Los materiales compuestos producidos convencionalmente están hechos de fibras y resinas derivadas del petróleo y no son biodegradables por naturaleza. [8] Esto presenta un problema importante, ya que la mayoría de los compuestos terminan en un vertedero una vez que finaliza el ciclo de vida de un compuesto. [8] Se están realizando investigaciones importantes en compuestos biodegradables que están hechos de fibras naturales. [9] El descubrimiento de materiales compuestos biodegradables que se pueden fabricar fácilmente a gran escala y tienen propiedades similares a los compuestos convencionales revolucionará varias industrias, incluida la industria de la aviación.

Una opción alternativa para contribuir a los esfuerzos medioambientales sería reciclar piezas usadas de aeronaves fuera de servicio. La "desingeniería" de una aeronave es un proceso complejo y costoso, pero puede ahorrar dinero a las empresas debido al alto coste de la compra de piezas de primera mano. [6]

Los materiales compuestos del futuro

Compuestos de matriz cerámica

La Administración Nacional de Aeronáutica y del Espacio (NASA) está realizando importantes esfuerzos para desarrollar materiales compuestos ligeros y resistentes a altas temperaturas para su uso en piezas de aeronaves. Según cálculos preliminares, se prevén temperaturas de hasta 1650 °C para las entradas de la turbina de un motor conceptual. [3] Para que los materiales resistan tales temperaturas, se requiere el uso de compuestos de matriz cerámica (CMC). El uso de CMC en motores avanzados también permitirá un aumento de la temperatura a la que se puede operar el motor, lo que conduce a un mayor rendimiento. [10] Aunque los CMC son materiales estructurales prometedores, sus aplicaciones son limitadas debido a la falta de materiales de refuerzo adecuados, las dificultades de procesamiento, la vida útil y el costo.

Fibras de seda de araña

La seda de araña es otro material prometedor para el uso en materiales compuestos. La seda de araña exhibe una alta ductilidad, lo que permite estirar una fibra hasta el 140% de su longitud normal. [11] La seda de araña también mantiene su resistencia a temperaturas tan bajas como -40 °C. [11] Estas propiedades hacen que la seda de araña sea ideal para su uso como material de fibra en la producción de materiales compuestos dúctiles que mantendrán su resistencia incluso a temperaturas anormales. Los materiales compuestos dúctiles serán beneficiosos para una aeronave en partes que estarán sujetas a tensiones variables, como la unión de un ala con el fuselaje principal. La mayor resistencia, tenacidad y ductilidad de un compuesto de este tipo permitirá que se apliquen mayores tensiones a la pieza o unión antes de que se produzca una falla catastrófica. Los compuestos a base de seda de araña sintética también tendrán la ventaja de que sus fibras serán biodegradables.

Se han realizado muchos intentos fallidos de reproducir la seda de araña en el laboratorio, pero aún no se ha logrado una resíntesis perfecta. [12]

Chapas de acero compuestas híbridas

Otro material prometedor es el acero inoxidable, fabricado con materiales compuestos, fibras nanotecnológicas y madera contrachapada. Las láminas de acero están hechas del mismo material y se pueden manipular y mecanizar exactamente de la misma manera que el acero convencional, pero son un porcentaje más ligeros con la misma resistencia, lo que resulta especialmente valioso para la fabricación de vehículos. La empresa sueca Lamera, cuya patente está en trámite, es una escisión de la investigación de Volvo Industries.

Conclusión

Debido a su mayor relación resistencia-peso, los materiales compuestos tienen una ventaja sobre los materiales metálicos convencionales, aunque actualmente su fabricación es cara. Hasta que se introduzcan técnicas que reduzcan los costes iniciales de implementación y se aborde el problema de la no biodegradabilidad de los compuestos actuales, este material relativamente nuevo no podrá sustituir por completo a las aleaciones metálicas tradicionales.

Referencias

- ↑Saltar a:1.0 1.1 1.2 1.3 1.4 1.5 Modelado de superficies para materiales compuestos - SIAG GD - Recuperado de http://www.ifi.uio.no/siag/problems/grandine/

- ↑ De la A a la Z de los materiales: materiales compuestos: una introducción básica - Recuperado de http://web.archive.org/web/20080806113558/http://www.azom.com/details.asp?ArticleID=962

- ↑Saltar a:3.0 3.1 INI International - Key to Metals - Recuperado de http://www.keytometals.com/Article103.htm

- ↑Saltar a:4.0 4.1 El 787 Dreamliner de Boeing tiene un problema de material compuesto - Zimbio - Recuperado de http://web.archive.org/web/20101002101128/http://www.zimbio.com:80/Boeing+787+Dreamliner/articles/18/Boeing+787+Dreamliner+composite+problem

- ↑ Peeters, PM et al. - Eficiencia de combustible de los aviones comerciales (pág. 16) - Recuperado de http://www.transportenvironment.org/docs/Publications/2005pubs/2005-12_nlr_aviation_fuel_efficiency.pdf

- ↑Saltar a:6.0 6.1 National Geographic Channel - Hecho por el hombre: Avión - Recuperado de http://channel.nationalgeographic.com/series/man-made/3319/Photos#tab-Videos/05301 00

- ↑ Un estudio sobre el impacto ambiental de los materiales compuestos - Recuperado en http://web.archive.org/web/20060923103650/http://www.plastkemiforetagen.se/Publikationer/PDF/Composite_materials_in_an_environmental_perspective.pdf

- ↑Saltar a:8.0 8.1 Textile Insight - Compuestos textiles ecológicos - Recuperado de http://www.textileinsight.com/articles.php?id=453

- ↑ De la A a la Z de los materiales: materiales compuestos de alto rendimiento producidos a partir de plásticos biodegradables reforzados con fibras naturales. Recuperado de http://www.azom.com/news.asp?newsID=13735

- ↑ R. Naslain - Université Bordeaux - Composites de matriz cerámica - Recuperado en http://web.archive.org/web/20101122114453/http://www.mpg.de/pdf/europeanWhiteBook/wb_materials_213_216.pdf

- ↑Saltar a:11.0 11.1 Departamento de Química - Universidad de Bristol - Recuperado en http://www.chm.bris.ac.uk/motm/spider/page2.htm

- ↑ Wired Science - Las arañas producen seda dorada - Recuperado de http://www.wired.com/wiredscience/2009/09/spider-silk/