A bike is a very useful mode of transportation that many people in first-world countries take for granted. There has been a goal set to create a cheap bike using primarily 3D printed parts. This bike pedal is a good prototype for what the possibilities are for this project. This pedal is fully 3D printed and clips together around a bar/axle. The goal is that this pedal would be easy to switch out and allows for rotation around the axle but not in other directions. This is still a rough prototype and would need more work to be implemented fully onto the bike.

Possible additions to bike pedal:

- Add screw attachment at the end of the axle

- Develop more secure clips (these were tough to model and print)

Bill of Materials[edit | edit source]

- Plastic Filament (PLA preferred)

- All files (FreeCAD and.stl) can be found on Youmagine at: https://www.youmagine.com/designs/bike-pedal-38-29

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

- Knife of some sort to clean up parts

Skills and Knowledge Necessary to Make the OSAT[edit | edit source]

- Be sure you are able to load an STL into a slicer and orient it the correct way

- Basic understanding of bike pedals

Technical Specifications and Assembly Instructions[edit | edit source]

-

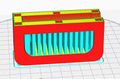

1. After downloading all.stl files from Youmagine, begin by printing two halves of the pedal with the orientation shown. Ensure there is enough support. Print time: 3 hrs 18 mins each half at 70 mm/s

-

2. Print six clips with the orientation shown. Print time: 1 min each at 70 mm/s

-

3. Print one axle with the orientation shown (for smoothest surfaces). Print time: 38 mins at 70 mm/s

-

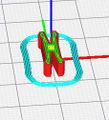

4. Place all six clips and the axle on one half of the pedal as shown.

-

5. Place second half of pedal on top as shown.

-

6. Apply force to snap clips into place. The final product is as shown. Assembly should take a total of no more than 2 minutes.

Common Problems and Solutions[edit | edit source]

- Don't forget to put support everywhere on the pedal halves. Be sure to select "Everywhere" instead of "Touching Buildplate".

- Ensure all pieces are printed with the orientation shown.

Cost savings[edit | edit source]

- The cost to print the full pedal is approximately $2.50

- Walmart sells two pedals for $7.99 [1]

- Savings are $3.00 per two pedals which is savings of 37.5%