This skills module allows medical officers and surgeons who are not orthopedic specialists to become confident and competent in performing bicortical drilling as part of modular external fixation procedures for open tibial shaft fractures performed in regions without specialist coverage.

Learning Objectives[edit | edit source]

By the end of this module, learners will be able toː

- Direct an assistant to perform irrigation while the learner is drilling to prevent thermal osteonecrosis

- Perform bicortical drilling with drill trajectory angles relative to the saggital plane (tibial crest) between 30-60 degrees into the safe zones of the tibia

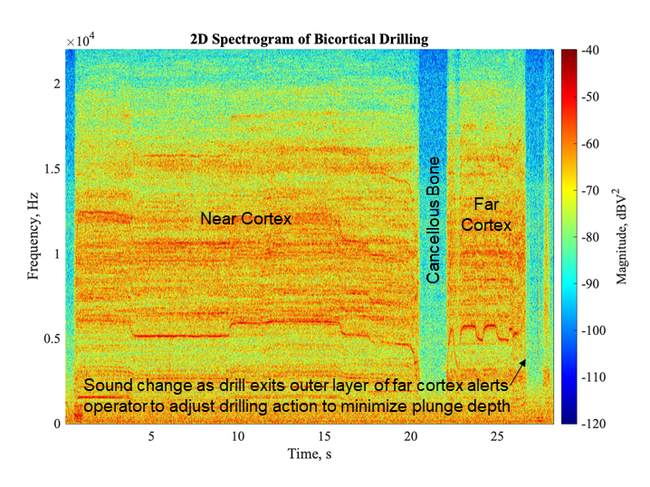

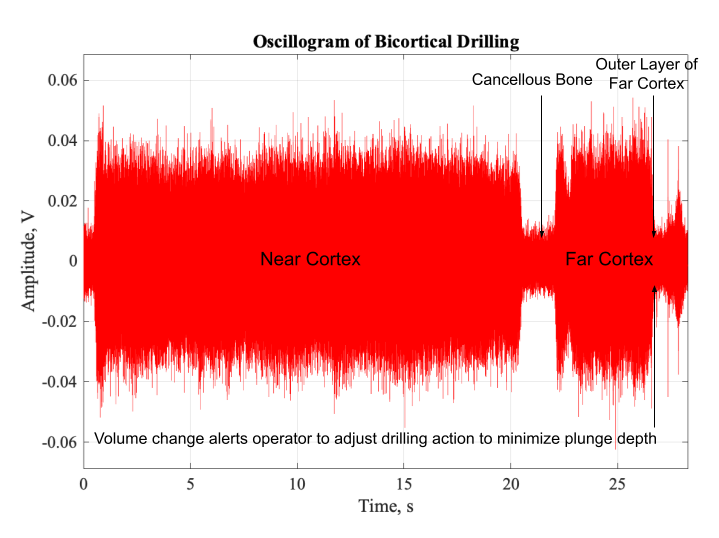

- Drill by sound and feel to identify when the drill bit penetrates the near cortex, cancellous bone, far cortex, and the outer layer of the far cortex

- Adjust drilling direction, speed, and applied force to minimize plunge

To overcome the drawbacks of 3D printed plastic melting at high drilling temperatures, this module trains the learner to irrigate during bicortical drilling, which is a standard orthopedic surgical practice to reduce the risk of thermal osteonecrosis.[1][2] This provides continuous cooling to prevent melting of the 3D printed plastic bone model.

Materials and Equipment[edit | edit source]

Tibial Shaft Simulator[edit | edit source]

The Tibial Shaft Simulator and Clay Backstop for Plunge Depth Measurement will be used in this module.

This Tibial Shaft Simulator uses the 3D Printed Adult Tibial Bone Model #3 which accurately simulates bone length and diameter, external contour, cross-sectional shape, bicortical anatomy, cortical hardness, cancellous bone porosity, and microstructure, and far cortex thickness for non-obese adults at left tibial shaft fracture pin drilling sites for modular external fixation.[3][4][5][6][7][8][9][10][11][12]

- This model features a semi-engraved model number, gender symbol, and drilling direction arrow on the base of the model to assist with model identification and proper orientation.

- The model has a vise attachment to allow the user to secure the model inside a standard vise clamp to maximize safety during simulation training. When a model is placed inside a standard vise clamp, the bone model will be properly positioned to simulate a patient in the supine position.

The Tibial Shaft Simulator teaches bicortical drilling skills useful for modular external fixation and that are transferable to the performance of other limb-saving and life-saving surgeries that require hardware stabilization and fixation.

Equipment[edit | edit source]

- Powered Orthopedic Surgical Drill with installed 4.0 mm Drill Bit

- Two additional 4.0 mm Drill Bits (purchased from local orthopedic surgical hardware vendor)

- 4.5 mm Combination Drill Sleeve

- Depth Gauge

Training Logbook[edit | edit source]

Please print out the Training Logbook below and write your name and date of training at the bottom of the page.

| # | Training Goal | Trial #1 Plunge Depth (in mm) | Trial #2 Plunge Depth (in mm) | Trial #3 Plunge Depth (in mm) | Average Plunge Depth for Trials #1 to #3 (in mm) |

|---|---|---|---|---|---|

| 1 | Irrigation | ||||

| 2 | Bicortical Drilling Skills Checklist |

| # | Action | Check box if response is "YES' |

|---|---|---|

| 1 | Check that the drill bit is sharp before use. | |

| 2 | Adjust operating room table to be at elbow level. | |

| 3 | Direct an assistant to perform irrigation to reduce thermal osteonecrosis. | |

| 4 | Maintain the drill parallel with your forearm to maintain better control of the drill. | |

| 5 | Hold the drill with your dominant hand and position the drill sleeve with your non-dominant hand. | |

| 6 | Normally, the drill sleeve is positioned directly on the bone. When training on the Tibial Shaft Simulator, you will need to hold the drill sleeve 3.0 mm above the bone model to avoid having plastic stands entangled in the drill sleeve. | |

| 7 | Start drilling the hole perpendicular to the bone surface. | |

| 8 | Once penetration starts, re-insert the drill into the initial entry point and adjust to the desired direction. | |

| 9 | The drill trajectory angle relative to the saggital plane (tibial crest) should be 30-60 degrees. |

| # | Training Goal | Trial #0 Plunge Depth (in mm) | Trial #1 Plunge Depth (in mm) | Trial #2 Plunge Depth (in mm) | Trial #3 Plunge Depth (in mm) | Average Plunge Depth for Trials #1 to #3 (in mm) |

|---|---|---|---|---|---|---|

| 1 | Drill by sound | |||||

| 2 | Drill by feel | |||||

| 3 | Drill by sound and feel |

| # | Trial #1 Plunge Depth (in mm) | Trial #2 Plunge Depth (in mm) | Trial #3 Plunge Depth (in mm) | Average Plunge Depth for Trials #1 to #3 (in mm) |

|---|---|---|---|---|

| 1 | ||||

| 2 | ||||

| 3 |

Learner's Nameː

Evaluator's Nameː

Date of Trainingː

Learning Bicortical Drilling Step-By-Step[edit | edit source]

- Irrigation is performed using sterile normal saline during drilling to reduce thermal osteonecrosis.[2]

- For this simulation training module, the learner will use water as simulated sterile normal saline to perform external irrigation and to also provide continuous cooling to prevent melting of the 3D printed plastic bone models.

- IMPORTANT: Surgical gloves should be worn by the learner during bicortical drilling skills training to simulate intraoperative tactile feedback.[13]

- Wear proper eye protection and gloves.

- Direct an assistant to use a syringe to irrigate the drill bit while drilling to cool the drill bit.

- Drill three consecutive bicortical holes in the 3D Printed Adult Tibial Bone Model #3.

- Check that the drill bit is sharp before use.[14][15]

- Adjust operating room table to be at elbow level.

- Direct an assistant to perform irrigation to reduce thermal osteonecrosis.[16]

- Maintain the drill parallel with your forearm to maintain better control of the drill.

- Hold the drill with your dominant hand and position the drill sleeve with your non-dominant hand. IMPORTANT: Normally, the drill sleeve is positioned directly on the bone. When training on the Tibial Shaft Simulator, hold the drill sleeve 3.0 mm above the bone model to avoid having plastic stands entangled in the drill sleeve.

- Start drilling the hole perpendicular to the bone surface.

- Once penetration starts, re-insert the drill into the initial entry point and adjust to the desired direction.[14]

- IMPORTANT: The drill trajectory angle relative to the saggital plane (tibial crest) should be between 30-60 degrees to ensure proper insertion of the modular external fixation pin into the safe zones of the tibia.

- Wear proper eye protection and gloves.

- Ask a colleague to evaluate you with the Bicortical Drilling Checklist in the Training Logbook.

- Direct an assistant to perform irrigation when drilling.

- Drill three consecutive bicortical holes in the 3D Printed Adult Tibial Bone Model #1 and use the sound changes and tactile feedback as the drill progresses through the outer layer of the far cortex to adjust the drilling action to minimize plunging.

Oscillogram of Bicortical Drilling of a Tibial Fracture

File:Bicortical Drilling of Tibial Fracture v2.0.wav

Play this audio file to identify the acoustic changes of the drill as it progresses through the near cortex, cancellous bone, and the outer layer of the far cortex, and is backed out of the drilled hole.

- Wear proper eye protection and gloves.

- Direct an assistant to perform irrigation when drilling.

- Drill one bicortical hole in 3D Printed Adult Tibial Bone Model #3 to identify the sound changes of the drill as it progresses through the near cortex, cancellous bone, and the outer layer of the far cortex.

- Drill three consecutive bicortical holes in the 3D Printed Adult Tibial Bone Model #3 and use the sound changes of the drill as it progresses through the outer layer of the far cortex to adjust the drilling action to minimize plunging.

- The tactile feel of the drill changes as it progresses through the near cortex, cancellous bone, and the outer layer of the far cortex.

- The operator will feel a "give" when the drill passes through the near cortex into the cancellous bone and again when the drill exits the outer layer of the far cortex.

- Wear proper eye protection and gloves.

- Direct an assistant to perform irrigation when drilling.

- Drill one bicortical hole in the 3D Printed Adult Tibial Bone Model #3 and pay attention to how the tactile feel changes as the drill progresses through the near cortex, cancellous bone, and the outer layer of the far cortex.

- Drill three consecutive bicortical holes in the 3D Printed Adult Tibial Bone Model #3 and use tactile feedback as the drill progresses through the outer layer of the far cortex to adjust the drilling action to minimize plunging.

Now it's time to put these two sensory inputs (sound and tactile feedback) together during bicortical drilling training!

2D and 3D Spectrograms of Bicortical Drilling of a Tibial Fracture<youtube>https://youtu.be/QT_H8rWQPSI</youtube>

File:Bicortical Drilling of Tibial Fracture v2.0.wav

Play the video and audio files simultaneously to identify the acoustic changes of the drill as it progresses through the near cortex, cancellous bone, and the outer layer of the far cortex, and is backed out of the drilled hole.

- Wear proper eye protection and gloves.

- Direct an assistant to perform irrigation when drilling three sets of three consecutive bicortical holes in the 3D Printed Adult Tibial Bone Model #3 to try to achieve the smallest plunge depth averaged over 3 trials.

- Remove the clay backstop from the Tibial Shaft Simulator and use the depth gauge to measure the plunge depths.

- Record the plunge depths and calculate the average plunge depth values in the Training Logbook.

Self assessment[edit | edit source]

Please fill out the printed Training Logbook for your records.

Acknowledgements[edit | edit source]

This work is funded by a grant from the Intuitive Foundation. Any research, findings, conclusions, or recommendations expressed in this work are those of the author(s), and not of the Intuitive Foundation.

References[edit | edit source]

- ↑ Werz SM, Zeichner SJ, Berg BI, Zeilhofer HF, Thieringer F. 3D printed surgical simulation models as educational tool by maxillofacial surgeons. Eur J Dent Educ. 2018;22(3):e500–5. https://doi.org/10.1111/eje.12332.

- ↑ 2.0 2.1 Timon C, Keady C. Thermal Osteonecrosis Caused by Bone Drilling in Orthopedic Surgery: A Literature Review. Cureus. 2019 Jul 24;11(7):e5226. doi: 10.7759/cureus.5226. PMID: 31565628; PMCID: PMC6759003.

- ↑ Ugochukwu EG, Ugbem LP, Ijomone OM, Ebi OT. Estimation of Maximum Tibia Length from its Measured Anthropometric Parameters in a Nigerian Population. J Forensic Sci Med [serial online] 2016 [cited 2021 Jun 27];2:222-8. Available from: https://www.jfsmonline.com/text.asp?2016/2/4/222/197928.

- ↑ U.S. Department of Health and Human Services — National Institutes of Health. Human tibia and fibula. [Internet]. Bethesda, (MD): NIH 3D Print Exchange; 2014 May 29 [cited 2021 Aug 17]. Available from: https://3dprint.nih.gov/discover/3DPX-000169.

- ↑ Gosman JH, Hubbell ZR, Shaw CN, Ryan TM. Development of cortical bone geometry in the human femoral and tibial diaphysis. Anat Rec (Hoboken). 2013 May;296(5):774-87. doi: 10.1002/ar.22688. Epub 2013 Mar 27. PMID: 23533061.

- ↑ Ultimaker. Ultimaker PLA Technical Data Sheet [Internet]. Ultimaker Support. [cited 2021 July 29]. Available from: https://support.ultimaker.com/hc/en-us/articles/360011962720-UltimakerPLA-TDS.

- ↑ Vian, Wei Dai and Denton, Nancy L., "Hardness Comparison of Polymer Specimens Produced with Different Processes" (2018). ASEE IL-IN Section Conference. 3. https://docs.lib.purdue.edu/aseeil-insectionconference/2018/tech/3.

- ↑ Society For Biomaterials 30th Annual Meeting Transactions, page 332. Femoral Cortical Wall Thickness And Hardness Evaluation. K. Calvert, L.A. Kirkpatrick, D.M. Blakemore, T.S. Johnson. Zimmer, Inc., Warsaw, IN.

- ↑ Meyers, M. A.; Chen, P.-Y. (2014). Biological Materials Science. Cambridge: Cambridge University Press. ISBN 978-1-107-01045-1.

- ↑ Forrest AM, Johnson AE, inventors; Pacific Research Laboratories, Inc., assignee. Artificial bones and methods of making same. United States patent 8,210,852 B2. Date issued 2012 Jul 3.

- ↑ National Institutes of Health Osteoporosis and Related Bone Diseases National Resource Center. What is Bone? [Internet]. Bethesda (MD): The National Institutes of Health (NIH); 2018. [Cited 2021 Aug 17]. Available from: https://www.bones.nih.gov/health-info/bone/bone-health/what-is-bone.

- ↑ Maeda K, Mochizuki T, Kobayashi K, Tanifuji O, Someya K, Hokari S, Katsumi R, Morise Y, Koga H, Sakamoto M, Koga Y, Kawashima H. Cortical thickness of the tibial diaphysis reveals age- and sex-related characteristics between non-obese healthy young and elderly subjects depending on the tibial regions. J Exp Orthop. 2020 Oct 6;7(1):78. doi: 10.1186/s40634-020-00297-9. PMID: 33025285; PMCID: PMC7538524.

- ↑ Ding A, Marmor M. Drilling Technique Can Minimize Plunging. J Orthop Trauma. 2019 Aug;33(8):e309-e312. doi: 10.1097/BOT.0000000000001490. PMID: 31045621.

- ↑ 14.0 14.1 John A. Ruder, Blake Turvey, Joseph R. Hsu, Brian P. Scannell, Effectiveness of a Low-Cost Drilling Module in Orthopaedic Surgical Simulation, Journal of Surgical Education, Volume 74, Issue 3, 2017, Pages 471-476, ISSN 1931-7204, https://doi.org/10.1016/j.jsurg.2016.10.010.

- ↑ Alajmo G, Schlegel U, Gueorguiev B, Matthys R, Gautier E. Plunging when drilling: effect of using blunt drill bits. J Orthop Trauma. 2012 Aug;26(8):482-7. doi: 10.1097/BOT.0b013e3182336ec3. PMID: 22391404.

- ↑ Timon C, Keady C. Thermal Osteonecrosis Caused by Bone Drilling in Orthopedic Surgery: A Literature Review. Cureus. 2019 Jul 24;11(7):e5226. doi: 10.7759/cureus.5226. PMID: 31565628; PMCID: PMC6759003.