(+category) |

Sophivorus (talk | contribs) m (Text replacement - "| instance-of = " to "| type = ") |

||

| (13 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

[[File:BiocharRocketStove.JPG|thumb|Ed Revills' new stove design]] | |||

This is a [[Rocket stoves|rocket stove]] type design that uses small pieces of wood or other biomass as the insulation. | {{Project data | ||

| type = Rocket stove | |||

}} | |||

This stove was designed to provide a source of biochar for small scale growers while burning the gases given off form the char production to provide energy for space heating and cooking. | |||

This is a [[Rocket stoves|rocket stove]] type design that uses small pieces of wood or other biomass as the insulation. The heat produced by burning wood in the rocket stove causes the wood/biomass insulation in the surrounding chamber (retort) to undergo pyrolysis. The gases produced by the pyrolysis are fed into the stove and burnt, As air does not flow through the retort the wood held within turns into [[biochar]]/charcoal rather than burning to an ash. | |||

Unlike much other biochar or charcoal production the burning of the emitted gasses yields about 70% of the energy available from the wood for cooking and heating and also greatly improves the emissions profile of the gasses that are emitted. | Unlike much other biochar or charcoal production the burning of the emitted gasses yields about 70% of the energy available from the wood for cooking and heating and also greatly improves the emissions profile of the gasses that are emitted. | ||

The stove design was based upon a design made by Edward Revill at [http://www.soil-carbon-regeneration.co.uk/ Swansea Biochar] and developed with his assistance. | The stove design was based upon a design made by Edward Revill at [http://web.archive.org/web/20190121211846/http://www.soil-carbon-regeneration.co.uk:80/ Swansea Biochar] and developed with his assistance. | ||

== Forest biochar rocket stove 0-3 == | == Forest biochar rocket stove 0-3 == | ||

| Line 15: | Line 19: | ||

After finding the work of [http://donkey32.proboards.com/thread/511?page=24 Peterberg] where he extensively tested a rocket stove design that burns unattended for an hour or more and collecting materials a new design was developed and the stove build began. | After finding the work of [http://donkey32.proboards.com/thread/511?page=24 Peterberg] where he extensively tested a rocket stove design that burns unattended for an hour or more and collecting materials a new design was developed and the stove build began. | ||

Low quality [https://mediacru.sh/kqhT9G_BvVjn Mediacrush video] of first test firing - the stove performed well burning wood from broken pallets, with dried woodchip loaded into the retort to be made into biochar. The woodchip was not all converted into biochar - probably because the stove was only run for 1-2 hours. | Low quality [https://mediacru.sh/kqhT9G_BvVjn Mediacrush video] of first test firing - the stove performed well burning wood from broken pallets, with dried woodchip loaded into the retort to be made into biochar. The woodchip was not all converted into biochar - probably because the stove was only run for 1-2 hours. It was expected that longer runnning times of the stove would be necessary to avoid this. | ||

<gallery> | |||

File:Forest-biochar-rocket-secondary-air.jpeg|Secondary air feed: Back of firebox during build. | |||

File:Forest-stove-inside-firebox.jpg|Firebox: Inside firebox during fabrication. | |||

File:Forest-stove-riser-firebox.jpg|Riser and firebox: Riser welded to the firebox. | |||

</gallery> | |||

[https://mediacru.sh/U5V7tghr7vU_ Mediacrush video] of firebox with secondary air tube welded in place | [https://mediacru.sh/U5V7tghr7vU_ Mediacrush video] of firebox with secondary air tube welded in place | ||

| Line 35: | Line 33: | ||

[https://mediacru.sh/c05f40b328a8 Mediacrush photo gallery] of completed stove | [https://mediacru.sh/c05f40b328a8 Mediacrush photo gallery] of completed stove | ||

<gallery> | |||

File:Emptying_biochar_chamber.gif|Biochar being released. | |||

File:Forest_biochar_rocket_in_action.gif|Stove in action. | |||

File:forest_biochar_stove_temp.gif|temperature being read of running stove | |||

</gallery> | |||

=== Dimensions === | === Dimensions === | ||

The stove was built using [ | The stove was built using [[Media:ForestStove0-31dimensions.ods|these]] dimensioning calculations. | ||

The riser was made shorter as a hotplate is to be placed above the stove and it is necessary to have this at a height suitable for large cooking pans and so that the heat at the hotplate is maximised. | The riser was made shorter as a hotplate is to be placed above the stove and it is necessary to have this at a height suitable for large cooking pans and so that the heat at the hotplate is maximised. It is hoped that the chimney continuing up out of the hotplate will compensate for the [https://en.wikipedia.org/wiki/Chimney_draught#Chimney_draught_or_draft draught] lost due to the shorter riser. | ||

The port from the firebox into the riser has a cross section area (csa) close to 75% of the csa of the riser. | The port from the firebox into the riser has a cross section area (csa) close to 75% of the csa of the riser. | ||

The secondary air tube has a csa of 5% of the the riser csa. | The secondary air tube has a csa of 5% of the the riser csa. It also extends to cover the port by a similar amount. | ||

===[[ | === [[Wikipedia:CAD|CAD]] drawings === | ||

[ | [[File:ForestStove0-31.png|thumb|Forest biochar rocket stove stove 0-31]] | ||

.stl files will open with [[ | Again the model was made using the freeware [http://designspark.com/ Design Spark Mech] and exported as.stl files which were then imported into Art of Illusion for further manipulation. | ||

[[Media:ForestStove0-31.stl|STL CAD file for ForestStove 0-31]] | |||

.stl files will open with [[Wikipedia:FreeCAD|FreeCAD]] | |||

=== Cooking module === | === Cooking module === | ||

A module was made to fit onto the stove to enable it to be used for cooking. | A module was made to fit onto the stove to enable it to be used for cooking. This provided a hot oven, a warm oven/dehydrator, and a large surface for multiple pans. Over the winter of 2014-2015 the stove was regularly used to cook for around 30 people. It ran every day and was used for three meals a day. | ||

<gallery> | |||

File:Forest biochar rocket stove with cooking module.png | |||

File:Forest biochar rocket stove with cooking module 2.png | |||

File:Forest biochar rocket stove with cooking module side view.png | |||

</gallery> | |||

=== Appraisal === | === Appraisal === | ||

The stove with cooking module fitted works well with dry wood in the firebox and dry woodchip in the biochar chamber. | The stove with cooking module fitted works well with dry wood in the firebox and dry woodchip in the biochar chamber. The stove produces lots of heat and is a great space heater. The firebox emits plenty of heat that could be used more effectively (a bigger biochar production chamber? which should also insulate the firebox forcing more heat up the riser). | ||

The firebox was altered to give it a flat top to give extra cooking surfaces (and use more of the heat). | The firebox was altered to give it a flat top to give extra cooking surfaces (and use more of the heat). Unfortunately the hopper for loading the biochar is positioned over the part of the firebox which emits the most heat and stops this heat being re-purposed easily. | ||

Insulating the ovens may make them more effective but vents may be required so the temperature could be regulated. | Insulating the ovens may make them more effective but vents may be required so the temperature could be regulated. | ||

Often the stove was used with wet wood. | Often the stove was used with wet wood. This had to be chopped very small and often would only get to a good cooking temperature when woodchip had been added to the biochar chamber. | ||

== Forest biochar rocket stove 0-2 == | == Forest biochar rocket stove 0-2 == | ||

A newer design based upon a refined design developed by Ed Revill from [http://www.soil-carbon-regeneration.co.uk/ Swansea Biochar]. | A newer design based upon a refined design developed by Ed Revill from [http://web.archive.org/web/20190121211846/http://www.soil-carbon-regeneration.co.uk:80/ Swansea Biochar]. | ||

< | <gallery> | ||

File:BiocharRocketStove.JPG | |||

File:BiocharStoveDesign1.jpg | |||

File:BiocharStoveDesign2.jpg | |||

File:BiocharRocketStove2.JPG | |||

File:BiocharRocketStove3.JPG | |||

File:BiocharRocketStove4.JPG | |||

</gallery> | |||

The forest stove 0-2 will, as with Eds stove, use 6 inch stainless pipe for the heat riser, but will use 8 inch stainless pipe for the combustion chamber, allowing for more fuel to be burnt | The forest stove 0-2 will, as with Eds stove, use 6 inch stainless pipe for the heat riser, but will use 8 inch stainless pipe for the combustion chamber, allowing for more fuel to be burnt | ||

| Line 97: | Line 98: | ||

The filler hatch for the biochar production chamber will be moved from the front to one side (here the right) to make room for the fuel hopper. | The filler hatch for the biochar production chamber will be moved from the front to one side (here the right) to make room for the fuel hopper. | ||

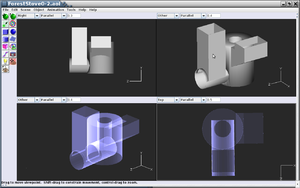

===[[ | === [[Wikipedia:CAD|CAD]] drawings === | ||

[ | [[File:ForestStove0-211.png|thumb|Forest biochar rocket stove stove 0-211.]] | ||

.stl files will open with [[ | This time it was found to be very difficult making some of the more complex shapes using [http://www.artofillusion.org/ Art of Illusion]<br>Some parts of the model were made using the freeware [http://designspark.com/ Design Spark Mech] and exported as.stl files which were then imported into Art of Illusion for further manipulation. | ||

[[Media:ForestStove0-211.stl|STL CAD file for ForestStove 0-211]] The model was slightly broken during export from Art of Illusion the hatch for filling the biochar chamber was placed away from the rest of the model | |||

.stl files will open with [[Wikipedia:FreeCAD|FreeCAD]] | |||

== Forest biochar rocket stove 0-1 == | == Forest biochar rocket stove 0-1 == | ||

| Line 110: | Line 112: | ||

See a [https://www.youtube.com/watch?v=4UQl-HR4iCk&list=PLWRnSEZz7QPaLuIipXvc33-juaQqJQQ9F video] of Ed explaining this stove. | See a [https://www.youtube.com/watch?v=4UQl-HR4iCk&list=PLWRnSEZz7QPaLuIipXvc33-juaQqJQQ9F video] of Ed explaining this stove. | ||

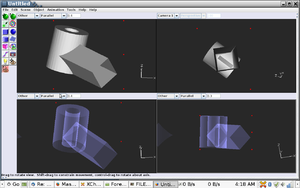

===[[ | === [[Wikipedia:CAD|CAD]] drawings === | ||

3D models were made using | |||

[ | 3D models were made using [http://www.artofillusion.org/ Art of Illusion] | ||

[ | |||

[ | * [[Media:ForestStoveRetort0-12.stl|STL CAD file for top of forest stove]] | ||

[ | * [[Media:Rocket Bottom View.png|Image of CAD drawing of bottom of stove]] | ||

* [[Media:Rocket top view.png|Image of CAD drawing of top of stove]] | |||

* [[Media:Rocket top view 2.png|Second image of CAD drawing of top of stove]] | |||

.stl files will open with [[ | .stl files will open with [[Wikipedia:FreeCAD|FreeCAD]] | ||

===Dimensions | === Dimensions === | ||

==== Bottom section ==== | |||

* Size fire tubes 8" square (A) | |||

* Thickness of plate for fire tubes 6mm | |||

* Thickness of vermiculite layers 3" on side 2" on top (B) | |||

Diameter of gas bottle | ==== Top section (retort) ==== | ||

Diameter of stainless tube | |||

Thickness of stainless tube 1.5mm or 2mm | * Diameter of gas bottle 14" (C) | ||

Use 304 or 316 stainless | * Diameter of stainless tube 6" (D) | ||

Total height of retort | * Thickness of stainless tube 1.5mm or 2mm | ||

* Use 304 or 316 stainless | |||

* Total height of retort 18" - 24" (18" should give better heat for cooking) | |||

{{Page data | |||

| keywords = rocket stove, biochar | |||

}} | |||

[[Category:Rocket stove]] | |||

[[Category:Biochar]] | [[Category:Biochar]] | ||

Latest revision as of 18:23, 18 June 2024

This stove was designed to provide a source of biochar for small scale growers while burning the gases given off form the char production to provide energy for space heating and cooking.

This is a rocket stove type design that uses small pieces of wood or other biomass as the insulation. The heat produced by burning wood in the rocket stove causes the wood/biomass insulation in the surrounding chamber (retort) to undergo pyrolysis. The gases produced by the pyrolysis are fed into the stove and burnt, As air does not flow through the retort the wood held within turns into biochar/charcoal rather than burning to an ash.

Unlike much other biochar or charcoal production the burning of the emitted gasses yields about 70% of the energy available from the wood for cooking and heating and also greatly improves the emissions profile of the gasses that are emitted.

The stove design was based upon a design made by Edward Revill at Swansea Biochar and developed with his assistance.

Forest biochar rocket stove 0-3[edit | edit source]

Following further conversations with Ed and research the stove design has evolved further to include a firebox which will reduce the amount of attention required to maintain a good fire.

After finding the work of Peterberg where he extensively tested a rocket stove design that burns unattended for an hour or more and collecting materials a new design was developed and the stove build began.

Low quality Mediacrush video of first test firing - the stove performed well burning wood from broken pallets, with dried woodchip loaded into the retort to be made into biochar. The woodchip was not all converted into biochar - probably because the stove was only run for 1-2 hours. It was expected that longer runnning times of the stove would be necessary to avoid this.

-

Secondary air feed: Back of firebox during build.

-

Firebox: Inside firebox during fabrication.

-

Riser and firebox: Riser welded to the firebox.

Mediacrush video of firebox with secondary air tube welded in place

Mediacrush video of firebox welded to riser inside the stove body

Mediacrush photo gallery of completed stove

-

Biochar being released.

-

Stove in action.

-

temperature being read of running stove

Dimensions[edit | edit source]

The stove was built using these dimensioning calculations.

The riser was made shorter as a hotplate is to be placed above the stove and it is necessary to have this at a height suitable for large cooking pans and so that the heat at the hotplate is maximised. It is hoped that the chimney continuing up out of the hotplate will compensate for the draught lost due to the shorter riser.

The port from the firebox into the riser has a cross section area (csa) close to 75% of the csa of the riser.

The secondary air tube has a csa of 5% of the the riser csa. It also extends to cover the port by a similar amount.

CAD drawings[edit | edit source]

Again the model was made using the freeware Design Spark Mech and exported as.stl files which were then imported into Art of Illusion for further manipulation.

STL CAD file for ForestStove 0-31

.stl files will open with FreeCAD

Cooking module[edit | edit source]

A module was made to fit onto the stove to enable it to be used for cooking. This provided a hot oven, a warm oven/dehydrator, and a large surface for multiple pans. Over the winter of 2014-2015 the stove was regularly used to cook for around 30 people. It ran every day and was used for three meals a day.

Appraisal[edit | edit source]

The stove with cooking module fitted works well with dry wood in the firebox and dry woodchip in the biochar chamber. The stove produces lots of heat and is a great space heater. The firebox emits plenty of heat that could be used more effectively (a bigger biochar production chamber? which should also insulate the firebox forcing more heat up the riser).

The firebox was altered to give it a flat top to give extra cooking surfaces (and use more of the heat). Unfortunately the hopper for loading the biochar is positioned over the part of the firebox which emits the most heat and stops this heat being re-purposed easily.

Insulating the ovens may make them more effective but vents may be required so the temperature could be regulated.

Often the stove was used with wet wood. This had to be chopped very small and often would only get to a good cooking temperature when woodchip had been added to the biochar chamber.

Forest biochar rocket stove 0-2[edit | edit source]

A newer design based upon a refined design developed by Ed Revill from Swansea Biochar.

The forest stove 0-2 will, as with Eds stove, use 6 inch stainless pipe for the heat riser, but will use 8 inch stainless pipe for the combustion chamber, allowing for more fuel to be burnt

The new fuel hopper that feeds wood into the combustion chamber will also differ being 8 inch square, vertically aligned and much taller allowing for larger pieces of wood to be loaded into the hopper reducing the amount of attention that the stove will need to stay alight.

The filler hatch for the biochar production chamber will be moved from the front to one side (here the right) to make room for the fuel hopper.

CAD drawings[edit | edit source]

This time it was found to be very difficult making some of the more complex shapes using Art of Illusion

Some parts of the model were made using the freeware Design Spark Mech and exported as.stl files which were then imported into Art of Illusion for further manipulation.

STL CAD file for ForestStove 0-211 The model was slightly broken during export from Art of Illusion the hatch for filling the biochar chamber was placed away from the rest of the model

.stl files will open with FreeCAD

Forest biochar rocket stove 0-1[edit | edit source]

See a video of Ed explaining this stove.

CAD drawings[edit | edit source]

3D models were made using Art of Illusion

- STL CAD file for top of forest stove

- Image of CAD drawing of bottom of stove

- Image of CAD drawing of top of stove

- Second image of CAD drawing of top of stove

.stl files will open with FreeCAD

Dimensions[edit | edit source]

Bottom section[edit | edit source]

- Size fire tubes 8" square (A)

- Thickness of plate for fire tubes 6mm

- Thickness of vermiculite layers 3" on side 2" on top (B)

Top section (retort)[edit | edit source]

- Diameter of gas bottle 14" (C)

- Diameter of stainless tube 6" (D)

- Thickness of stainless tube 1.5mm or 2mm

- Use 304 or 316 stainless

- Total height of retort 18" - 24" (18" should give better heat for cooking)