A tile leveling system to reduce tile lip when installing large format tiles. These types of systems are very common when installing larger tiles (which have a tendency to warp of otherwise not be level). The goal of the system is to be easy to use, effective, low cost, and fully editable. If needed, the entire system can be customized for an individuals needs by using the SCAD files inlinked down bellow.

Bill of Materials[edit | edit source]

- PLA plastic filament

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

- To use the SCAD files (not required for the average user) you will need to use the Belfry OpenScad Library (BOSL). This library can be found here [1]

Skills and knowledge needed[edit | edit source]

Basic tile installation [2]

Technical Specifications and Assembly Instructions[edit | edit source]

Printable STL and SCAD Files[edit | edit source]

All files are avaible at [3]

Print Instructions[edit | edit source]

For all printed components Material: PLA

Layer Height: 0.2mm

Shell Thickness: 1mm

Fill Density: 30%

Print Speed: 85 mm/s

Printing Temperature: 200 C

No supports necessary.

Total Printing Time: 2-3 hours

Assembly time: N/A (varies based on application)

Assembly Instructions[edit | edit source]

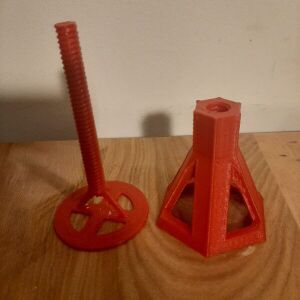

- When installing your tile, place the plastic bases in the mortar between two tiles.

- The thin circular base should extend underneath the tiles

- Once both tiles have been placed (and before the mortar has set).

- Take the plastic cap and tighten it onto the threaded base.

- While tightening double check that all tiles are level. Be careful not to over tighten.

- Once your mortar has dried:

- Unscrew the cap (you can reuse these)

- Break-off the upper portion of the base hammering the base as close the the surface of the tile as possible in the direction of the tile seam. This will break off the upper portion of the base. (The lower disk portion will stay underneath the tile)

Common Problems and Solutions[edit | edit source]

- No known issues

Cost savings[edit | edit source]

Break Down of Costs[edit | edit source]

(Assuming $20/kg of PLA)

- Base :$0.10

- Cap :$0.10

Total cost to Manufacture: $0.20

Comparable Costs[edit | edit source]

Commercially Available Tile Leveling System: ~$0.35 Savings: $0.10 (~ 66% reduction in cost) Because hundreds of these can be needed to install even a simple floor. this cost difference can quickly become significant.