Technical Guide for Tilapia Farming (CDI, 1998, 51 p.)

Tilapia[edit | edit source]

'Tilapia' are fish species that are fresh water cichlids but some species are described as being eurhyaline. a term which means that they can tolerate and adapt to different water salinity levels including, under certain conditions, sea water.

There are some 80 species of tilapia where almost all of them are of African origin although a few species come from the Israeli and Jordanian geographic regions. From all of these species, only a few tilapia species possess the characteristics required for interest in commercial fish fanning. It should be noted that the scientific classification confers to 'tilapia' several different species names, notably Sarotherodon and Oreochromis.

Tilapia is also identified under a number of different generic names; it can be called "carpe" in West Africa, "St Peter's Fish" in Israel, "bream" in Southern Africa, "mojarra" in Latin America and, of course, under many different local names.

The biology of many individual tilapia species is now well known and the interest in using these species for fish farming has led to considerable developments in recent decades.

The principal practical reasons for farming tilapia are:

- simple reproduction/breeding processes;

- rapid growth rate;

- good tolerance to high stocking densities and intensive rearing conditions;

- resistance to physical handling.

It is therefore a robust performer that reduces many of the general risks encountered in fish stock farming. Tilapia has also a very good reputation with consumers, usually available at a reasonable price which, combined with the high quality of its flesh, allows it to occupy a good place in most markets.

Notions of Tilapia rearing[edit | edit source]

Breeding[edit | edit source]

The reproduction of tilapia is best achieved in ponds, arenas or in 'hapas'(1), as described below but the basic principles that are used for breeding remain identical in all cases:

(1) A 'hapa' is a small cage that can be immersed in a pond or shore-line conditions

- Brood fish are stocked together and at the ratio of 3 females for 1 male:

- Stocking density may vary from 1 to 4 fish per m2.

Spawning occurs naturally when the female arrives at the stage of maturity; the female lay eggs in a nest that is built by the male (for Oreochromis sp.). The female lays the eggs in the nest where external fertilisation by the male ensues. The female then incubates the fertilised eggs in her mouth. The fry develop during this period of buccal incubation until the complete re-absorption of the yolk sac of the fry and, often, even later.

The occurrence of tilapia breeding is influenced mainly by water temperature where breeding activity will ensue at temperatures around and exceeding 22°C; below this temperature, the breeding process is inhibited. In practice, according to the geographical zone, a period of non-breeding or low reproductive activity will probably occur (even in tropical zones) due to the incidence of low cyclical temperatures (winter). Fry production needs to be planned according to these criteria.

- Where breeding is done in ponds, the parent brood fish will be left together for +/-40 days (up to a maximum of 2 months), before being harvested from the pond with large mesh nets, in order to capture the brood fish but to leave the fry in the pond.

- The fry will remain in the pond for another month so that they can be grown to a sufficient size to be harvested without damage (where the individual body weight should be >5 g.).

- Fry can also be harvested daily: A shallow net is usually used, allowing broodstock fish to escape underneath, while new-born fry, which swim on the surface of the water, will be caught.

- When breeding arenas are used, fry must be harvested daily, in order to avoid cannibalism (bigger fry acting as predators on the newborn).

- Following harvest, fry will be counted and reared thereafter in small tanks or ponds.

For all tilapia species, the male is bigger than the female and has higher production performances for farming (growth speed and food conversion ratio). Different methods can be used to obtain, theoretically, 100 % male populations in order to make best use of these characteristics.

In commercial fish fanning, the following are the principal techniques applied in order to obtain mono-sex populations:

· hormonal sex reversal of fry, · hybridisation through inter-species breeding · genetic manipulation.

The main advantage of working with mono-sex populations is to avoid the problems of uncontrolled over-breeding that can be problematic for good stock-control procedures.

It must also be recognised that efforts geared to the production of high quality; healthy fry are invariably rewarded by better growth and productivity for the adult fish.

Fingerling production[edit | edit source]

Fingerling production requires specific facilities that are adapted to this stage of farming and if controlled management of the production scenario is to be successful.

Fingerlings can be produced in ponds, concrete tanks (round, square or D-end) or floating cages. The main point, particularly if high rearing densities are to be applied, is that the feeds administered must be of high quality.

Moreover, if the possibility exists, fry and fingerlings will always benefit from a longer residence time, at low stocking densities, in a pond that has 'natural' feed production. Residual mortalities that occur at this stage are usually linked to the stocking density (too high) and the natural physical or genetic vigour of the fry in question.

On-growing - the production of marketable fish[edit | edit source]

The commercial size of fish varies according to local and international market demand and the price obtained per kg is usually a direct function of the individual size of the fish.

Globally, the market size for tilapia varies between 200 to 800 g.. Local markets often have outlets for a wide range of sizes while export markets require the production of larger fish because they are more likely to be sold as individual fillets of 100 to 140 g. (corresponding to a fish of 600-800 g.). It is important to remember that is always easier to produce smaller fish for economical and technical reasons but that the market is king.

For this stage of production, as for the others, different types of rearing can be used: extensive -semi-intensive - intensive and done in ponds, tanks, raceways or cages. These possibilities are summarised in the following table:

| Facilities | Extensive | Semi-intensive | Intensive |

|---|---|---|---|

| Earthen ponds | Yes | Yes | No |

| Tanks | No | Yes | Yes |

| Concrete ponds | No | Yes | Yes |

| Raceway | No | Yes | Yes |

| Cages | No | Yes | Yes |

Definition of the terms employed:

Extensive rearing: Growing fish in ponds of a surface area which can be more than 1 Ha, low density, no formulated feeds (pellets), but sometimes using edible by-products or stimulating natural feed production by applying organic or inorganic fertilisers. There is no aeration and a low water exchange. Production to forecast with this type of system can be estimated at 5 to 8 tonnes per hectare per year. Polyculture can be used to increase the overall production; polyculture is the rearing, in the same facilities, several different species.

Semi-intensive rearing: Growing fish in ponds or cages at low to medium densities (5-15 kg/m3), using supplementary feeds (formulated feeds or agro-industry by-products), a daily 10 to 20 % water exchange, aeration used sometimes and particularly at night.

Intensive Rearing; Growing fish at high stocking densities (20-120 kg/m3 for tilapia and more than 300 kg/m3 for catfish), use of high quality formulated feeds, high water exchange rates (e.g. 1 to 3 times per hour and more), and use of artificial aeration in most circumstances.

Technical characteristics of the facilities[edit | edit source]

The following information should serve to help the estimation of the technical value of the facilities described when visiting existing fish farms. For further details, it is necessary to refer to the appropriate technical handbooks (see Bibliography).

Earthen ponds[edit | edit source]

Earthen ponds are more commonly used in tropical fish farming and represent the oldest fish farming facility. A good pond will show the following characteristics:

- A well designed water supply but also easy drainage. This means a slight slope (0,5 %) of the pond floor from the water inlet to the drainage point.

- The drainage outlet (standpipe or monk) must be studied with care.

- Water inlet and outlet will be at opposite ends in order to ease water exchange within the pond.

- Good impermeability of the pond as a whole and strength/integrity of the pond's walls and edges.

- Access and possibility to work around the pond which must be accessible to vehicles (tractors/trucks & trailers etc.).

- Size of ponds must be adapted to the species but also be easy to manage. If the width exceeds 50 metres, it becomes difficult to pull nets for harvest (e.g. 3 to 4 men on each side are necessary to pull a 60 m. net) rendering the ponds impractical.

Concrete ponds[edit | edit source]

Concrete ponds are used for intensive fish farming; concrete walls/banks eliminate erosion due to currents caused by mechanical aeration, waves generated by the wind and fish activity (notably nesting behaviour). This type of pond is more expensive to build and, therefore, should be made profitable by a higher production per volume utilised. Conversely, the firmer walling reduces maintenance and re-building costs that will be necessary after a few years of operation,

This type of pond is smaller than earthen ponds and should not exceed 1,000 m2 surface area. The bottom can also be in concrete but for reasons of construction costs, only if the pond size does not exceed 200 m2. Brick or stone walls must have strong foundations and, if they are built with bricks or blocks, they must be plastered, in order to avoid the effects of erosion.

Raceways[edit | edit source]

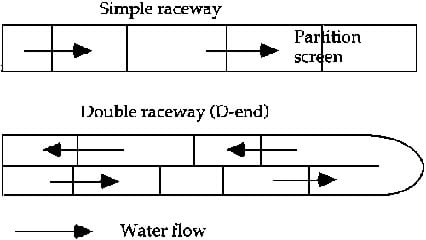

Raceways are concrete canals that can be partitioned with screens. This type of facility is often used for trout farming but is not as suitable for tilapia that prefers the calmer waters of a pond. One must note that is necessary to aerate the water along the entire length of a raceway because the oxygen can often be totally consumed by the fish that are sited at the beginning of the raceway. The complete drainage of a raceway is often difficult because different batches of fish are grown simultaneously in the different sections and the whole of the raceway must be completely empty of fish.

- Raceway, top view

Floating cages[edit | edit source]

There are many possibilities for obtaining floating cages for growing fish, from locally-made ones (usually cheaper but more fragile) to high technology cages (more expensive and more robust) which are usually used in exposed sites. The selection can only be made according to the overall practical considerations concerning the site, the production targets, and the project's economics.

While the optimal size for a tilapia cage is unknown, one should consider that the bigger the cage, the cheaper it costs in both material and equipment elements. Choice will be determined by considering the ease of management and the final production cost.

It appears that a cage of a dimension of 100 m2 is a good compromise. Concerning the depth of the nets, the. technical possibilities and maintenance expertise will determine the choice. If the net is deep, special diving equipment will be required for daily checking of the nets and eventual repairs. If the depth does not exceed 3 to 3,5 m., repairs & maintenance can be made through free diving.

Materials used for the floating structure.

Locally made cages[edit | edit source]

The floating structure of cages can be made out of metal or polyethylene floats, on top of which some walkways will be fixed, in order to obtain a square floating structure from which nets will be hung. The size of the cage will be adapted according to the material's strength and the physical constraints faced (waves, storms, and wind).

Industrial cages[edit | edit source]

With the development of salmon and other marine species farming, equipment manufacturers have developed a large range of cages made from different materials and components. High-density polyethylene is often used for the retaining structure, this material offering the advantages of strength and longevity. Cage structures can be square or circular and of many different sizes. Circular cages are invariably cheaper to buy (relation between diameter and surface) while square cages are easy to assemble and facilitate work and fish handling tasks.

Polyethylene Cubes[edit | edit source]

Finally, some cages are made from assembled polyethylene cubes, easy to mount and adaptable to different sizes and forms.

Nets[edit | edit source]

Nets are the subject of very careful selection. Their quality must be beyond reproach since the security of the fish stocks depends largely on the net strength. Mesh size must be adapted to the fish size and. must not allow the fish to trap itself by the gills. On the other hand, small size mesh is subject to fouling which restricts the water flow through the cage. Nets are sold by weight and, therefore, those with a small size mesh are more expensive.

Large farms will also invest in net-washing equipment, which imposes the need to have cages with adequate net-removal facilities.

Predation[edit | edit source]

Predation risks must also be studied, where these can be birds or aquatic animals. Dependent on the predator species, a physical barrier may need to be installed to avoid contact with the 'rearing' net. Strong nylon nets can be fixed at a distance of about 50 cm. from the rearing net. For birds, light nets (large mesh) are stretched above the water surface.

Storms[edit | edit source]

Climatic conditions causing floods are seen as the most dangerous. Sometimes, atmospheric conditions can create additional serious problems; e.g. a rapid drop of atmospheric pressure lowers the water surface tension and therefore causes oxygen depletion in the water. This phenomenon can lead to substantial fish losses. Fortunately, tilapia is particularly resistant to these conditions and, providing that rearing densities allow it, the fish will be able to take oxygen from the water surface (richer in 02) during a few hours.

Theft[edit | edit source]

This problem exists in almost every fish farm in the world and in-depth reviews of the security aspects of individual farms must be considered case by case.

Fish processing[edit | edit source]

Only when the fish has reached its commercial size does it obtain its full commercial value (prior to this stage it has only a relative & calculated stock value). Harvesting, processing and packaging are therefore important and critical operations, which represent the source of income and profit for the project explaining why care and attention must be paid to these final parts of the process.

Harvest and transport[edit | edit source]

In tropical regions, any fish handling is tricky due to the high ambient temperatures. When the fish is harvested, its body temperature is the same as the water temperature (often >25°C.) and the air temperature is usually the same or higher. It is therefore very important to chill the fish as quickly as possible and to maintain it at a low temperature. It is recommended that, following harvesting, the fish are stocked on ice for immediate transportation to the processing plant which, ideally, will be as close as possible to the fish farm on-growing installations).

Ideally the processing factory would be air conditioned in order to keep the ambient temperature below 15°C. The size and equipping of the factory will be adapted to both the products envisaged and the production volumes e.g. fresh or frozen products, whole fish, fish fillets. It must obviously be capable of accepting and storing the harvest volumes anticipated.

If fillets are to be made, the quantities to be processed will determine the degree of automation allowed. When the volume offish to be filleted becomes important (e.g. >1 ton per day), the installation of a complete filleting line can be considered. This consists of

- a fish gutter and cleaner

- a drum-based de-scaling machine

- a de-heading machine,

- a filleting machine,

- a skinning machine

- A fillet washing system.

A fillet-grading machine (separation by weight) can also be installed using plate or tunnel freezers if the product is to be deep-frozen. Different machines are available on the market and selection can only be based on the production and technical specifications of the products to be made.

Any packing system will also be studied in line with the nature of the finished products. Such a processing line increases the quality and added value of the products and could allow the project to target export markets. However, processing and packing usually represent an investment of more than 250.000 ECU. Storage installations (cold rooms and freezers) are also very important in the concept of a factory whose design must not allow any break in the cold chain.

Additionally, the acceptance of HACCP5 principles as the modus operandi of food processing requires expertise and rigour in the management of food production. The employment of technical staff uniquely for quality control and product follow-up is essential.

5 Hazard Analysis and Critical Control Points: The Food and Agricultural Organisation of the United Nations is able to provide complete documentation for application of these techniques

Yields and losses to be forecast on tilapia filleting[edit | edit source]

The yield of the gutting operation varies between 88 to 92 %. In other words, 8 to 12 % of the body weight of the fish constitutes the offal (for 0. niloticus). This is obviously an important element to include in the calculation of production costs.

Variability in the yield

Filleting yields for tilapia is relatively low. For skin-on fillets, a 40 to 42 % yield can be obtained. For skin-off fillets, some 32% can be achieved if the filleting is done by hand (only 30% if a machine does the filleting). Once again, yields are variable following fish size and species.

Freezing can, if done before packing, generate a small loss (1 to 2 % in a blast freezer system). The freezing process must be done as quickly as possible and the frozen material must be packed before or just after freezing (according to the system), in order to avoid important dehydration losses.

The activities of processing and packaging, despite being directly linked to the fish farming activity, need a complete and specific study and presentation for investment decisions.

Ideas about fish farming management[edit | edit source]

Good management is essential to have a successful project and the conditions and constraints are similar to the livestock agricultural sector.

Planning of production programmes[edit | edit source]

The breeding periods must be identified in addition to the number of fry required, in order to start and reach the final production targets (calculations should include an allowance for mortalities and other sources of loss). A good forecast of realistically obtainable growth rates and knowledge of the facilities available will aid the accuracy of the production targets.

Potential project promoters must be careful when using theoretical projections which may only be valid in a different context and not necessarily transferable to the site under assessment. It is always advisable to adopt a prudent and conservative approach by allowing adequate security margins on the production forecasts.

Stocking[edit | edit source]

Before stocking a pond or a cage, the number of fish, the average individual weight and the total biomass of population must be known. Initial stock control followed by regular controls will allow reliable projections and a professional follow up.

Stock Measurements and follow up[edit | edit source]

Regular follow up of stock populations, their evolution and growth, is essential. These controls will be done at least monthly and sometimes twice a month for certain batches. These controls will also account for feed consumption and feed conversion ratios. Data will then be analysed and compared to general reference standards. Options for rearing can then be decided for the following time period (e.g. increase/decrease of feeding rates, grading, harvest, etc.). Every fish batch needs to be followed individually. For those farms with adequate computer facilities (PC), specific stock management programmes exist which are very useful for eliminating paperwork and providing up-to-date information on stock performance.

Optimal use of Growing Facilities[edit | edit source]

Based on productivity values, expressed in weight gain (grams) per unit of facility volume (or surface) (expressed in m3 or m2) and per day, production standards can be established. Production objectives will take into account some additional factors such as the time necessary for maintenance (where tanks/ponds cannot be used for growing), grading (where growth is lost due to stress), mortality rates, etc.. In fact, any factor that has a direct effect on the growth obtained within a given production unit.

The principle objective is to keep the farm's facilities at an optimal level of use, accompanied by the highest daily productivity, during the whole of the year in order to obtain the best annual production possible.

Some criteria used for economic projections[edit | edit source]

Some general parameters used for economic assessment will be presented in this section and which can be considered as indicators of the potential for commercial fish farming within the context of preliminary project study.

Investments[edit | edit source]

Each project, dependent on the physical terrain, its accessibility, slope and vegetal cover etc., needs to be studied in detail for assessing structural capital investment. However, on the basis of our experience in the field, the following are some guidelines used to evaluate the investments required for tilapia farming projects.

In 1995, in Gabon, a study of a fish-farming project (300 tonnes per annum) with a small processing factory, vehicles and buildings, indicated an investment of about 1.000.000 ECU or 3.333 ECU/ton of fish produced.

In 1995, in Southern Africa, a fish farm of 2,000 tons production potential (in cages), with a processing factory, equipped with a filleting line and meeting European hygiene standards, had an investment value of 3,000,000 ECU or 1.500 ECU/ton.

Bigger projects benefit from the economy of scale and give a lower investment figure per ton produced. One should also note that specific construction items are highly variable in value between individual countries and that extreme care must be taken when cross-referencing to similar projects.

Also, cage culture, even if it represents a lower initial capital investment, will have to be depreciated (amortised) over a shorter period (5-6 years) than either ponds (20 years) or concrete structures (15-20 years).

It is not recommended to foresee the construction of a fish farm for a production inferior to 300 tonnes per year, representing an investment of about 1,000,000 ECU (with processing plant). Below this production level, the financial returns are too low and it is difficult to justify the construction and operation of a processing plant.

Production costs[edit | edit source]

Following the market study for the fish concerned by the project, the costs of production give the best indication of the feasibility and hence the profitability of the potential venture.

Fish feeds[edit | edit source]

Feeds, in a commercial fish farm, represent the most important single item in the costs of production. It usually corresponds to at least 50% of the global production cost and can reach as much as 60-70 %.

On the other hand, feed prices range between 0,32 to 0,50 US$/Kg (1995) in the developing countries where it is available, price changes being dependent on the availability of local components and the value of imported items (usually quoted in US$ prices). While recognising that the feed conversion ratio of tilapia is variable, a value of 2 can be used for the purposes of calculation, which brings the feed cost to between 0,64 and 1,00 US$ for 1 Kg offish produced.

Labour[edit | edit source]

In developing countries, this item should represent between 10 to 12 % of the global production cost. Sometimes, one must allow for the presence of an experienced expatriate technician or manager for a 2-3 year period; this item will obviously affect significantly the personnel costs.

Depreciation[edit | edit source]

Depreciation of both capital investments should not exceed 15% and the total is usually around 12% of the total production cost.

Overheads[edit | edit source]

This item comprises all consumable goods (i.e.. chemicals, small equipment, staff obligations etc.), diverse operating expenses (such as bank charges, taxes, telephone etc.) and other administrative costs. These items, within the 'Overheads' label should represent about 10 % of total production costs.

Repairs & maintenance[edit | edit source]

These costs should be a maximum of 5 % of production costs.

Financial projections[edit | edit source]

Two factors (which are inter-connected) have to be considered:

- Fish farming, as for nearly all agricultural activities, does not generate immediate sales on the day after starting the business. According to the species and the time that it takes to obtain the market-size fish, the venture will have to invest and operate without any income for a certain period. In the case of tilapia, dependent on the time required for construction and equipping the project and then reaching the commercial size of the fish, a period of 18 to 24 months of self-sufficiency will be needed and must be allowed for.

- The second point concerns the building up of live stock fish. The 'permanent or working stock'6 required represents about 50 % of the yearly production of the farm i.e. a fish farm that produces 200 tonnes of fish per annum needs, at the beginning of the year, a 'permanent stock' of about 100 tonnes of live fish of different sizes. This should remain the same at the end of each year if the farm is in a state of steady-state operation.

The permanent stock is the fish stock level that is carried over each year and forms the basis of the production stock for the year to come.

This stock must be financed at the beginning of the activity and will eventually be recovered when the farm closes down or if the venture is sold. Building up such a stock of fish must also be considered as the establishment of an important company asset.

These two parameters have to be studied and integrated correctly within the financial projections where it is worth contacting a local accountant as to the rules concerning stock valuation and the means of incorporating 'start-up' expenses within the overall financial structure of the company.