- untested

- not ergonomic

- upper supports weak

- too much mass in unnecessary locations- bulkiness

- yet not sturdy enough for use

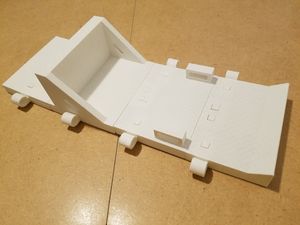

Title of the device or system[edit | edit source]

Project developed by Ickesler

Abstract[edit | edit source]

Snowshoes help to maneuver through a snowy terrain by foot. They allow someone to walk on top of the snow as opposed to sinking down into the snow with every step. This allows for easier movement across powdered snow, without taking a lot of effort to pull your foot out of knee deep snow with every step. This snowshoe design allows someone to print a snowshoe on a 3D printer that utilizes a 1/2" tubing for the outer support, and twine for the straps. All of these supplies are fairly cheap and easy to transport.

Bill of Materials[edit | edit source]

Printed parts from YouMagine

- Snowshoe Part 1

- Snowshoe Part 2

- Snowshoe Part 3

- Snowshoe Part 4

- Fastener Insert

- Tube Insert

Other Parts:

- 1/2" PVC piping with end covers

- twine or straps

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

Skills and knowledge needed[edit | edit source]

- 3D Printing

Technical Specifications and Assembly Instructions[edit | edit source]

- Each of the Snowshoe parts fit together. The parts fit in numberical order.

- The tube inserts go in the slots on the side of the snowshoe.

- The rectangular inserts get pressed into the sqiare holes, securing everything in place.

Print Time Estimates:

- Snowshoe Part 1

- 5 hours 22 minutes

- Snowshoe Part 2

- 6 hours 4 minutes

- Snowshoe Part 3

- 9 hours 55 minutes

- Snowshoe Part 4

- 4 hours 45 minutes

- Tube Insert

- 23 minutes each

- Rectangular Insert

- 5 minutes each

Common Problems and Solutions[edit | edit source]

- Make sure to remove all support material or the pieces might not fit together.

Cost savings[edit | edit source]

Printing Cost: $13.34

Commercial equivalent: L.L. Bean Snowshoes $109

Cost Savings: $95.66 (87.76%)