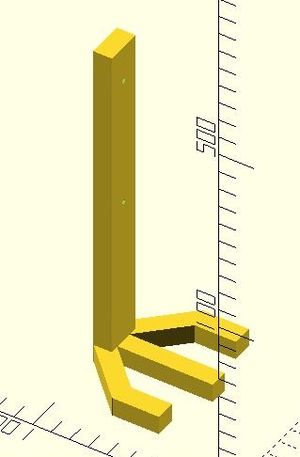

This project is made for people who wish to pick unreachable fruit from trees. Forcing fruit out of a tree causes it to bruise and spoil quicker than that that is picked from with care. The fruit picker is printed in two parts. It uses a regular 2 liter soda bottle along with five screws to assemble. It does also require an old broom handle or piece of pipe to use as a handle. This is a cheaper alternative to what is already on the market and is more universal in the handles it can use.

Bill of Materials[edit | edit source]

CAD Files

Extra Parts

- 1/8" x 3/8" sheet metal screw (x2)

- 1/4" x 1-1/4" machine screw (x3)

Tools needed for fabrication[edit | edit source]

- 3D printer

- Equivalent screw drivers to match screws used

Skills and knowledge needed[edit | edit source]

- There is no special skills needed to make this tool.

Technical Specifications[edit | edit source]

- If any changes to the design want to be done, open the SCAD file and adjust the parameters.

- Slicing instructions:

- Fill % = 50

- Speed = 70 mm/sec

- Layer Height =.15 mm

- No support Needed

- Print time with above settings will be about 3 hours per part

Assembly Instructions[edit | edit source]

- Cut bottom off of 2 liter bottle at desired location

- Screw sheet metal screws through bottle so they line up with holes in poth 3D printed parts

- Evenly screw last three screws to fix to handle

Cost savings[edit | edit source]

Cost of creating this hammer

*Filament needed: 82 grams @ $22.98/kg = $1.88 *Hardware needed: 5 screws @ $1.50 *At a total cost of $3.38

Commercial Equivalents

*Equivalent: $10.69

Gallery[edit | edit source]

-

Fork SCAD

-

Stem SCAD

References[edit | edit source]