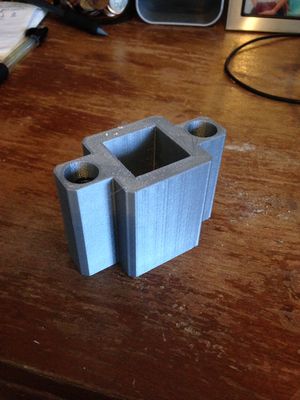

With two small printed parts and two springs, my corn crusher can do what its name implies: crush corn. This device is supposed to replace the mortar & pestle by making it easier and less labor-intensive to grind corn into flour. The contributes to solving OSAT Goal 2: zero hunger

Bill of Materials[edit | edit source]

- Openscad files and STL's on Thingiverse

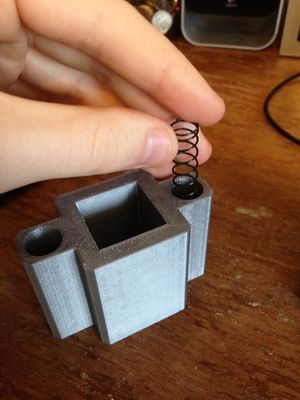

- 2 small springs to fit into the circular holes of the housing. Diameter should be no greater than 12 mm. The uncompressed length should not be larger than 35 mm.

- 1 3D printed housing

- 1 3D printed pedal

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

Skills and knowledge needed[edit | edit source]

- N/A

Technical Specifications and Assembly Instructions[edit | edit source]

Print settings for both pedal and housing:

- Layer Height: 0.2 mm

- Shell Thickness: 1.0 mm

- Bottom-Top thickness: 0.6mm

- Fill Density 20%

- Print Speed: 100 mm/s

- Print Temperature (PLA): 200 C

- Flow: 100%

- Print the housing.

- Print the pedal (Note: there is corn dust on the pedal from previous use).

- Insert the springs into the housing.

- Insert corn into the middle square hole of the housing. Insert the pedal into the housing. Begin crushing by placing the device in both of your palms and squeezing the pedal into the housing. Alternatively, place the crusher on the ground and use your feet to push the pedal down.

Common Problems and Solutions[edit | edit source]

- In some underdeveloped nations, it is common to spend an entire day grinding grain with a mortar & pestle. This device can grind corn although I'm not sure if it is quicker than a mortar & pestle. One clear advantage is that this corn crusher can be operated by the hands or by stomping on the pedal with your feet. If your hands get tired, you can just use your feet. While you could grind more corn by making the hole bigger, the applied crushing pressure on each kernel of corn would go down since the area is increased. If a future designer does increase the hole size, it is not advised to increase the area by much.

Cost savings[edit | edit source]

- Approximate cost for housing: $0.30

- Approximate cost for pedal: $0.20

- Approximate total cost: $0.50

- A primitive mortar & pestle would be made out of stone or wood; it would not be bought. Rather than money being saved, it would take less time to grind corn.

References[edit | edit source]