Using a closed loop belt has significant advantages over an open loop belt.

- Carriage assembly can be much simpler.

- The printer can be used for other purposes involving rotatory motion, instead of linear, such as centrifuge, tensile testing, etc.

The proposed system uses ninjaflex to print a belt extension piece which will enable the printer to work in 2 modes: 3D printer mode and free rotation mode.

- This system converts an open loop to a closed loop.

Materials Needed[edit | edit source]

- Ninjaflex or similar flexible filament.

Items to 3D Print[edit | edit source]

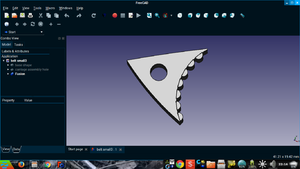

- A belt extension piece of ninjaflex to be glued to the belt.

- Spacer for carriage

Thingiverse link http://web.archive.org/web/20160116152312/http://www.thingiverse.com/thing:1193826/

Instructions[edit | edit source]

- Print the belt extension piece of ninjaflex with high accuracy and 100% infill.

- Firmly glue one side of the belt to the belt extension piece.

- Pull the belt tight around the pulleys.

- Clamp the belt and the belt extension piece together and glue them.

- Inset spacer between the belt extension piece and the carriage.

- Fix position using a bolt.

Notes[edit | edit source]

Make sure to leave a little or no space after the teeth of the belt while sticking to the inside of the belt extension piece, i.e make sure that a tooth just sticks out from the belt. This will ensure better mating with the pulley.

Disadvantages of this method are:

- The belt extension piece requires high resolution which is expensive to manufacture.

- A regular 3d printed piece will not mate perfectly and might slip.

- Gluing the belt means that it cannot be reused for printing. A new belt would be required every time the belt is removed.

- Theoretically, the belt cannot be perfect, the trick is to make sure that the disadvantages do the least harm

Future work and improvements[edit | edit source]

- A lot of changes have to be made to the athena to make sure that the belt can complete a full rotation and act as closed loop.

- A smaller radius on the belt extension piece would ensure better mating with the pulley, however, printing a component that small did not show positive results due to printer resolution.

- A belt of lower width, or a wider pulley will enable the use of a clamp in the belt extension piece. This would eliminate the need to glue the belt.

- Low tension applications should not have any problems with this system.