This adjustable ankle support prosthetic has been designed to be used as an appropriate technology, due to being composed of 4 3D-printed parts and a few pins (the pins, of which, can be whatever is available to the user). This has been designed to substitute prosthetics or braces that are unavailable to the individuals specified.

Bill of Materials[edit | edit source]

SCAD files:

- File:777 Ankle Support OSAT Part C.scad

- File:777 Ankle Support OSAT Part D.scad

- File:777 Ankle Support OSAT Part A.scad

- File:777 Ankle Support OSAT Part B.scad

- Preferred filament (PLA Intended)

- 2 Metal / Plastic / Wood pins, ~1.6 mm diameter, one of them ~8 mm length, the other ~16 mm length

- Elastic Cloth, Shoelaces, or small twine

Tools needed for fabrication[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

- Tools to smooth and refine prints (deburring tool, sandpaper)

Skills and knowledge needed[edit | edit source]

- Knowledge of using 3D Printers

Technical Specifications and Assembly Instructions[edit | edit source]

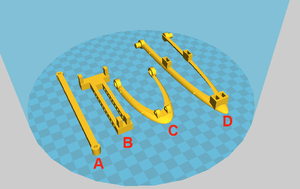

- Mount and insert the pegs on the top of part 'B' into the holes on the top of part 'D'

- Place one of the holes of part 'A' in between hinge assembly on bottom of part 'C'; insert a pin to stabilize

- place large outer disks of part 'D' into the shafts of part 'C', ensuring the top of the parts shown in the image remain on the same side

- Place other hole of part 'A' into one of the holes in the center of part 'B'.

- Place onto user and insert shoelaces through small holes across parts 'C' and 'D'; tie shoelaces to fit user.

- 4 hour print total, assuming 60 mm/s print speed and 40% infill.

- ~20 minutes to assemble

Common Problems and Solutions[edit | edit source]

- Slots of parts 'B' and 'D' may not fit well; sand and smooth parts as needed.

Cost savings[edit | edit source]

- ~ 80 grams to print at defined settings. Assuming $30/kg of filament, as well as the purchase of pins here, cost will be ~$6.20 for entire product.

- $50 ankle brace -- http://www.ultraankle.com/ultra-zoom?gclid=COXm8u2jzMkCFQoKaQodFwQEpQ

- Saved $43.8, or 87%