With a modular setup, this device can be used as multiple tools in one. Main applications could be for people from third world countries where there is minimal automation. A shovel helper grip attachment could save a lot of effort by transferring some of the load from the user's back to the well gripped other hand. This in-turn results into lesser fatigue and more productivity.

Also, the Leaf Claws attachment can function as a big sized leaf collector hand or as even a shovel for damp yards. These type of attachments could also be used to reach certain areas (eg: for maintenance purposes in sanitation) where use of bare hands could have caused infections.

Bill of Materials

- 3 bolts: 5/16 inch diameter with approx 5 cm length: 38 cents x 3 = USD 1.14

- 3 Nuts that fit into those bolts: 21 cents x 3 = USD 0.63

- Hair band / Rubber band: Free?

- PLA filament: Approx 50 x 3 grams = USD 3.2

The STL files and FreeCAD files for the parts can be found here:

Tools needed

- MOST Delta RepRap or similar RepRap 3-D printer

Skills and knowledge needed

- Knowledge of FreeCAD and Cura

Technical Specifications and Assembly Instructions

To Assemble:

- Download the part files provided above in the bill of materials

- Convert stl files to gcode using software like Cura

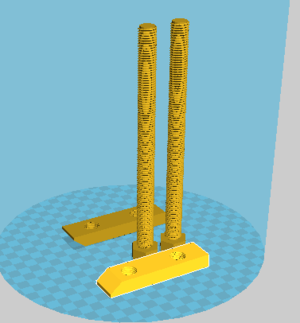

- Print all of the Parts

- Attach a hair band / rubber band with the handle arm to make it a comfortable grip on the user's wrist

- Connect the interlocking jaws of whichever tool you want to use

- Secure with nut and bolt

Time:

- Total print time estimate: 5 hours

- Total assembly time estimate: 3 minutes

Common Problems and Solutions

- One must be careful of your printer radius and calibration as a couple of those parts only just fit into my Delta: check how thw first couple of layers print and shrink the models if needed (all be same amount)

- Sticking to the bed could be a common problem in case of such large prints: Use high quantities of washable glue on bed before printing

Cost savings

- Cost Estimate: USD 5 for two tools

- Equivalent products in market cost: USD 33 (Backsaver grip: USD 13 and Leaf claw: USD 20)

- Net savings achieved: USD 28

References

- The sources of information (e.g. engineering handbooks, journal articles, government documents, webpages, books, magazine articles etc.). References should use the and <references />tags and can be in any format but should include all the information necessary for someone else to find the same information you did. For example:[1]

- ↑ web page: Department of Energy (DOE) Landscaping and Energy Efficiency, DOE/GO-10095 (1995) Available: http://web.archive.org/web/20021201231338/http://www.eren.doe.gov:80/erec/factsheets/landscape.html