Title of the device or system[edit | edit source]

Project developed by Benjamin Joseph Btjoseph (talk) 16:57, 5 December 2018 (PST)

Abstract[edit | edit source]

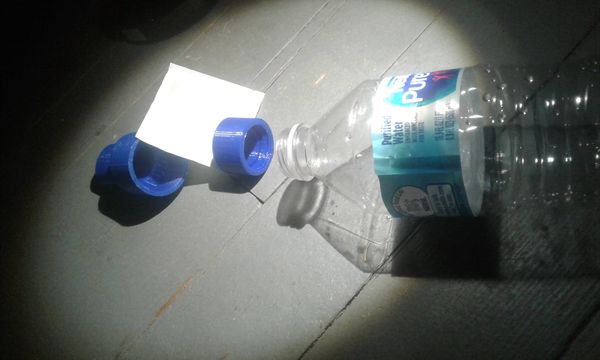

Many developing third-world countries have a steady or increasing need for clean drinking water. Many solutions for achieving clean drinking water already exist, but require expensive manufacturing equipment outside the area where there is a need, and then incur shipping charges to ship them to the target location. 3D printing technologies allow rapid manufacture of humanitarian-aid devices such as water purification tools. This printable design requires some filament (preferable ABS), a tea bag, and activated carbon to create. This allows the user to drink filtered water on-demand from and standard plastic water or pop bottle.

Bill of Materials[edit | edit source]

- One bag holder: [STL] https://www.dropbox.com/s/m304isdsx3zttvk/bagHolder.stl?dl=0 [OpenSCAD] https://www.dropbox.com/s/8o9cin6t8afvpzx/bagHolder.scad?dl=0

- One bottle cap: [STL] https://www.dropbox.com/s/newoc354qbt4e34/bottle_cap.stl?dl=0 [OpenSCAD] https://www.dropbox.com/s/vygh1cng4045tv7/bottleCap.scad?dl=0( Bottle cap also required thread component: https://www.dropbox.com/s/xcsaov23rt63dbe/Thread_Library.scad?dl=0)

- One tea bag.

- activated carbon (about a teaspoon).

Costs[edit | edit source]

- The activated carbon was obtained by cutting open a $6 Breta water filter (if bought in a six pack for $24) from Walmart. the carbon from one filter was able to fill 12 tea bags, making the carbon cost per bag $0.50. Activated carbon may likely be found cheaper than by using this method.

- Tea bags are available from Walmart in 100-count boxes for $3.50, yielding a unit price of $0.04 if rounded up.

- Cura estimates both parts will cost $0.51 to print.

Total cost: $0.50 + $0.04 + $0.51 = $1.05

The cheapest equivalent water bottle with an internal filter costs $10. This is a cost savings of just under 90%.

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer.

- No other tools!

Technical Specifications and Assembly Instructions[edit | edit source]

-

Print bottle cap at .2mm layer height or less, with the threads at the top, without supports. Support material clogs up the threads, creating unnecessary cleanup work. Estimated print time at 70mm/s: 22 minutes.

-

Print the tea bag holder as shown at .3mm layer height. Estimated print time at 70mm/s: 42 minutes.

-

Cut open a teabag at an edge and add one teaspoon activated carbon.

-

Stuff tea bag with carbon into the large end of the bag holder.

-

Screw cap onto bottle threads.

-

Fully seat the cap into the tea bag holder.

Benefited Internet Communities[edit | edit source]

References[edit | edit source]

Primal Survivor.net Available: https://www.primalsurvivor.net/ways-to-purify-water-survival/