Sliver plating standard operation procedure.[1] Silver metal plating has long been used for conductive coating, decoration and anti-corrosive coating and thus widely used in electronics, optics and furniture industry. Electro-deposition of silver is often involved of using high toxic cyanide solutions hence highly dangerous. Electroless deposition avoid of using such toxic solutions and is clean and energy saving. This is an improved method for electroless-deposition of silver.

Solution preparation[edit | edit source]

Ag Solution[edit | edit source]

- 0g silver nitrade diluted in 50.0ml DI water

- 5g NaOH diluted in 50.0ml DI water, let it cool to room temperature

Carefully drop 25%-28% ammonia hydroxide solution to silver nitrade solution until all the precipitants just disappear to give a transparent solution, stir 1 min. Add 20.0ml ammonia hydroxide solution, dilute to 800ml.

Reduction solution[edit | edit source]

- 0g three citric acid ammonium deluted in 50.0ml DI water, let's call this solution reduction #1

- 0g Sucrose deluted in 100.0ml DI water, heat the solution to boil for 5min, let it cool to room temperature, add 10ml ethanol, let's call this solution reduction #2

Pre-process solution[edit | edit source]

- 1g SnCl2 deluted in 800ml DI water

Operation procedure[edit | edit source]

- DI water wash the glass surface, then emerge the whole glass into the pre-process SnCl2 solution for a whole night.

- Wash the glass surface with DI water, then Ag solution:reduction #1 = 30:1(v/v) spread the mixed solution over the glass surface, use a horizontal meter to keep balance. The solution is kept on the surface for 30min, during this time, small silver grains are forming and deposited onto the surface, but they are not well developed and very fragile at this moment.

- Carefully dump the mixed solution, take Ag solution: reduction #2 solution = 10:1(v/v) and gradually spread over the glass surface, a uniform shinny silver layer will form.

- If the layer is not very thick(partial transparent), repeat 3 until desired thickness is achieved.

- Carefully dump the solution and wash the glass using DI water, make sure not scratching the glass surface at this moment. After washing, put the glass on a hot plate for 5 min at 80oC to consolidate the loosing silver layer.

Result and Conclusion[edit | edit source]

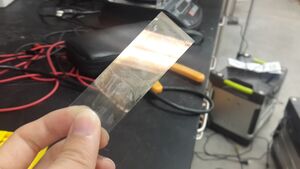

The measured resistivity is about 0.0036Ω/inch, this is considered to be good enough for electrical purpose. Formed silver layer has some resistance to external force, but not strong enough to survive harsh scratching and pressing. For open-source equipment development this is good, fast and possibly the cheapest way to produce a high conductive layer.

-

SliverPlating Glass

-

SliverPlating Glass 2

See also[edit | edit source]

References[edit | edit source]

- ↑ Schlesinger, Mordechay, and Milan Paunovic, eds. Modern Electroplating. 5th ed. The Electrochemical Society Series 52. Hoboken, NJ: Wiley, 2010.