This page details the journey that Team Pelican took to design a solar powered fan system for Potawot Community Health Garden.

Abstract[edit | edit source]

Our mission was to design a solar powered fan system for the Potawot Community Garden, part of the United Indian Health Services. We evaluated project criteria and put together a comprehensive literature review before beginning our design process. After researching about greenhouses, solar panels and fans, we began to brainstorm prototypes detailing the fan placement, where to put the panel, and how the wiring would look for a direct connection, and with a battery. After reaching out to an expert, we finalized our design and sent away for parts. As parts arrived one by one, the team began construction on the mounting box for the fan, and installed both the fan and shutter on the greenhouse. The costs of our project are also itemized below. At the end of this project, our solar panels had still not arrived so unfortunately, no testing was conducted. We are proud of the work we accomplished and it is our hope that this project can be applied to other greenhouses that wish to lower their carbon footprint and save some money on electricity.

Background[edit | edit source]

United Indian Health Services (UIHS) started in 1968 as Native Activism was just beginning, this was due to the Civil Rights movement at the time.[1] UIHS officially became a non-profit organization in 1970 and they started offering the only on-site health services they could: dental health services. They eventually were able to expand their mission to nearly every large city within Humboldt County and were able to cover a wide variety of health services including medical, behavioral health, pharmacy, a community nutrition program, Potawot Community Garden, as well as vision services.[1] A direct quote from their website about their belief of the importance of health is: "United Indian Health Services believes that the health of the community is only as strong as the mind, body, and spirit of each individual within it."[1] The Community Nutrition Program (CNP) and the Potawot Community Garden both were started in 1999 in an effort to help the surrounding community eat fresher and healthier.[1] The Potawot Community Garden is a Certified Farmers Market and provides nutritious food to the surrounding UIHS clients suffering from food insecurity.[1] The garden also donates thousands of pounds of produce to surrounding food banks, tribal community and youth events, as well as cultural activities annually. Potawot Health Village currently has four greenhouses where they grow cherry tomatoes, summer squash, beets, carrots, cucumbers, sweet and spicy peppers, sugar snap peas, quick pick herbs and are also home to a number of fruit trees. In order to protect their crops from mildew and other climate-related problems, two of the greenhouses are outfitted with electric fans as well as one portable fan which is used during the summer. Their ultimate goal is to become more resilient, and as close to 100% self-sufficient as possible. Having a low to zero carbon footprint is important to Potawot for themselves and inspiring other community gardens to do the same. ENGR 305 is an Appropriate Technology Engineering taught by Lonny Grafman at Cal Poly Humboldt and discusses appropriate technology and the thought processes that go into innovating those technologies. Lonny directed groups of students, including Team Pelican, formed by Rebecca Asbury, Chris Lo Greco, Ines Morales, and Foster Smith to pick a local project that focused on using renewable energy sources to help the community.

Problem statement[edit | edit source]

The objective of this project is to design and implement a solar-powered fan system for one of the greenhouses at the Potawot Health Village.

Project evaluation criteria[edit | edit source]

For the solar powered greenhouse fan at Potawot Community Garden, we will be using the following criteria and a weighted ranking system to understand the constraints of the project and to deliver a useable solution for our clients. Criteria which is valued as most important will rate at 10, while criteria which is least important will rank at 1. After meeting on site with the Potawot Community Garden team, these are the criteria decided upon by the group and the client.

| Criteria | Constraints | Weight

(1-10) |

|---|---|---|

| Functionality | The fans installed must be powerful enough to cool a 100 foot greenhouse to prevent blight and rot to crops susceptible to high temperatures | 10 |

| Programmability | Preferably, the fans would run on an automatic system rather than manual control | 8 |

| Reliability | The fans must be able to run at least 8-10 hours a day during peak summer hours | 10 |

| Readability | A thermostat added to the system is something our client was interested in having to monitor the temperature of the greenhouse | 7 |

| Aesthetics | The panels are to to be off the ground and arranged in a functional and aesthetic manner, either mounted on the fan box, on the roof of the green house or used to create a shaded rest area | 3 |

| Educational | Potawot is big on education and leading the way for other community gardens, an informational sign explaining the solar system would be desirable | 6 |

| Usability | The system should be simple enough that the client can use and possibly even replicate the system provided by the team | 8 |

| Monitorability | It's preferred by the client to provide some kind of way to monitor the amount of solar energy being produced by the panel as well as the cost savings | 5 |

Literature review[edit | edit source]

Greenhouse fan basics[edit | edit source]

Adding fans to a greenhouse can be useful when moderating the temperature within the greenhouse. While a primary function of greenhouses is to trap solar insolation, sometimes they can become too hot. Plants may overheat, wilt or result in crop failure. Without having proper ventilation and air circulation, plants also become susceptible to mildew caused by a buildup of condensation on the surface of the crop.[2]

Having regulated circulated air flow is also crucial for plant transpiration, the movement of water through a plant.[3] The height of the crops grown in the greenhouse also play a role in airflow and temperature. In a test of a ventilated greenhouse, by Shuhai Li, it was observed that better ventilation reduced temperature of leaves at the top of the plant, more so than the bottom.[3] This means that sometimes, other methods are needed to cut back even more condensation. One such method uses water absorbing materials to make Evaporative Cooling Pads.[3] These pads work in conjunction with fans to pick up the slack.

When installing fans, the most common place is to attach them to the back wall in order to force ventilation.[4] Potawot currently has two greenhouses that have fans attached in this manner that are run electrically throughout the summer. Another common method used on houses which are under 100 feet is to install pressure fans higher up on both end walls.[4] These fans are called Horizontal Airflow Fans (HAF) and instead of exchanging air with the outside of the greenhouse, HAF circulate the air within the greenhouse.[2] Fans are an important component to any greenhouse, reducing condensation build up and keeping consistently lower temperatures.

Solar energy[edit | edit source]

Solar Energy is an abundant renewable energy resource as it covers earth's surface with 120,000TW of radiation.[5] As the fastest growing energy source, solar can be a great solution to many of the energy issues we face today. All this sunlight allows for the solar panels to produce energy that can power almost anything. There are two different types of solar photovoltaic systems: Grid-direct or battery based. A grid-direct system is simply a system with no battery, this is typically the most common type of system as it requires less components that a battery based system.[6] The system we are building for Potawot's greenhouse will be a grid-direct system. A major downside to building a grid-direct system is that there's no room for storage since there's no battery. Photovoltaic Panels can be wired in one of two ways, in series or in parallel. To make a series connection, the positive wire is from one panel is connected to the negative wire of another panel, with this type of connection, the Current will stay the same while the Voltage ranges.[7] A parallel connection is a system where the positive wire of one panel is connected to the positive wire of another panel, this type of system will have a constant voltage and a changing current.[8]

Components[edit | edit source]

Photovoltaic module: The actual panels that are placed on roof's to generate electricity from the sun are called PV modules. Battery: Stores the energy produced by the panel for future use. Batteries connected together are known as a "battery bank". Inverters: Converts the DC power captured from the PV modules and turns it into AC power to power loads. Disconnect: Necessary component for safety, allow you to disconnect the solar panel from the inverter. Charge controller: Serves as a voltage regulator.

Greenhouse basics[edit | edit source]

Greenhouses are structures used for horticulture, as well as many other different agriculture projects, that use the sun's light and heat to its advantage. Depending on the location of the greenhouse there are different necessities for what the greenhouse has to contain. Some greenhouses need supplemental irradiation during part of the year due to the amount of sunlight being insufficient during that season.[9]There are also many different structural types of greenhouses and the greenhouses currently at the Potawot site are Quonset style.[10] This type of greenhouse has pipe arches throughout it supporting a transparent polyethylene, or similar material, cover.[10] This cover is important as it is how all the sunlight irradiance is held within the greenhouse. As the sun's short-wavelength Ultraviolet(UV) rays reach the greenhouse they pass through the cover and continue to the ground and plants. Once they reach the plants and ground the rays warm these areas and are bounced back as longer-wavelength infrared rays in the direction they came.[11] This warming of the ground and plants by the UV rays leads to the warming of the greenhouse as this warmth is trapped within and can't escape too easily. This brings the ventilation part of a greenhouse up as all of this warmth can't be healthy since too much heat can kill vegetation. A ventilation system for a greenhouse is integral as it helps control the temperature, humidity, and provides carbon dioxide for the plants.[12] With all of these variables under control, a greenhouse is able to successfully use the greenhouse effect to its advantage to help vegetation grow in areas it wasn't as able to before.

Prototyping[edit | edit source]

Rebecca[edit | edit source]

I went into this prototype stage hoping to learn how I could make an aesthetically pleasing solar shade for a picnic table. I learned that solar shades are actually around, after visiting Southern Oregon University a few years ago. Their function is to provide shade as well as a charging station for personal electronics like phones and laptops. I wanted to see if I could apply this to our fan project since the solar panel has to go somewhere. Since the garden has also requested a monitor to see the power the panel captures, the picnic table could be a place to instal that monitor and serve as a meeting space. My choice to use LEGO for the prototype was mostly my desire to work with my hands and have a tangible idea that I could hold. Working with LEGO really helped give me a sense of how our product could look after installation.

Ines[edit | edit source]

I think one thing I was hoping to learn more about was how the panels would connect to the fans, this is one piece I was having a hard time imagining. I feel good about how the panel works & why we may want or may not want to include a battery within the system but, for me, connecting the panel to the actual fan is the most intimidating part of the project. While working on my prototype, I learned that your first idea isn't always going to be the best idea, originally I was hoping this assignment to use the plastic straws my roommate & I collect but the plastic straws were not having it so I decided to cut a plastic soda bottle in half & then built my prototype around that piece. I also watched a couple youtube videos of folks walking their viewers through their own solar powered fans and learned that the panel & the fan connect to each other directly & it can be rather simple to do so. We'll need to use an exhaust fan instead of a ventilator fan so while the fan is running it will simultaneously let out hot air.

Chris[edit | edit source]

What I hoped to take away from this prototyping was a better grasp for what this project is going to need, parts wise. I wanted to understand what parts were necessary and why as well as what parts weren't necessary and why. I hoped to get a better understanding of what the project is actually going to be since I haven't actually been able to visit the project site. I think I actually did come out with a better understanding of what the project will need for parts as well as just a better grasp on the overall project. Having to create a prototype made me start really trying to figure out how this project was going to practically work. It made me come up with questions regarding the project and invoked new enlightening thoughts about the system we will set up. I learned these new aspects of the project through having to create the prototype. At first I was thinking of the system using a battery, but then I reread the To Catch the Sun components section and saw that greenhouse fans normally don't require one. For some reason, I had thought that ventilation would be needed even when the sun wasn't out, but that probably wouldn't be the case as on those days it will be cooler in the greenhouse. This prototyping assignment made me look at the project differently since I was looking at it through a practicality lens rather than a theoretical lens as we had with past assignments.

Foster[edit | edit source]

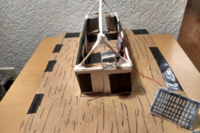

Designing the prototype for this project I had hoped to learn possible positions that the solar panel could gather the most amount of sun for the longest. With the help of google maps and several in person measurements and photos I had been able to construct a reasonably accurate scale for the greenhouse. In the process finding the most likely wiring connections and pathways to the main power control if the solar panel is placed away from the greenhouse.

I enjoyed learning about the wide variety of approaches that can be taken in order to solve the solar panel setup. Some of the restrictions are having the solar panel be placed on the greenhouse in a way that will restrict sunlight from reaching crops inside. In addition the area has several trees close enough to impact lighting for the solar panel in the winter if it is placed with poor consideration. This is why constructing a model and having the ability to reconfigure the placement of the solar panel is an important tool.

Using simple materials such as cardboard, wooden skewers, sharpies and lots of tape can create an efficient way to construct a relatively realistic model for demonstrational purposes. Using in person measurements on site can bring further clarity in depicting the greenhouse dimensions and personality. Using satellite imagery with google maps can confirm the placement of nearby geographical features such as agriculture and natural obstructions. As our project continues to transition from paper to reality the greenhouse model can be reflected upon while new changes are being made.

Prototype gallery[edit | edit source]

Here is a gallery of Team Pelican's various prototypes, including more fanciful creative ideas as well as practical considerations and wiring solutions. The team really took the opportunity to get creative and work with visual modals.

- Prototype Gallery

-

One option for solar panel placement featuring a picnic table.

-

Panels connected to the fans.

-

This approach is closest to what we actually ended up with.

-

This design uses two smaller fans rather than one large one.

-

Another alternative for the placement of the panel.

-

A roaming platform for the panel.

-

This is our prototype for the wiring of the solar powered fans.

-

This is an alternative that uses a battery. A possible upgrade for the future.

Construction[edit | edit source]

Construction Components[edit | edit source]

The Snap-Fan kit that we purchased for the garden included a 28" DC fan, a shutter, a thermostat, and a solar panel. A wooden fan mount was also required and made out of wood. To secure the solar panel, we also purchased a panel mount which required assembly. Unfortunately, our solar panels did not arrive in time to complete construction on the project. A pole mount was also purchased from amazon to keep the solar panel off the ground, but without the panel, the final installation still needs to be completed.

- Constuction Gallery

-

Wood for the fan mount.

-

Drilling the wood to make the fan mount.

-

The wooden mount for the fan.

-

The 28" Snap-Fan.

-

Shutter in the open position.

-

Shutter for the fan.

-

Fan thermostat.

-

The components for the solar panel mount.

-

Solar mount assembled.

-

The mounting hardware for the fan box.

-

Mounting the fan box to the greenhouse.

-

Fan mounted to the frame.

-

Shutter also mounted to the frame. This was the farthest stage of our construction.

Proposed Timeline[edit | edit source]

This table details our schedule to complete the project. As a team, we did our best to stay on schedule, but there were several delays which pushed back some of our original deadlines. Parts were not ordered until 4/22/21 which is rather later than we had originally planned. We struggled to find a good solution for Potawot and in finalizing our design. We also faced another difficulty in the final assembly of the project as the components arrived at the garden at different times. As of 5/6/2021, the solar panel has not yet arrived. Until the panel is on site, completion of the project will remain pending. Currently, it's set to arrive on 5/12/201 where Potawot will continue on with the installation. Our group realizes that parts should have been ordered sooner, yet we believe that under the current conditions of distance-learning, a pandemic, and general shipping delays, we did our best with the situation we find ourselves in.

| Date | Description | Status |

|---|---|---|

| 3/14/21 | Take more photos and measure dimensions of the greenhouse in order to make a 3D model | Complete |

| 3/17/2 | Research materials/technology | Complete |

| 3/21/21 | Propose final budget | Complete |

| 3/23/21 | Meet with Potawot on Zoom | Complete |

| 3/28/21 | Finished Prototype of the product | Complete |

| 3/30/21 | Meet with Potawot on Zoom to present prototypes | Complete |

| 4/4/21 | First photos of final design | Complete |

| 4/7/21 | Inform all group members of system progress and set intentions on how to continue the build | Complete |

| 4/9/21 | Order parts (delayed to 4/22/21) | Complete |

| 4/11/21 | Second photos of final design | Complete |

| 4/18/21 | Finished Design of the product | Complete |

| 4/25/21 | Assembling the product (delayed to 5/7/21) (final assembly not completed) | Incomplete |

| 5/2/21 | Install the finished product and publish final Appropedia page | Complete |

Tentative Budget[edit | edit source]

This is a table of our expenses to build all the necessary components to mount the fan to the greenhouse. The fan-kit was purchased directly by Potawot, and the remaining supplies were generously paid for by CCAT at Cal Poly Humboldt. Other minor costs, such as wood filler and putty knife were paid for by the team and not included in this chart since there will be additional uses for those materials in a personal setting.

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 2 | 28" Snap-Fan Solar Kit | Snap-Fan | $1800 | 1800.00 |

| 32 ft | Wood for fan mount | The Mill Yard | $52.80 | 1852.80 |

| 1 lb | Screws | The Mill Yard | $8.49 | 1861.29 |

| 1 | Solar Panel Pole Mount | Amazon | $68.23 | 1929.52 |

| 8 | 3/8" x 4" Hex head lag screw and washer | Ace Hardware | $7.12 | 1936.64 |

| 8 | 3/8" Washers | Ace Hardware | $1.28 | 1937.92 |

| 16 | Corner Brace 4x7/8 | Ace Hardware | $28.72 | 1966.74 |

| 4 | Pipe Strap 1" | Ace Hardware | $3.16 | 1969.90 |

| 4 | Pipe Strap 1-1/4 | Ace Hardware | $3.96 | 1973.86 |

| 1 | Strap Hanger 3/4x10' | Ace Hardware | $2.99 | 1976.85 |

| 2 | Hose Clamp 8"-14" | Ace Hardware | $9.98 | 1986.83 |

| Total Cost | 1986.83 | |||

Operation[edit | edit source]

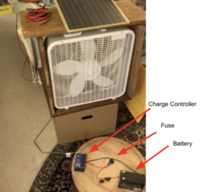

The kit purchased form Snap-Fan.com utilizes a 28" fan and shutter, a 24V 60 Cell solar panel, thermostat, all mounted to a wooden fan box. As seen in the diagram below, the DC fan is directly connected to the solar panel with the thermostat and a fuse in the positive line. Since this is a direct connection, the team did not end up using a battery as it would nearly triple the cost. In order to keep a battery sufficiently and safely charged, two additional panels per fan would have been required. Unfortunately, the client had expressed interest in a battery for storage, but it was out of this projects budget and technical scope. The good news is that this system can easily add a battery at a later time.

-

Wiring diagram for the fan.

-

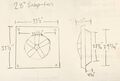

The dimensions of the fan.

-

Instructions to build the mounting box and the dimensions of the shutter.

Maintenance[edit | edit source]

All parts of this kit are replaceable at Snap-Fan.com and come with a 2 year warranty. The fan blades are made out of polypropylene airfoil with a di-cast aluminum hub to ensure balanced rotation and a quiet fan.

Schedule[edit | edit source]

This system must be regularly checked to insure the best performance. The shutter should help protect the fan from the elements when it's not active. Since the system comes with a 2 year warranty, all of the components should be visually inspected at the end of that two years.

Instructions[edit | edit source]

To replace any of the parts, first the fan must be disconnected from the power supply (solar panel) then the fuse must also be removed to ensure safe maintenance.

Replacement parts can be obtained by contacting Snap-Fan at 707-822-7627 or by emailing support@snap-fan.com.

For ease of maintenance, having the item#, model# or part# is required.

Here is a list of the parts used in this project:

- 28" DC Snap-Fan: part #2800

- 28" Snap-Fan Exhaust Shutter: SKU: 6908

- 10 amp DC Thermostat: SKU: 1039

Conclusion[edit | edit source]

Testing[edit | edit source]

At this time (5/12/2021) no testing of the system has taken place since the project was not completed within our proposed timeline. Team Pelican deeply regrets not being able to test our design.

If tests could have taken place, we would have liked to test the current, voltage, and power of the fans and panels, as well as comparing the air temperature in the greenhouse with the fan off, and on.

Discussion[edit | edit source]

One positive result we got was the ease of Snap-Fan's instructions detailing how to construct the fan box, and how to mount the box to the existing greenhouse frame. We were also able to successfully mount the fan, and shutter to the frame. We were very proud of the work that we completed, even though the panels did not end up arriving on time for the full installation.

Lessons learned[edit | edit source]

Team Pelican learned many valuable lessons while working on this project. One of our main takeaways, was learning how to interact with a client and trying to accommodate their needs. We also learned that it is much more costly to have a battery included in the system, and that it is much easier to connect the fan to the solar panel directly. Not only will this make the system last longer, but it also removes the necessity to provide a secure, weather and theft proof way to store the battery. Perhaps the biggest lesson we learned, is the uncertainty of getting things shipped. After the parts were finally ordered, they did not all arrive at the same time. We can only hope to grow from this experience. Everything in life is a learning experience, and we all have had our fair share of struggles during the pandemic. What's important is so to stay positive, and remain in good communication with those involved. Finally, the most humbling and heartwarming lesson we learned is the understanding of people. Even though we did not finish as much as we hoped, several members of the garden still parted ways with the team expressing gratitude for making good headway on this project. The garden team was very open and supportive of our ideas, and patient with our learning process.

Next steps[edit | edit source]

Originally, we intended to install two fans to our greenhouse but because of our approaching deadline, we scaled down and decided to focus on installing only one fan for the present time. However, the garden has all of the necessary parts to follow our design and install a second fan at their discretion. Both fans may be placed in the same greenhouse, but Potawot had also expressed interest in using the extra fan for another greenhouse which currently does not have any.

Another step that could be taken up either by Potawot or a future ENGR 305 class is installing the battery and additional panels required.

Troubleshooting[edit | edit source]

Although we did not conduct testing, this table details some of the other problems our group ran into while building what we could.

| Problem | Suggestion |

|---|---|

| Cutting Woos | It may be worth it to pay the extra $2 per cut at the lumber yard to ensure even cuts |

| Shipping Time | If we were to do this project again we would try harder to make sure that all the components arrived on time |

| The Battery | If more money could be raised, then a battery with the needed panels could be added to the system |

| Email Communication | Being more diligent about emailing the client would have made this project go more smoothly |

| Lack of Expertise | Reaching out to an expert was the final push we needed to design our system, and doing it sooner rather than later is a idea. |

Team Members[edit | edit source]

- Rebecca Asbury

- Chris Lo Greco

- Ines Morales

- Foster Smith

References[edit | edit source]

- ↑ 1.0 1.1 1.2 1.3 1.4 United Indian Health Services, 2021."Caring for our Native Community since 1970." 1 March, UIHS. http://unitedindianhealthservices.org/

- ↑ 2.0 2.1 Pressman, Andy, and Thea Rittenhouse. GREENHOUSE MANUAL An Introductory Guide for Educators. Washington, DC: United States Botanic Garden (USBG), 2001.https://www.usbg.gov/sites/default/files/usbg-greenhouse_manual.pdf

- ↑ 3.0 3.1 3.2 Li, Shuhai. "Comparing the performance of naturally ventilated and fan ventilated greenhouses." (2007).https://repository.lib.ncsu.edu/bitstream/handle/1840.16/4759/etd.pdf?sequence=1

- ↑ 4.0 4.1 Worley, John. "Greenhouses Heating, Cooling and Ventilation." (2014). https://secure.caes.uga.edu/extension/publications/files/pdf/B%20792_6.PDF

- ↑ Reddy, P. Jayarama. Solar Power Generation: Technology, New Concepts and Policy, Taylor & Francis Group, 2012. ProQuest Ebook Central, https://ebookcentral.proquest.com/lib/humboldt/detail.action?docID=888587.

- ↑ Mayfield, Ryan. 2019. Photovoltaic Design and Installation For Dummies. 1st edition. For Dummies.

- ↑ Mayfield, Ryan. 2019. Photovoltaic Design and Installation For Dummies. 1st edition. For Dummies.

- ↑ Mayfield, Ryan. 2019. Photovoltaic Design and Installation For Dummies. 1st edition. For Dummies.

- ↑ Hanan, Joe J. "Introduction and Structures: Locations, Styles, and Covers." Essay. In Greenhouses: Advanced Technology for Protected Horticulture, 1–18. CRC Press, 2017

- ↑ 10.0 10.1 Anand Agricultural University. "Design and Maintenance of Green House." Design and Maintenance of Green House: Lesson 13 Solar Radiation in Greenhouses. Accessed March 1, 2021. http://ecoursesonline.iasri.res.in/mod/page/view.php?id=124136.

- ↑ Jacob, Daniel J. "The Greenhouse Effect." Chapter. Introduction to Atmospheric Chemistry, 115–138. Princeton University Press, 2011.

- ↑ Eyerly Family. "Greenhouse: Do They Need Ventilation." Farm & Garden DIY, April 7, 2020. https://farmandgardendiy.com/do-greenhouses-need-ventilation/#:~:text=Yes%2C%20greenhouses%20need%20ventilation.,does%20to%20keep%20plants%20healthy.&text=Now%20that%20you%20know%20greenhouse%20ventilation%20is%20important%20for%20healthy%20plant%20growth

- United Indian Health Services, 2021."Caring for our Native Community since 1970." 1 March, UIHS. http://unitedindianhealthservices.org/

- Paul Holmes, Shalve Mohile. 2021. Solar Power for Beginners: "How to Design and Install the best Solar Power System for your Home." April 29. Manhattan, Monkey Publishing.

- Emily Patrick. 2020. Solar Greenhouse For Beginners And Dummies: "A complete Guide On How to Design and Built a Net-Zero Energy:

A Complete Guide On How to Design and Build a Net-Zero Energy Greenhouse." October 3. Independently Published.