Vending machines operate 24 hours per day, seven days a week and can use large amounts of energy throughout those hours of operation. In addition to consuming 2,500 to 4,400 kilowatt-hours (kWh) of energy per year at average electricity costs of about 8 cents / kWh,[1] the annual operating costs can range from $200 to $350.

New, efficient vending machines are available that can greatly reduce operating costs through the use of infrared motion sensors. These sensors allow some of the machines functions to only work when a person is present in front of the sensor. The compressors run only enough to maintain a suitable temperature throughout the workday while the lights and other components remain off in order to minimize overall energy consumption.[2]

The ECM file can be downloaded here: File:ECM - Motion Sensor Vending Machine Feb. 18.xls

The Technology[edit | edit source]

Duty Cycle and Control Logic

The typical duty cycle of a vending machine controlled by a motion sensor is determined by whether people are around the machine or not. Usually power is cut off to the machine within 15 minutes of a person's presence in front of it, which is a preprogrammed amount of time that allows for a complete cooling cycle to take place. Most devices are designed to shut off for approximately 2 hours and then turn back on activate a compressor cycle in order to maintain an optimal interior temperature. When a person walks up to it, the machine lights, electrical components and compressor are activated in order to provide service for the person. In order to prevent high pressure mid-cycle compressor restarts, general control logic ensures that it is allowed to run a complete cooling cycle before it shuts down.[3]

Passive Infrared Sensors

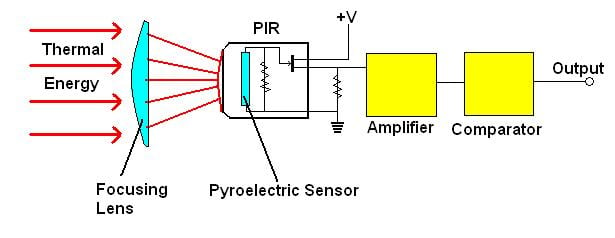

Most vending machine sensors use passive infrared (PIR) sensors, which unlike optical sensors that use an LED transmitter and infrared receiver, emit nothing. Rather than radiating, the PIR responds to infrared energy emitted by any nearby objects. Any object with a temperature above zero degrees Celsius emits infrared energy, through black-body radiation. Invisible to the human eye, the magnitude of this radiation varies with temperature, which is exactly what makes the PIR function the way it does.

Although invisible to the human eye, the magnitude of infrared energy can be quantified by a pyroelectric sensor. This sensor is placed behind an infrared-transparent cover, so that it may monitor objects with varying infrared energy. Similarly to the way an electric charge is created when visible light strikes a solar cell, these sensors generate a small charge when subjected to infrared energy. As an object with a more intense infrared energy, such as a person, is detected by the sensor, it overlaps a section on the chip that had previously been subjected to some much cooler object, such as a wall in the background. The pyroelectric sensor is connected to an energized relay, which acts as a "switch," completing the load circuit. As this warmer, or more energized object, moves along the lens of the sensor, the relay becomes de-energized, the contacts of the relay become operational, activating the detection switch of the control panel. Similarly, if an object colder than the background wall is presented into the field of view of the sensor, the difference in infrared energy will still cause the relay to be de-energized, activating the detection switch.

False Activation Prevention

Many other objects tend to emit an undesirable amount of infrared energy - at least to the vending machine sensor's point of view. Something as simple as flicking on a light switch can produce a sudden change in infrared energy that the sensor will undoubtedly pick up. In a room where lights are constantly turned on and off, this would prove to be a major inconvenience, turning the machine on and off repeatedly without the intent to actually vend. The unit's comparator solves this problem by ignoring objects that emit a constant source of infrared. Therefore, if a new "heat spot" shows up on the sensor and stays constant in its place and level of emittance (ie. an object emitting infrared does not move across the sensor), the comparator 'decides' not to send a signal, triggering the machines start-up.

The model below outlines a simple diagram of the inner workings in a passive infrared sensor.[4][5]

The inner workings of a PIR Sensor

Economic Value[edit | edit source]

Vending machines account for a significant portion of annual energy use and are often overlooked when considering saving energy and money. Each machine can use up to 400 W at a rate of approximately 8 cents / kWh[6] can result in a cost of about $300 per annum to operate the machine.

Studies have shown that the addition of motion sensors can reduce the overall annual operating cost by 30 to 50%. This could potentially save $150 per machine per year in electricity. Popular brands of motion sensors / controllers cost approximately $200,[7] resulting in a payback period of approximately 1.5 years.[8]

Emission Reductions[edit | edit source]

A decrease in energy consumption translates to a reduction in carbon dioxide emissions from the burning of fossil fuels. The specific reduction in greenhouse gas emissions is dependent on the energy supply mix that provides power to the organization.

Below is a breakdown of the energy supply mix in Ontario as of 2005:[9]

- Nuclear: 51%

- Renewable: 23%

- Natural Gas: 7%

- Coal: 19%

The EPA released U.S. data that relates energy production of various sources to the resulting carbon dioxide emissions.[10] The U.S. data was analyzed to determine the average carbon dioxide emissions released by each energy source and then compared to Ontario's energy supply mix. The result is approximately 0.222 kg of carbon dioxide is emitted in Ontario for each kWh of energy produced.

Using an average value of 3494 Kwh consumed per year for standard refrigerated vending machines and an estimated 46% energy reduction by switching to motion sensor controlled vending machines, the energy savings is approximately 1607 kWh each year. This translates to an annual reduction of 0.35 tonnes of carbon dioxide emissions for each converted vending machine. Using the most recent cap and trade legislative framework proposed in the Kerry-Boxer Bill for North American markets, it is estimated the value of carbon will be close to $15 per tonne.[11] Therefore, if a cap and trade program were to be implemented, the additional benefit would be $5 per year for each vending machine outfitted with a motion sensor.

Health Effects[edit | edit source]

The National Research Council has investigated the external costs associated with power production in the United States. A study sought to determine the cost to society to convert each source of fuel into energy. The study focused primarily on natural gas and coal and found the external costs per MW to be $1.6 for natural gas and $32 for coal, not including climate change effects.[12] Based on the energy supply mix in Ontario, the external health effects total $6.19 per MW of energy consumption. Therefore, by reducing energy consumption by 1607 kWh, the external health effects equates to an annual benefit of approximately $9.95 per vending machine.

Energy Saving Alternatives[edit | edit source]

The following is a list of suggestions that can further reduce the energy usage and savings of the vending machines:

- Remove light bulbs or replace current light bulbs with more energy efficient device (ie. CFL or LED)

- Reduce the operating temperature of the machine if appropriate

- Locate the machine away from heat sources in cooler areas

- Attempt to use an alternative other than vending machines (ie. Bring your own water)

- Regularly clean coolant coils and ensure machine is properly maintained

Links[edit | edit source]

References[edit | edit source]

- ↑ EnergyShop (2010), Residential Electricity Rates, http://www.energyshop.com/es/prices/ON/eleON.cfm?ldc_id=348&

- ↑ E Source Companies LLC (2009), Vending Machine Energy Savings, http://web.archive.org/web/20130527063656/http://www.mge.com/business/saving/madison/PA_50.html

- ↑ E Source Companies LLC (2009), Vending Machine Energy Savings, http://web.archive.org/web/20130527063656/http://www.mge.com/business/saving/madison/PA_50.html

- ↑ Machine Design (2008), Sensor Sense: Passive Infrared Motion Sensors,http://machinedesign.com/article/sensor-sense-passive-infrared-motion-sensors-0710

- ↑ Wikipedia, Passive Infrared Sensor,http://en.wikipedia.org/wiki/Passive_infrared_sensor#PIR-based_motion_detector

- ↑ EnergyShop (2010), Residential Electricity Rates, http://www.energyshop.com/es/prices/ON/eleON.cfm?ldc_id=348&

- ↑ Vending Miser (2010), Vendingmiserstore.com, http://www.vendingmiserstore.com/index.php?s=g&gclid=CMflgtqF3J8CFQSbnAod_zDQHA

- ↑ State Energy Office (2005), Vending Machines – Utility Savings Initiative (USI) Fact Sheet, http://www.p2pays.org/energy/Vending.pdf

- ↑ Ontario Power Authority (2005), Supply Mix Advice and Recommendations, http://www.powerauthority.on.ca/Report_Static/1139.htm

- ↑ Department of Energy & Environmental Protection Agency (2000), Carbon Dioxide Emissions from the Generation of Electric Power in the United States, http://www.eia.doe.gov/cneaf/electricity/page/co2_report/co2emiss.pdf

- ↑ Point Carbon (2009), "Carbon to Cost $15 per Tonne Under Kerry-Boxer Bill", http://web.archive.org/web/20120712051022/http://www.pointcarbon.com:80/aboutus/pressroom/pressreleases/1.1249271

- ↑ National Research Council (2010), "Hidden Costs of Energy: Unpriced Consequences of Energy Production and Use", http://books.nap.edu/openbook.php?record_id=12794&page=4