Adjustable Monochromator. A monochromator is a device which takes light and transmits it to into a narrow band of wavelengths. Using a form of mechanical filtering (diffraction) the user is able to select a specific wavelength (color) which would exit through a exit slit. The monochromator holds many scientific applications ranging from measuring a reflected or transmitted light off a surface. By branching two assemblies together, one can produce a excitation wavelength aiming at the second which can analyze the emitted light.

The basis of this project was derived from a early project Bproman and Ajrettig developed based around making an affordable piece of lab equipment. The design used a whole CD which was fixed, thus causing it to struggled to focus the wavelength and the exit slit had to be set manually by sliding a printed shroud. This design used the previous concept with an addition of a rotating reflective surface which aims the wavelength to an exit slit which can be finally adjusted to a desired wavelength.

Previous Design: [1]

New Design:

Bill of Materials[edit | edit source]

- PLA Printing Filament (1 kg) - $14.99 [2]

- Blank CD (Can be replaced with any CD) 25pk - $7.79 [3]

- Box Cutter Blade 100 pk - $9.98 [4]

- M3 8mm Socket Head Cap Screws 25 pk - $3.23 [5]

- M3 25mm Socket Head Cap Screws 100 pk - $11.79 [6]

- Ballpoint Pen Spring (any spring) $9.99 100pk - [7]

Download CAD and STLs Here [8]

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

- M3 Metric Short Arm Allen Wrench [9]

- Utility Knife - [10]

- LED Flashlight - [11]

Skills and knowledge needed[edit | edit source]

- Monochromator [12]

Technical Specifications and Assembly Instructions[edit | edit source]

Parts (Qty 1 for all)

- Body2

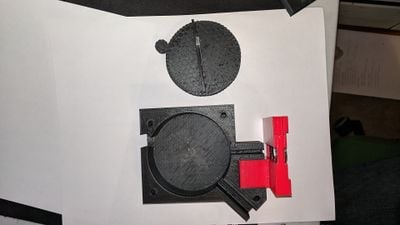

- Body Cover

- Light Slit Left

- Light Slit Right

- Light Reflector Gear

Printing

- Material: PLA or Equivalent

- Support: None

- Layer Height: 0.2mm

- Printer Speed: Varies based off Model, choose a speed in order to give best print quality

- Print Temp: Choose based off material selection for best print quality

- Specific Part Instruction:

Gears

- Density: 100%

- Walls: 4

Rest of Components:

- Density: 15%

- Walls: 2

Estimated Time - 7 hrs

Installation

Estimated Time - 30 min

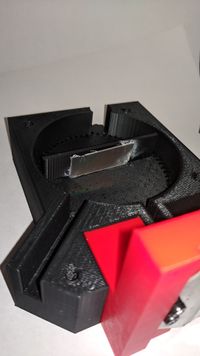

- Take Left and Right Slit, using 3M 8mm screws attach a box cutter blade to each of the components. See Picture below

- Using a 3M 25mm screw feed it through the hole located on the side of the Right Slit part.

- Place the pen spring over the screw

- Using the guiding rails, secure the left and right slit. (do not over tighten as this is your calibration screw for the the slit thickness)

- Carefully using a sharp blade, cut a small reflective piece out of a CD

- Glue the reflective surface to the tab on the larger gear. See picture below for arrangement.

- Place the gears on their respective shafts of the body component, these should be loose enough to still allow rotation. Clean up as needed based off printer quality.

- Place the slit assembly with the body assembly, this should be a tight fit. See picture below for alignment.

- Place the Body Cover over the whole assembly lining up the holes.

10. Secure with M3 25mm screws

How To Use/Adjust

- Place a light source at the opening, preferably a single white LED source.

- Wavelengths can be adjusted by moving the small gear located in the rear of the assembly.

- Slit thickness can be adjusted by tightening or loosening the M3 25mm screw located on the side of the slit assembly.

Common Problems and Solutions[edit | edit source]

Shattering CD - When cutting the CD to size, be sure to use a fresh blade and carefully cut using a straight edge till all the way through the CD.

Reflective Surface - When cutting be careful, reflective surface may flack off or peel. If it occurs cut a new section.

Cost savings[edit | edit source]

Cost of Production

$0.37 - Gear A + B

$0.22 - Light Slit Left

$0.13 - Light Slit Right

$0.70 - Body Cover

$0.99 - Body

$0.31 - Blank CD

$0.20 - 2x Box Cutter Blade

$0.52 - M3 8mm Screw

$0.47 - M3 25mm Screw

$0.20 - 2x Pen Spring

Total = $4.11

Commercial Equivalent

Newport: $5000-$8000 [13]

Edmund Optics - Mini Chrom (Specific Range): $1500 [14]

ScienceTech: $5000-$10000 [15]

Savings

Mini Chrom Comparison - 364.96%

Standard Edition Comparison ($5000) - 1217%

Benefited Internet Communities[edit | edit source]

Gathering for Open Science Hardware (GOSH) - [16] - A movement that seeks to reduce barriers between diverse creators and users of scientific tools to support the pursuit and growth of knowledge.

Spiderwort - [17] - A open source group that has released several scientific designs and continues to develop open source kits that could be used in schools, labs and garages.

Open-Labware - [18] - A community that focues on consumer-oriented 3D printers based off the "maker movement" pushing for prototypes of complex products in owns own garage.

PhysicsOpenLab - [19] - A physics based community that openly shares designs for scientific equipment for people to make at home.

SciencetoyMaker - [20] - Focuses on making cheap fun science based toys for children which makes learning fun.

References[edit | edit source]

- Monochromators Wiki Available: https://en.wikipedia.org/wiki/Monochromator.html

- Shimadzu Corportaion - Monochromators Fundamentals Available: https://www.shimadzu.com/an/uv/support/fundamentals/monochromators.html#2

- Castor Classes Youtube.com - Monochromator Video Available: https://www.youtube.com/watch?v=87-omb2tSv8 .