History[edit | edit source]

The notion of building walls with sandbags or earthbags has been around at least 100 years.[1] Originally and into modern times these have tended to be burlap (hessian) fabric bags forming temporary structures acting as flood barriers or as military fortifications. It is unclear exactly when this was done for the first time,[2] but there is some evidence that in military settings sandbag walls were being used prior to World War I. Indeed, some WWI trenches reinforced with oil-impregnated sacks still survive, despite being intended to be temporary.[2]

Building permanent structures such as homes using earthbags is a more recent development.[1] Otto Frei experimented with earthbag building in the in 1960s in Germany.[3] In the 1970s, again in Germany, Gernot Minke and others at the Research Laboratory for Experimental Building at Kassel Polytechnic College were investigating ways of building earthquake resistant structures without cement. They used polyester and burlap tubes filled with pumice to make domed structures. With the Francisco Marroquin University in Guatemala and the Centro de Estudios Mesoamericano Sobre Tecnologia Apropiada (CEMAT) a structure was built in Guatemala in 1978 out of lime soaked cotton fabric bags filled with pumice sand.[4]

The Earthbag building method was popularized by Persian Architect Nader Khalili. Khalili combined the adobe method of construction, which he had been exposed to in his homeland, with the idea of sandbags. In 1984 Khalili suggested filling bags with moondust as a solution for building habitations on the moon. He refined the technique by using barbed wire between courses and moving from sand as a filler material to moistened adobe soil or cement stabilized soil. Later, he started using long tubes of polypropylene as flexible forms to create domed structures. He called the technique Superadobe.[5] Khalili went on to publish 6 books and found the non profit organization Cal-Earth Institute (California Institute of Earth Architecture) in 1981.[6] He has been criticized for claiming his superadobe technique was "freely put at the service of humanity and the environment" at the same time as attempting to patent earthbag building techniques in very general terms in 1991. It is claimed he requested that all other promoters of earthbag building enter into a contract with him to continue their work.[1]

Joe Kennedy was the first person to use the term "earthbag", in reference to the idea that the filler material could be a variety of different materials or earthen mixtures.[5]

Terminology[edit | edit source]

Contained earth is the basic technique of filling containers with earth. Modular contained earth is the use of bags or tubes in walls which rely on rebar and/or strands of barbed wire between courses to keep the form of the wall. Flexible form rammed earth is another term that has been used.[3]

Contained Sand uses sand fill or any fill too dry or with poor cohesion that performs structurally like sand bags. Such bags must be solid-weave fabric have good protection from fabric damage. Contained sand needs more vertical reinforcement than contained earth. Structurally, alternative loose fills (like rice hulls) will create a wall more similar to contained sand than to contained earth.

Contained Gravel uses fill of any aggregate larger than coarse sand. Contained gravel can function as concurrent footing and footing drain material, and can use either solid-weave or mesh containment.

Superadobe[edit | edit source]

Superadobe was the term used by Nader Khalili to refer to using continuous tubes rather than individual bags.

Hyperadobe[edit | edit source]

Hyperadobe (Solid contained earth) was developed by Fernando Pacheco of EcoOca in Brazil. A pliable knit raschel mesh tube is used, the same material used in packaging fruit. This mesh allows the earthen fill to solidify between courses as long as the fill is built damp. Solid contained earth has higher shear and out of plane strength than modular contained earth of the same soil, and may allow the use of wire mesh in addition to or in place of barbed wire.

Materials[edit | edit source]

- Containers (i.e. Bags or tubes)

- Filler material (usually adobe, with or without cement stabilizer)

- Barbed Wire

- Gravel (for french drain, or for foundation courses).

- Wood for concrete framing, for door frames and window frames

- Concrete (to add as filler material or for bond beams or lintels).

- Nails

- Rebar

Containers[edit | edit source]

The basic vessel for contained earth building may be either numerous bags/sacks which are used as individual bricks, or long tubes which become the entire course in a wall.

The size of the bags determines the width of the wall, and thus influences the stability and strength of the wall, the amount of filler material required to fill each bag / course, and the amount of physical effort required during building. Empty bag sizes are typically given by manufacturers. Various sizes have been recommended, but this is often simply a reflection of the availability of bags from suppliers, and the exact size is not critical.[5]

45 cm x 70 cm .[7] 45 cm x 76 cm (18 inches x 30 inches).[2] 45 cm x 81 cm (18 inches x 32 inches).[5] 48 cm (19 inch) tubes.[8]

However, it is not recommended to build an earthbag wall which has a final width of significantly less than 18 inches.[5] If a range of different sizes are sourced, larger bags are better at the base of the wall, while smaller bags are more suitable at the top, or to make dome roofs.[5]

The fabric used in bags or tubes may be a solid weave or a mesh. Gusseted bags can be used.[7] These have an additional piece of fabric (a gusset) added to the sides or bottom of the bag, which adds more space and strength. Gusseted bags allow for more flat vertical surface once they are tamped into place. Non gusseted bags tend to leave their corners sticking out,[5] adding extra work to the plastering stage. One author advised hammering the corners in before plastering, or turning each bag inside out before filling it.[5]

Polypropylene bags[edit | edit source]

Polypropylene (also termed polypropene) is often recommended. is the second most commonly produced plastic in the world. Solid weave Polypropylene bags or tubes are the most popular type of container in earthbag building. Woven polypropylene material is able to breathe slightly, and is recommended rather than other solid, non-breathable materials.[5]

Polypropylene is cheap, durable, resistant to rot, water damage and insects. A study reported that polypropylene fabrics may have a half life of 500+ years in benign environments.[9] The tensile strength of such bags is higher than steel,[9] and they are resistant to circumferential forces produced by load bearing.[9] Polypropylene is vulnerable to ultraviolet damage and therefore is left covered from the Sun during construction and plastered once the structure is finished. Polypropylene fabrics may be stabilized/treated are intended to have greater UV resistance, but this may equate to a few weeks or months extra survivability in sunlight at best. Recommended grammage for polypropylene bags is 4 g/m.[8]

Since this type of bag is often used for grains or animal feed, they may available very cheaply as industry surplus. Misprinted bags may be available for a lower price.[5]

Polypropylene tubes (Superadobe)[edit | edit source]

Long rolls of polypropylene tubing are available from manufacturers. These large rolls of tubing are normally intended to be cut and stitched into individual bags and then used as rice bags, etc. They can be bought as huge rolls, up to 6000 feet (1830 meters) long.[5] Despite the fact that it requires extra stages in a factory to turn these rolls into individual bags, the rolls are usually no cheaper than the equivalent quantity of bags.[5]

Burlap[edit | edit source]

Burlap sacks are sometimes used, being seen by some as a more organic, "natural" material.[2] However, burlap sacks are often treated with hydrocarbon mold inhibitors which can cause allergic reactions in some individuals.[10] Burlap sacks are not as durable,[2] and are vulnerable to rot.[11] Burlap sacks can be more expensive relative to polypropylene.[2]

Mesh (Hyperadobe)[edit | edit source]

Mesh tubes can be used, for example, the hyperadobe technique. This type of mesh is used for fruit packaging.[5] The material is usually polyethylene of polypropylene in a "Raschel weave", which is similar to a net with lots of holes. This material is designed to allow air to circulate, which maintains freshness of produce during transport and storage. Such mesh is obviously not suitable for loose filler materials, and must be used with an adobe earth or cement stabilized filler material which will set hard.[5] There is no need to use barbed wire with the mesh, since the holes allow the filler material of successive courses to directly bond together, which results in a monolithic wall. Once set, the strength of the container material is no longer so important with mesh and such filler materials.[5] This mesh material is usually cheaper than solid weave polypropylene.[5] The holes allow the filler material to set faster, and enable plaster to adhere more easily.[5]

Filler material[edit | edit source]

The nature of the fill material determines the structural and thermal properties of the wall. For example different fill materials may provide thermal mass effect (dense fill materials) or insulation (porous, air filled materials).[11] Earthbags containing gravel may also act as non-wicking, partially insulated foundations.[11]

As a general rule the weaker the fill material, the stronger the fabric of the container must be.[2] For instance, a hard setting filler such as adobe relies little on the containers. Once adobe is fully set, the containers could be removed without any reduction in structural integrity.[2] Conversely, a very fine material such as dry sand relies entirely on the long term strength of the material used to contain it.[2]

Earth / Soil[edit | edit source]

Generally, earth is harvested from the build site. It is more efficient to use earth from other planned excavations such as pools or a septic tank.[7] The most convenient source of earth for the earthbag structure might be its own foundation trenches.

The make up of soil can be assessed without special equipment via simple tests such as the drop test and the roll test.[9] Another simple test is to use a jar of water. Add the soil, shake it and leave it overnight. Sand will sink to the bottom, followed by a layer of silt, and finally the clay will settle on top of those layers.[7]

Most types of soil are acceptable for use in earthbag construction and a precise ratio is not required.[10][9] A typical ratio is 25-30% clay, 70-75% sandy soil, 10% moisture.[10][9] This is very similar to the mixture used in other earthen building systems like adobe, cob and rammed earth.[5]

Clay is required to bind aggregates together.[10] If the soil does not contain enough clay (minimum 20%),[7] more clay may need to be brought in. Alternatively, cement can be used as a stabilizer, added in a 10% mix. A mix with over 30% clay may be unstable,[3] must be kept dry to handle, and may slump if it becomes too moist.[9] High clay content soil is also harder to dig and to fill into bags.[10]

The superadobe and hyperadobe methods utilize adobe earth as a fill material. With regards superadobe, the contents of the bags settles into its permanent form within 3 days.

Barbed wire[edit | edit source]

Use heavy duty (e.g. 14 guage) 4-point barbed wire.[7][8] Galvanized wire is also available. The barbed wire acts like mortar (or glue) between courses, locking them together. It adds tensile strength to the structure (resisting lateral forces and outplane forces). Barbed wire resists outward expansion caused the load of the rest of the wall from above.[8]

Barbed wire is not used in hyperadobe, because the gaps in the mesh allow the filler material from one course to blend with the courses above and below, thus creating a monolithic structure of continuous adobe.

Gravel[edit | edit source]

Gravel is used for french drains and for foundation courses. Sharp stones, such as the type used for road surfacing, may rip bags.[7] Larger stones can be used in the lower parts of the foundation.[7]

Rebar[edit | edit source]

Mild steel bars 12mm: Conforming to NS 84-2042 or IS:432-1966 (Part I) with fy = 250 N/mm² (Fe250 Grade).[8] Rebars can also be painted with anticorrosion agent.[8]

Nails[edit | edit source]

8 cm nails are useful to pin down corners of bags.

Tools[edit | edit source]

- Digging tools: Shovels, picks, rods

- Tamping tool

- Bricks/weights

- Buckets

- Hose

- Slider (sheetmetal or plywood)

- Pliers

- Ladder

- leveling board

- Hoes

- Rubber mallets

- Sieves

- Wheelbarrows

- Hacksaw blade (good quality)

- Hacksaw frame

- Saw

- Trowel

- Sand paper

- Screw driver

- 2 inch round metal pipe (used as a "roll" for polythene tube, mesh or barbed wire).

- Spirit level

- Sledge hammer

- Wire cutters

- Safety gloves

- Tarpaulin

- Tape measures

- Rope

Tamping tool[edit | edit source]

Most people use a custom tool for tamping the bags. This is a vertical pole with a very heavy, horizonal flat end. It is repeatedly dropped on to each course from above, which results in a horizontal flat surface, and compacts the filler material inside the bag while it is still damp. Welded metal is probably the best material for the tamper. One author reported failure of a tamper with a cement end.[7] Side tampers can also be used.[8]

Slider[edit | edit source]

Bag holder[edit | edit source]

This is a free-standing frame which holds bags open, allowing them to be easily filled by one person. They can be made from wood.

Measuring container[edit | edit source]

This is useful as it allows for uniformity of filler material per bag, or per section of tube. Uniform volume of filler material per per bag / tube section maintains regular dimensions of the wall. 2-5 kg size tubs/pots, or 5 liter bottles (with top removed) can be used.[7]

Site and design considerations[edit | edit source]

Earthbag buildings should not be built on slopes of greater than 15%.[8] They should not be be on the edge of cliffs or drops unless there is rocky foundation, or hard or medium soil.[8] Poor sites also include riverbanks or waterlogged areas, and areas susceptible to landslides.[8]

Curved walls are generally stronger than straight walls, with circles being the strongest design.[7] Straight walls benefit from buttressing every 12 feet (3.65 meters).[8] Square corners benefit from buttressing also.[8] Buttresses are recommended to be no less than 3 feet (1 meter) long.[8]

Width of windows and doorways are recommended to be no more than 5 feet (1.52 meters).[8] No doorway or window should be closer than 3 feet (1 meter) to a corner (as measured on the inside of the wall).[8] The ideal location for doorways or windows is in the center of the length of the wall.[8]

Procedure[edit | edit source]

Comparison of individual bags, tubes (superadobe) and mesh-tubing (hyperadobe)[edit | edit source]

Both solid weave polypropylene tubing and mesh tubing allow for faster building time compared to using individual bags. However, using tubes tends to require a team of people,[5] whereas using individual bags could be done (slowly) by only a few people.

Foundations[edit | edit source]

Walls[edit | edit source]

If the corners of the bags stick out after tamping, they can be folded and pinned to the bottom of the bag.[5] Cover exposed polypropylene to avoid UV damage. Shade cloth can be used.[7]

Plastering[edit | edit source]

Lifespan and physical properties of earthbag structures[edit | edit source]

Lifespan[edit | edit source]

Since the oldest superadobe structure is no older than about 30 years, the lifespan is unknown. However it is claimed that earthbag structures can last for hundreds of years, if the plaster is properly maintained to prevent exposure of the bags.[8] It is expected that at the end of the lifespan, an earthbag building does not leave harmful remains, simply re-uniting with the earth.

Thermal[edit | edit source]

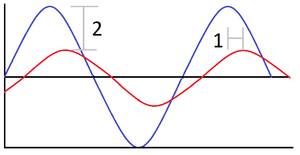

The thermal behaviour of an earthbag structure is closely linked to the nature of the fill material,[5] and also the overall design of the structure. For example a dome would have different thermal properties compared to an earth sheltered design with an earth berm against the earthbag walls. Filler materials which contain a lot of trapped air will act more as insulators, whereas solid and dense fill materials will act as thermal mass. Insulation acts to slow or stop the transfer of heat. Thermal mass absorbs heat and then releases it slowly, like a thermal battery. A building with a lot of thermal mass will tend to have its internal temperature stabilized and moderated, and there will also be a delay as the thermal mass gradually responds to fluctuations in external temperatures. Expressed on a graph, the internal temperature is phase shifted (1) and shows amplitude dampening (2) compared to the external temperature. In simple terms, a building with a lot of thermal mass takes longer to warm up when it is hot outside, and takes longer to cool down when it is cold outside.

Resistance to seismic events[edit | edit source]

Seismic testing has been conducted several times on earthbags structures, and they perform well. Outside of theoretical testing, in 2015 there were 55 earthbag structures in Nepal. A devastating 7.8 magnitude earthquake destoyed many other structures, but all 55 earthbag structures were undamaged.[8]

Flammability[edit | edit source]

Since earth does not burn, it is claimed that these structures are resistant to fire compared to structures built with mainstream techniques. However, other components like doors may be destroyed.

Suitable climates[edit | edit source]

The majority of earthbag structures have been built in hot climates[12] and disaster prone regions.[8] However, this is partly due to the very low tech nature of the method, meaning it has seen wider use in some global regions. In the developed world, building codes are generally stricter, and until fairly recently it may have been difficult to get planning permission or to meet code requirements with earthbag structures.

Overall, earthbag structures are possible in most climates.[7] They are claimed to resist fire, flooding, earthquakes, damp, extreme temperatures, and hurricanes;[7] and are vermin[8] and bulletproof.[7]

In cold climates it is better not to build while the temperature is less than zero degrees Celcius. This is because the water in the filler material can freeze, expand and then the earth may become powdery.[7] Fill material can be altered for cold climates, such as using more insulating material. A seam could be placed along the long axis of the bags, allowing different fill materials to put on the inner and outer sides of the wall. Alternatively, a double layered wall could be used, where the inner wall is earth-filled bags (thermal mass) and the outer wall uses insulation filled bags.[12]

It is possible to build with earthbags during the monsoon, however a tarpaulin is needed to keep the bags dry.[8]

Comparison with other building methods[edit | edit source]

Earthbag building versus mainstream building methods[edit | edit source]

Compared with most "mainstream" building methods, earthbag buildings:

- are easy to construct.[8]

- are cheaper to build.[8]

- may be safer during earthquakes.[8]

- use less manufactured materials, e.g. bricks, blocks, cement, wood, steel.[8]

- require less transportation of building materials, and consequently less use of fuel.[8]

- have less embodied carbon.

- are quicker to build (a team of 10 workers can build a small house in 2 weeks or less).

Earthbag building versus cob[edit | edit source]

Compared to cob buildings, earthbag buildings:

- Are more resistant to floods.[7]

- Are faster to build, but requires more physical strength to lift and tamp earthbags.[7]

- Require more time to finish interiors.[7]

Earthbag building versus straw bale[edit | edit source]

Compared to strawbale buildings, earthbag buildings:

- Are stronger.[7]

- Provide significant thermal mass (strawbale provides more insulation).[7]

- Are more resistant to fire.[7]

- Require more physical strength to lift heavy bags compared to relatively light strawbales.[7]

Projects[edit | edit source]

References[edit | edit source]

- ↑ 1.0 1.1 1.2 History of earthbag building on earthbagbuilding.com by Kelly Hart

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 Building with Earthbags. Joseph Kennedy. 1997 (available on earthbag building.com)

- ↑ 3.0 3.1 3.2 Earthbag Building: The Tools, Tricks and Techniques. Kaki Hunter, Donald Kiffmeyer. New Society Publishers, 1 Jun 2004

- ↑ Building with Unbonded Pumice by Klaus Grasser / Gernot Minke published by Deutsches Zentrum, 1990 (reproduced on earthbagbuilding.com)

- ↑ 5.00 5.01 5.02 5.03 5.04 5.05 5.06 5.07 5.08 5.09 5.10 5.11 5.12 5.13 5.14 5.15 5.16 5.17 5.18 5.19 5.20 Earthbag Architecture: Building Your Dream with Bags. Kelly Hart, Dr Owen Geiger. Hartworks, Inc. 2015.

- ↑ Biography of Nader Khalili on calearth.org

- ↑ 7.00 7.01 7.02 7.03 7.04 7.05 7.06 7.07 7.08 7.09 7.10 7.11 7.12 7.13 7.14 7.15 7.16 7.17 7.18 7.19 7.20 7.21 7.22 The Mud Earthbag Building. Atulya K. Bingham. 2015.

- ↑ 8.00 8.01 8.02 8.03 8.04 8.05 8.06 8.07 8.08 8.09 8.10 8.11 8.12 8.13 8.14 8.15 8.16 8.17 8.18 8.19 8.20 8.21 8.22 8.23 8.24 8.25 How to Build an Earthquake-Resistant Home: An Earthbag Construction Manual. Engineering for change. 2018.

- ↑ 9.0 9.1 9.2 9.3 9.4 9.5 9.6 Earthbag Technology - Simple, Safe and Sustainable. Owen Geiger, Kateryna Zemskova. Nepal Engineer's Association (NEA) Technical Journal. Vol XLIII EC30 special issue on the Gorkha Earthquake 2015 (available on Good Earth Nepal website)

- ↑ 10.0 10.1 10.2 10.3 10.4 Earthbag Building Guide: Vertical Walls Step-By-Step. Owen Geiger. 2011 (ebook/pdf download)

- ↑ 11.0 11.1 11.2 Earthbagbuilding.com homepage

- ↑ 12.0 12.1 Earthbag Building in Cold Climates. Dr. Owen Geiger.

Further reading[edit | edit source]

Books

- Earthbag Building: The Tools, Tricks and Techniques. Kaki Hunter, Donald Kiffmeyer. New Society Publishers, 1 Jun 2004

- Earthbag Building Guide: Vertical Walls Step-By-Step. Owen Geiger. 2011 (ebook/pdf download)

- Earthbag Architecture: Building Your Dream with Bags. Kelly Hart, Dr Owen Geiger. Hartworks, Inc. 2015.

Websites

- EarthbagBuilding.com: Sharing information and promoting earthbag building (website of Owen Geiger and Kelly Hart)

- CalEarth.org The California Institute of Earth Architecture

- Step-by-step earthbag building by Owen Geiger on Instructables.com

- Good Earth Nepal

- Earthbag building on Precision Structural Engineering website

Videos