The Campus Center for Appropriate Technology contracted our team, The ECO-PLUMBERS through Engineering 215 Intro to Design at Cal Poly Humboldt in order to design a filtration system that would remove the particulate matter from their kitchen sink and improve the functionality of CCAT's greywater marsh. To accomplish this, Team ECO-PLUMBERS used the five phases of the design process shown below:

- Project Formulation

- Problem Analysis and Literature Review

- Search for Alternative Solutions

- Decision Process

- Specification of Final Solution

As a result of the design process Team ECO-PLUMBERS designed constructed and implemented The Pizza Box a sustainable filtration device that is safe and effective.

For more information about the design process and about The Pizza Box please view the document we created while designing the filter: ECO-PLUMBERS

Background[edit | edit source]

CCAT is a student run organization dedicated to the practice and teaching of sustainability and appropriate technology. Over the last 31 years, CCAT has demonstrated sustainability and appropriate technology to the students of Cal Poly Humboldt and the surrounding community.[1] One aspect of CCAT's practice of sustainability is their use of a greywater marsh to clean household wastewater to use for the irrigation of their landscape agriculture, and to reduce the amount of wastewater entering city sewage.[2] CCAT's experimental greywater marsh includes effluent from their kitchen sink. Kitchen sink effluent is typically not in greywater systems due to the high amount of particulate matter which decreases the overall efficiency of the system.[3]

Problem statement and criteria[edit | edit source]

The objective of this project is to assist CCAT by improving their greywater treatment system. Team ECO-PLUMBERS designed a particulate filtration system, which is built to remove particulate matter from kitchen wastewater. The design criteria given by CCAT are listed in Table 1.

| Design Criteria | Criteria Constraints |

|---|---|

| Accessibility | The design must be easily accessed to allow for regular maintenance by users of the sink once a day. |

| Maintainability | The design must be simple to clean while in use. Cleaning should take no longer than ten minutes. |

| Durability | The design must be able to withstand regular household use for all users at CCAT for a minimum of five years. |

| Aesthetics | The design must have a pleasant appearance, as it will be seen by all users of the sink at CCAT. |

| Safety | The design must not have any rough or sharp edges that could cause injury. The design must not allow for bacterial growth within the mechanism. |

| Effectiveness | The design must be able to handle a constant water flow of sink water at a rate of 2.26 gallons per minute and remove solids greater than 1/16 of an inch. |

| Cost | The design must not cost more than 325 dollars. This value is based on 100 dollars provided by the client and 75 dollars per group member. |

Description of final project[edit | edit source]

Photos and descriptions[edit | edit source]

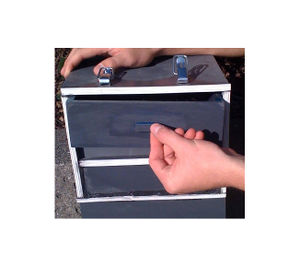

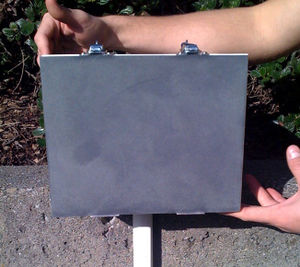

The Pizza Box, shown in Figure 1 and Figure 2, is a greywater filter designed to remove particulate matter from CCAT's kitchen sink effluent. The Pizza Box consists of two main parts; the coarse filter that removes particles larger than 3/16 inch and the fine filter that removes solids larger than 420 microns. The body of the filter is constructed from 3/8 inch PVC glued together using PVC cement and primer. The Pizza Box is seven and one half inches tall and ten inches square. There are two stainless steel hinges that connect the door of the filter to the frame. The seal for the door is made from foam-rubber stripping that is reinforced with silicone gasket gel. Two catch-and-draw latches located on top of the filter body provide the needed force to create a water-tight seal between the door and the filter body.

Sink effluent may escape the filter during cleaning when the user opens the door and removes the filters. To counter the escape of sink effluent, The ECO-PLUMBERS designed the location of the door hinges at the bottom edge of the frame. This door location allows the open door to catch effluent as it drips from the removed filter, thus minimizing mess during cleaning.

The interior of the frame is lined at the bottom with fiberglass resin, as shown in Figure 20, to create the needed funnel shape necessary to allow water to properly drain from the mechanism. When both filters are removed, wastewater may still be passed through the device, but will enter the greywater marsh without filtration.

The weight of the device is 20 pounds and therefore requires a support to prevent excessive stress on the plumbing fixtures. A table-like support was constructed to provide the necessary supports to hold The Pizza Box in place during use and maintenance. The supporting table has a 3/8 inch PVC shelf supported by four aluminum legs. The legs are attached to the shelf by stainless steel screws that are easily removed for adjustment.

Costs[edit | edit source]

Implementation costs are a total of all parts needed to construct The Pizza Box. To show a cost analysis of savings the team expense was compared to the current market value, shown in Table 2, of all the parts needed for material and construction. Team ECO-PLUMBERS spent a total of $203.23 on the materials for the final design, which is a savings of $48.90 from the current market value. The current market standard value of each item listed in Table 2 shows the potential price our team could have spent if we had bought all the parts at current market price.

| Materials | Quantity | Price Per Item | Team Expense | Current Market Cost |

|---|---|---|---|---|

| 24"x48" Plastic PVC | 1 | 71.98 | 71.98 | 71.98 |

| 1.5" PVC Shut Off Ball Valve | 1 | 12.95 | 12.95 | 12 95 |

| Catch and Draw Hinges | 1 | 6.49 | 6.49 | 6.49 |

| Gasket Sealant | 1 | 6.99 | 6.99 | 6.99 |

| Rubber Weather Strip | 1 | 5.99 | 5.99 | 5.99 |

| Bottle PVC Glue | 1 | 6.49 | 6.49 | 6.49 |

| Stainless Steel Hinges | 1 | 7.49 | 7.49 | 7.49 |

| Resin Fiberglass Bondo | 1 | 10.99 | 10.99 | 10.99 |

| Foam Greatstuff 12oz | 1 | 3.99 | 3.99 | 3.99 |

| Fiberglass Cloth | 1 | 7.49 | 7.49 | 7.49 |

| Wall Anchors | 16 | 0.10 | 1.60 | 1.60 |

| 80 Grit Coarse Sandpaper | 1 | 1.59 | 1.59 | 1.59 |

| Hardware Stainless Steel Screws | 22 | 0.15 | 3.30 | 3.30 |

| Paintbrush | 2 | 0.59 | 1.18 | 1.18 |

| 180 Grit Fine Sandpaper | 1 | 0.95 | 0.95 | 0.95 |

| Miscellaneous Plumbings and Fittings | 1 | 28.48 | 28.48 | 28.48 |

| Stainless Steel Fine Filter | 1 | 30.00 | Donated By The Tofu Shop | 30.00 |

| Polycarbonate Thermoplastic | 1 | 32.35 | Donated By Marty Reed | 32.35 |

| Purple Primer for PVC | 1 | 3.06 | Donated By Marty Reed | 3.06 |

| 1- Purple Primer for PVC | 1 | 71.98 | 3.06 | 3.06 |

| Stainless Steel Straping | 1 | 9.36 | 9.36 | 9.36 |

| Tax | 15.92 | 21.43 | ||

| TOTAL | $203.23 | $252.13 |

Discussion and next steps[edit | edit source]

The Pizza Box filter sufficiently filtered greywater from the sink at CCAT. The Coarse Filter successfully removed large particles while the Fine Filter removed smaller particles. To ensure long-term proper functioning of the Pizza Box, regular cleaning of the device is required. Instructions for use and maintenance is posted near the kitchen sink at CCAT, and an instructional video is available on YouTube. If long-term use of the filter shows that frequent clogging may occur, a small tap may be installed on the wall of the device to allow for drainage during cleaning. If leaking occurs after prolonged use, the door seal may need to be repaired or replaced. As with any piece of functional hardware, general checks on the integrity of the frame, filters, and plumbing must be performed to account for unexpected malfunctions.

References[edit | edit source]

- ↑ CCAT (2009). "Campus Center for Appropriate Technology." <http://web.archive.org/web/20100702004636/http://www.humboldt.edu:80/~ccat/about.php> (Sept. 30, 2009).

- ↑ Payne, Lynsey, Medina, S., and Ebright, T. (2009). "CCAT greywater marsh (current)." L. Grafman, ed. <https://www.appropedia.org/CCAT_greywater_marsh_(current)> (Sept. 30, 2009).

- ↑ Ludwig, Art (2009). "The Common Greywater Error and Preferred Practices." <http://www.oasisdesign.net/greywater/misinfo/index.htm> (Sep. 30, 2009).