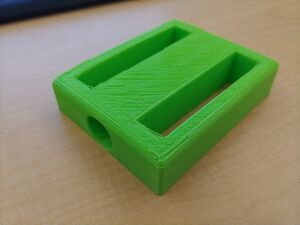

My goal was to create a printable item that would be useful in many regions and I realized that in many countries people rely on bikes. Biking is made much easier and more comfortable when the bike has large flat pedals. Bike pedals can cost much more than some people live off of daily in certain developing nations. The pedal is intended as a usable substitute for a factory bike pedal, though not totally equivalent. OEM components may not be available in certain countries so this pedal may be useful in countries that have access to 3D printing technology, yet do not want to spend the money/ do not have the time to wait months to get an essential part to an essential part of their daily life.

Bill of materials[edit | edit source]

- This part was printed from PLA filament which can cost about $16 a kilogram and this pedal uses about 53 grams of filament. This puts the cost of a pair of pedals under $3.00.

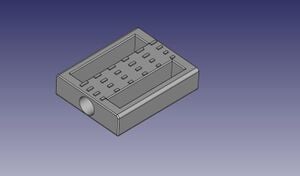

- FreeCAD and STL files: File:Bikepedal.FCStd

Tools needed[edit | edit source]

- Jellybox or similar RepRap 3-D printer or similar

- Filament

- Pedal Spindle for example this pedal spindle [1]

Skills and knowledge needed[edit | edit source]

- This link contains some useful information: [2]

Technical Specifications and Assembly Instructions[edit | edit source]

- To achieve a similar result as the picture, use 1.75mm PLA filament

- The print should use about 50g of filament

- Print time is longer than 3 hours

- The spindle should be no larger than.7 inches in diameter

Common Problems and Solutions[edit | edit source]

- For best results, slow the print time.

Cost savings[edit | edit source]

- This part saves at like $7, potentially more.

- I estimate the electricity usage to have been about $0.08 for the print.

- Commercial equivalent: [3]

- My solution is 70% less expensive.