| Line 41: | Line 41: | ||

==References== | ==References== | ||

<references/> | <references/> | ||

Revision as of 15:20, 4 December 2014

Micro-Turbines for Water Power

Project developed by Emily Hunt

Template:Statusboxtop Template:Status-design Template:Status-prototype You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Abstract

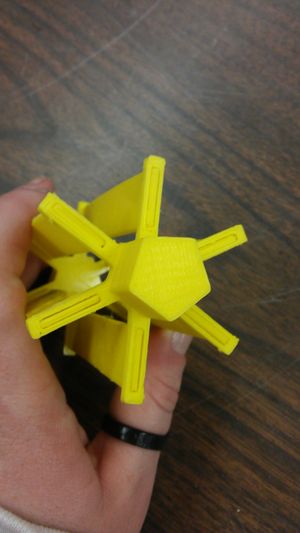

This is a cross-flow turbine[1], essentially a water wheel turned by naturally flowing water to produce energy. Unlike a dam, or a mill wheel this is very small, more used in smaller streams and such. This provides energy without the cost of fuel and the only time and energy used to work on it is set up and very occasional maintenance. This is used in developing areas around the world because it's much cheaper and less time consuming. This design takes it to the next level where the material costs of the wheel itself are significantly reduced using 3D-printing.

Bill of Materials

- PLA or ABS Filament (1.75mm)

- All of the STL files and the SCAD files are here.

- Plastic Epoxy for better blade adhesion.

- Hook up to actually generate power

Tools needed for fabrication of the OSAT

- MOST Delta RepRap or similar RepRap 3-D printer

- Knife/Exacto Knife

Skills and Knowledge Necessary to Make the OSAT

- 3D-printing

Technical Specifications and Assembly Instructions

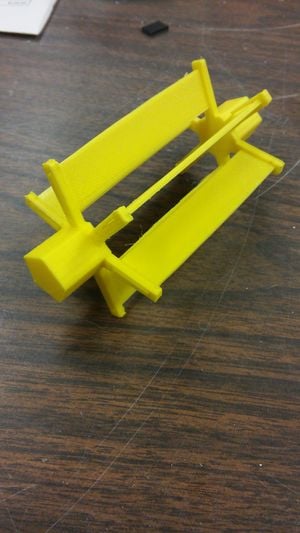

- Slide the blades into the slots so the wheel handles are facing out.

- if friction isn't sufficient to hold the blades then add a small amount of epoxy onto the inside of the wheel on the blades for more secure fit.

Common Problems and Solutions

- Poorly fitting blades, or broken wheel spokes are both fixable with a small amount of epoxy

Cost savings

- The mini wheel is about $0.30

- Cost saving really depend on the size of the wheel.

- Some micro-turbine plants can cost up to $2000.

References

- ↑ Wikipedia: Cross-flow turbine Available: http://en.wikipedia.org/wiki/Cross-flow_turbine