Team Fab Four joined together in Spring of 2023 to design a renewable system that would deliver warm water to students at Trillium Charter School (Arcata, CA). We worked with our client, Katie Dens, at Trillium in order to implement a solution that would best serve the desired consumer, students from grades three through five.

Background[edit | edit source]

Team Fab Four is part of the Introduction to Design (ENGR 215) course located at California Polytechnic University, Humboldt. Every semester, students team up and engage with a client that has a proposed problem or request. At this sustainability focused k-5, students wash their hands in an outdoor water dispenser that they fill at 10 and 12 A.M, prior to eating. With no proper drainage, this water splashed on the ground beneath the dispenser, oftentimes soiling their shoes and clothes. Team Fab Four sought to generate a solution that would decrease their reliance on the water dispenser method.

Problem statement[edit | edit source]

The objective of this project is to provide a solar powered hand washing station for Trillium Charter School.

Criteria[edit | edit source]

The criteria below were generated with objective, budget, and the client in mind. They serve as parameters to the project's various design aspects and are accompanied by specifications. These specifications are then weighted to assess for importance.

| Criteria | Description | Weight (1-10) |

|---|---|---|

| Cost | To design, build, and test the price of the entire system must not exceed a budget of $700.00 | 7 |

| Functionality | The system must be able to provide hand washing water with adequate pressure, temperature, and volume. | 10 |

| Sustainabiliy | The system must be assembled with material that is upcycled, repurposed, second hand, and non-toxic. | 7 |

| Durability | The system must be built to withstand local weather conditions for prolonged periods of time. | 10 |

| Safety | The system must follow temperature, pressure, and water safety regulations, including securing external components that may pose a risk to children. | 10 |

| Educational value | The system must provide a learning opportunity to those who use it. | 6 |

| Consistency | The system must provide warm water and run smoothly every time it is used. | 10 |

| Output level | The system must provide a minimum of two to three gallons of water per day. | 7 |

| Aesthetics | The system must be visually appealing to the consumer. | 7 |

Prototyping[edit | edit source]

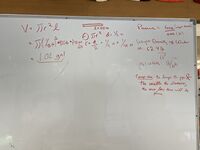

Next, the project required prototyping. In its earliest development, this involved performing calculations regarding volume and angles. A cardboard scale model was then crafted to get an idea of the layout. These proved useful towards more high stakes prototypes, like the solar collector depicted below.

- Prototyping

-

Image of a volume calculation. This involved inputting the radius and length of tubing to determine output in gallons.

-

Image of a scale cardboard model of the entire system on location.

-

Image of first prototype of solar collector. Features 100 feet of 1/2" diameter PEX tubing painted black and covered with an acrylic panel in a 33" x 33" box.

-

Image of Sketchup design. Features rough dimensions the sink and solar collector.

Final product[edit | edit source]

The Solar Warm Water Sink uses solar radiation from the sun to warm water that runs through tubing which is then dispensed as needed by the students. It features two main components, the solar collector and the sink.

Solar collector

In the solar collector, there were two main building aspects: the construction of the wooden stand and the solar collector itself. The stand the solar collector sits on top of is built with pressurized wood to increase its durability as it is exposed to the elements. The stand is tall enough to achieve optimal sun during winter which is around three to four feet and will be facing Southeast to follow the path of the sun. The stand is also built to support the weight of the water in the solar collector, which holds approximately 1 1/2 gallons of water in total.

The solar collector features a 36" x 36" wooden box that holds black PEX tubing in place with a polycarbonate roofing panel for heat capture. The panel, black painted tubing, and foam insulation with wooden cover pieces best create a greenhouse effect while being suitable for kids to be around. The wooden box has approximately 100 feet of ½" PEX tubing arranged in a spiral with two exits on both sides of the wooden collector. For the inlet and outlet, a ¾" hole was drilled and allowed for the tubing to pass through. The wooden box is tilted at a 40° angle for optimal solar radiation with respect to Arcata's position relative to the sun. This angle was calculated for optimal solar capturing averaged for the course of a full year.

Sink and Piping

Piping runs between the water source, solar collector, and sink in order to finally deliver warm water to a faucet. ½" in diameter PEX tubing was applied throughout the system. At the spigot on location, a ¾" split valve was attached. This allows for the previous hose, used for watering plants for instance, to still be in use when desired, while the other hose serves as a water source for the solar warm water sink. The hose water then travels to a second split valve at the sink that divides the flow from the hose to two PEX tubes. The hose is connected to PEX with a SharkBite splitter (¾" to ½"). One tube delivers water to the cold water inlet with a shark bite connector at the faucet so that temperature regulation can occur by mixing cold and hot water to produce warm water. The other tube runs water to the solar collector so that it can pass through the coils to be heated by the sun. Finally, the heated water exits the solar collector with more PEX tubing and is connected directly to the hot water faucet with another shark bite connector. The water in the sink drains to a bucket placed in the cabinetry underneath, a method that allows the water to be repurposed.

Construction[edit | edit source]

- How to make the System

-

Obtain a 36" x 36" piece of plywood. Obtain 4 2" x 4" pieces of wood, cut to size, and drill them together to create a frame. Attach frame to plywood by drilling.

-

Obtain 100 feet of 1/2" diameter PEX tubing. Coil the tubing within the 36" x 36" box. Secure the coil with wooden dowels in an X Position. Drill the two 3/4" holes on opposite sides of the box to allow for the tubing to enter and exit the box.

-

Obtain 4 4" x 4" pieces of wood that are 4 feet tall. Secure these four posts together by screwing 4" x 4" 28" long between each post. *Be careful to make sure the ground on which you are drilling is completely flat.

-

Obtain an additional piece of 36" x 36" piece of plywood. Place it on top of the stand. Drill it into the posts to secure it.

-

Obtain black acrylic-based spray paint. Spray the coiled PEX tubing within the box with this spray paint.

-

Obtain a greenhouse panel. Cut it to 36" x 36" to place on top of the box. Screw it into place.

-

Obtain two 2" x 4" pieces of wood. Cut it to the desired angle that you wish the solar collector to stand at. Drill these into place and into the solar collector in order to prop it up. At the front of the stand, another piece of 2" x 4" in cut to size and drilled to the platform to stop the solar collector from sliding forward.

-

Obtain spray foam insulation. Apply it as needed to secure gaps.

-

Obtain two additional pieces of wood. Cover the foam insulation with this wood.

-

Obtain an additional split valve. Attach the hose to the split valve. Attach two pieces of PEX tubing to both outlets on the split valve using a SharkBite connector. One PEX tube should run be connected to the PEX tubing at the solar collector the other should run to the cold water inlet at the faucet.

-

Attach the PEX tube on the split valve the cold water inlet on the faucet. Attach the other PEX tube that arrives from the solar collector to the tot water inlet on the faucet.

-

Ensure that there are no leaks by attaching Teflon tape to the threads of the SharkBite connectors that connect PEX to PEX. Cutting the tube at an angle at these connection spots also eliminates leakage.

Team Fab Four Project Process[edit | edit source]

Below is a video demonstrating the building process, operational instructions, and why this project matters.

Bill of materials[edit | edit source]

The total cost was $479.50 for the construction of prototypes and the final product. See the cost breakdown in the tables below:

| Item | Amount | Cost per unit | Total |

|---|---|---|---|

| Split Valve | 1 | USD 13.98 | USD 13.98 |

| Greenhouse sheet | 1 | USD 30.99 | USD 30.99 |

| 5" Screws | 20 | USD 0.35 | USD 6.99 |

| 3/4" Drill Bit | 1 | USD 4.49 | USD 4.49 |

| 3/4" to 1/2" F brushing | 1 | USD 6.99 | USD 6.99 |

| Corner brace | 1 | USD 6.99 | USD 6.99 |

| Paint Brush | 1 | USD 1.69 | USD 1.69 |

| Sink Vanity | 1 | USD 30.00 | USD 30.00 |

| Black Spray Paint | 2 | USD 8.59 | USD 17.18 |

| Electrical Tape | 1 | USD 7.30 | USD 7.30 |

| Foam Pipe insolation | 1 | USD 2.51 | USD 2.51 |

| Shark bite connector 1/2" to 3/4" F | 1 | USD 11.99 | USD 11.99 |

| Rachet Cutter | 1 | USD 15.99 | USD 15.99 |

| Spray Foam | 1 | USD 7.49 | USD 7.49 |

| Sink Faucet | 1 | USD 39.99 | USD 39.99 |

| Shark Bite 1/2" connector F | 1 | USD 7.79 | USD 7.79 |

| Shark Bite disconnector | 1 | USD 2.59 | USD 2.59 |

| Pex Couple 1/2" | 3 | USD 8.49 | USD 25.47 |

| Hose adapter | 2 | USD 6.49 | USD 12.98 |

| Foam Pipe insulation | 1 | USD 1.79 | USD 1.79 |

| Shark bite 1/2" connector M | 2 | USD 8.49 | USD 16.98 |

| Teflon Tape | 1 | USD 1.79 | USD 1.79 |

| Split Valve | 1 | USD 6.99 | USD 6.99 |

| Pex tubing 1/2" 130ft | 1 | USD 59.92 | USD 59.92 |

| Hose 15ft | 1 | USD 12.99 | USD 12.99 |

| Spray varnish | 1 | USD 15.99 | USD 15.99 |

| Grand total | USD 353.86EUR 304.32 <br />GBP 258.32 <br />CAD 438.79 <br />MXN 7,377.98 <br />INR 26,486.42 <br /> | ||

| Item | Amount | Cost per unit | Total |

|---|---|---|---|

| Lumber (4"x4"x4") | 4 | USD 10.56 | USD 42.25 |

| Lumber (4"X4"x2.3") | 4 | USD 7.56 | USD 30.25 |

| Lumber (2"X4"X10") | 2 | USD 8.67 | USD 17.34 |

| Lumber (4'X8') cut into 36"X36" plywood | 2 | USD 17.90 | USD 35.80 |

| Grand total | USD 125.64EUR 108.05 <br />GBP 91.72 <br />CAD 155.79 <br />MXN 2,619.59 <br />INR 9,404.15 <br /> | ||

Operation[edit | edit source]

Run water through system once (water should exit faucet with hot water handle), then turn off water flow to trap water. For the warmest water, it is advised to turn the water on and then off at least 45 minuets before warm water is needed. This is variable depending on weather.

Dispense water from the faucet as needed. In direct sunlight, the solar collector will produce hot water, meaning cold water from the faucet will have to be turned on in conjunction to produce warm water.

Maintenance schedule[edit | edit source]

Below are recommended maintenance protocol for the system and their frequency.

- Monthly

- Clean off greenhouse panel with household cleaning supplies to ensure the system receives optimal solar radiation.

- Yearly

- Apply a coat of spray varnish to the solar collector to ensure the it remains weather proof and durable.

Conclusion[edit | edit source]

Testing results[edit | edit source]

Two tests of the solar collector and sink were conducted in different weather conditions. First condition was cloudy weather with a outside temperature of 51°F. The initial temperature of the water was 51°F before running through the solar collector. After the water was within the system for 20 minutes, the water reached a temperature of 64°F. The second test was in partly cloudy weather with a outside temperature of 63°F. With a initial water temperature of 51°F after running the system for 45 minutes the water reached a temperature of 90°F.

Discussion[edit | edit source]

When it is cloudy, the solar collector does not warm the water to a degree in which mixing cold water for temperature regulation is required. However, when the solar collector is in direct sunlight, the warm water produce is more than adequate for washing hands. Adequately warmed water can be achieved in many conditions so as long as it is left to warm in the solar collector for the required amount of time.

Lessons learned[edit | edit source]

Prototyping taught team Fab Four that water based black paint will not remain on PEX tubing and rather peel and chip off completely. Instead of prototyping on a large scale, paint could have been applied to a small piece of PEX tubing to test its viability. Improvements were made to the prototype solar collector by adjusting the size of the box to fit all the tubing and using different a greenhouse panel instead of acrylic sheet to better capture heat. Finally, a larger solar collector with more piping within it would solve the potential for warm water to run out too quickly, as the dimensions limit the output level of the system.

Troubleshooting[edit | edit source]

| Problem | Suggestion |

|---|---|

| Leaks in piping | Make sure PEX connectors are securely attached / apply Teflon tape to groves in connectors. |

| Water isn't flowing threw the collector | Ensure that the split valve is open to the PEX that is connected to the solar collector (split valve is located on the back side of the sink). |

Team Fab Four[edit | edit source]

Introduce team and semester in the following format:

References[edit | edit source]