The Write On! paper press is a paper pressing tool that was designed for Trillium Charter School to make their own paper using blended, recycled materials. Trillium Charter, a local school in Arcata, CA, wanted a fun and accessible way for their students to make paper. This project was created for an engineering class, ENGR 215-Intro to Design at Cal Poly Humboldt. It was made my our team, Write On! including members Jess Hill-Roddick, Rose Nicholson, and River Patla.

Background[edit | edit source]

The focus of this project is to create a functional paper press which can be easily operated by children and create paper which is usable and writable. The client is Trillium Charter school, a small elementary school consisting of grades kindergarten through fifth. Trillium is located in Arcata, California and is currently operating in a large home a mile away from Cal Poly Humboldt campus. The school has four main values all surrounding respect, these include respecting the community, one another, the environment, and themselves. Engineering 215, introduction to design is a course which revolves around many of the same values as Trillium. The course is a true introductory class which allows students to struggle, grow, and learn at the hands of their own designing process.

The course allows students to get a taste of real engineering design while solving a real client problem. For many students, it is their first time engineering something which will be used in the real world. Write On! is a group of environmental engineering women with interest in serving the community to solve issues.

Problem statement[edit | edit source]

The objective of this project is to design, build, and test a paper press which creates writable, functional paper with little effort.

Criteria[edit | edit source]

There are eight criteria/constraints for this paper making project. The table is weighted on a scale from 1-10. 10 meaning it is extremely important, and the project must hit that specific criterion; 1 meaning the criteria is unnecessary.

The three most important criteria for the client are the usability of the paper making tool, the paper quality this tool produces, and the safety of the product. This is being made for children so it must be simple enough for a kid as young as 7-8 to be able to use it without problems. The paper making tool is expected to bring about paper that one can use. The client wants the students making the paper to be able to write letters to their numerous pen pals in Taiwan and Brawley, CA. This tool must be safe for children to use. There should be no injuries while using this product.

| Criteria | Description | Weight (1-10) |

|---|---|---|

| Usability | Children can use easily | 10 |

| Paper Quality | Writable, depedendable | 10 |

| Safety | No injuries | 10 |

| Durability | Lasts 5-10 years | 8 |

| Cost | Less than $700 | 8 |

| Portability | Can be moved easily | 8 |

| Educational Value | Children gain hands on experience | 8 |

| Embodied Energy | Less than 1/3 materials purchased new | 6 |

| Aesthetic | More than 1/2 of children and staff enjoy appearance | 5 |

Prototyping[edit | edit source]

When beginning the prototyping phase we took inspiration from a simple press design. While drawing our different design ideas on paper we came up with the idea to add a drainage system to create a more sustainable and unique paper making press. We first settled on a funnel like drainage system that would allow the water to flow down into a smaller container under the press. When prototyping this we realized that the funnel like structure would give no support to the mesh on the mesh frames when being pressed on. So, we came up with a new design that would allow water to drain while also keeping the integrity of the mesh intact. This design consists of an indent in the bottom piece where the mesh frames will sit and rows of holes inside the indent where the water will drain.

Final product[edit | edit source]

Our final product is a paper press that is easy to use, and makes usable paper. The pulp (water and recycled paper/materials blended) sits on a 8.5” by 11” mesh frame. The press screws down using a zinc-plated rod attached to a hand wheel. As the press reaches the bottom, it hits the mesh frame, allowing the pulp to be pressed down creating level, writable paper. As the water drains through the holes, it drips into the pan underneath the base of the press allowing the water from the pulp to be saved and reused for the next round of pulp.

Construction[edit | edit source]

The Paper Making Press took a surprisingly long amount of time and effort to build. We started by prototyping the press with cardboard and tape. During this process we were able to come up with a water drainage design that will help our client and their students collect excess water from the pulp and reuse it.

Bill of materials[edit | edit source]

The total cost was $388.85 for the construction of prototypes and the final product. See the cost breakdown in the table below:

| Items | Price |

| 14 Aralack 1’’ ACX Arauco (wood) | $47.11 |

| Arm n Seal Finish | $19.96 |

| Brushes | $4.58 |

| Hand Sand Pad | $4.24 |

| Metal Rod | $4.48 |

| Wood Screws 1’’ | $16.09 |

| Flanges | $45.83 |

| Rotary Handwheel | $22.49 |

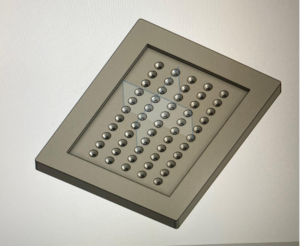

| Metal Screen Door Mesh | $10.99 |

| Rods | $21.56 |

| 2x2 yellow pine | $2.99 |

| Screen door mesh | $0.00 |

| Scrap wood | $0.00 |

| 1x2 inch wood | $1.99 |

| Metal Mesh | $9.99 |

| Jigsaw | $43.11 |

| Tee Nut | $5.99 |

| Pillow Block Bearing | $16.25 |

| Staple Gun | $16.99 |

| Staples | $3.99 |

| JB Weld | $9.99 |

| Plastic gloves | $29.99 |

| ⅝ nut x2 | $2.46 |

| ⅝ inch stop nut | $1.23 |

| ¾ foot Flange | $9.99 |

| Coupling nut | $6.99 |

| 36-inch ⅝ pitch metal rod | $8.99 |

| Stainless Steel Furniture Legs | $6.99 |

| Silicone Tray | $13.59 |

| Total Cost |

|---|

Conclusion[edit | edit source]

Testing results[edit | edit source]

When testing the Paper Making Press, it was able to make well pressed flat paper. Enough pressure was applied to the pulp and the water in the pulp drained into the catchment system.

Troubleshooting[edit | edit source]

| Problem | Suggestion |

|---|---|

| Hand Wheel does not rotate | Use WD-40 and grease up metal components |

| Frames do not fit in indent | Make sure mesh frames are lined up with the correct sides (one is 8.5” and the other 11”) |

| Will not push down all the way | Make sure metal rod and shaft collar is clean and free of pulp that may be stopping it |

Team[edit | edit source]

Team: Write On! Spring Semester 2023

- Jess Hill-Roddick

- Rose Nicholson

- River Patla