The Greywater Island project is a proposed Greywater treatment system for the Samoa Cookhouse and Hostel. As part of the sustainable operations of the Hostel, the greywater island functions as the largest implemented greywater treatment system in the restored facility. The greywater system was specifically designed under a criterion that would fulfill California state water quality standards, generate optimal functional capacities and require minimal maintenance and cost. the implemented greywater system was rendered by means of a custom made sizing calculator and graphical models of the design.

Introduction[edit | edit source]

The historic Samoa Cookhouse will be the new host of an alternative lodging hostel where guests can engage in educational modules and experience the features and functions of sustainable design. The renovation of the Samoa Cookhouse hostel became a collaborative project in which Humboldt Bay Center for Sustainable Living and Danco took part to exemplify the resourceful opportunities available by restoring available structures using sustainable principles.

Criteria[edit | edit source]

The underlying foundation for the greywater treatment design was based on the following set of criteria that were formulated to satisfy the client demands, our creative ideals and prescribed safety standards. The formalized list of criteria was established in order of descending focus which stated the following:

- Safety: Operating greywater treatment system must fulfill California greywater quality standards.

2. Functionality: System must treat optimally maximum water load.

3. Maintenance: Require minimum maintenance to maintain optimal performance.

4. Cost: Exceed no more than $75 allowed per student.

5. Biodiversity: Create a sheltering landscape to attract biodiversity.

Greywater Treatment Design[edit | edit source]

Pretreatment[edit | edit source]

Greywater produced inside the Hostel is routed through new 4" piping and exits the building parallel to the existing backwater sewage lines in the south rear of the building. Treatable greywater sources include the wastewater from the upstairs bathroom sinks, showers, and laundry washing machines. The new greywater lines and the blackwater lines are separated by a three way diverter valve. This valve allows an operator to divert greywater for treatment in the system or handled as backwater and sent through the existing sewage lines.

Primary Treatment[edit | edit source]

The direction of water flow is clearly marked for safety purposes. Flow will need to be diverted for reasons including: seasonal marsh flooding, maintenance, and emergency services. Greywater which will be treated by the system passes the three way valve and flows into an 8000 Liter septic tank converted into a settling tank. The tank is located away from the paths of maintenance vehicles, existing plumbing, emergency water lines, and is easily accessible when service becomes necessary. The purpose of the tank is to provide optimum conditions for the settling and retention of suspended solids in the greywater. This is a physical treatment process. The settling tank regulates flow producing uniform effluent. Tank sizing accounts for surge conditions and is capable of treating the maximum load of the building. Greywater retention time in the settling tank is less than 24 hours as per California Code. Water leaving the settling tank is routed between the ground and the first floor of the Samoa Cookhouse. This under floor space allows for optimum grading and promotes better flow for a more effective system. The water from the settling tank is routed directly into the Horizontal Flow Constructed Wetland.

Secondary Treatment[edit | edit source]

Filtering of F.O.G follows secondary process that allows for further removal of contaminants by means of biological filtration. Nutrients are absorbed and decomposed by sequential filtering processes accommodated by planted macrophyte roots. Water is directed away from the tank and into the subsurface wetlands through a 4-in pipe to allow maximum flow. Water percolates through gravel and sand down an established decreasing grade of 1in/ft across a length of 24ft on the horizontal bed. Retention time allowed for the treatment is an approximated by the sizing calculator to be 3.5 days for a maximum load of 3,257 gallons a day.

Effluent[edit | edit source]

As the water exits the subsurface marsh, it is leeched out to the surrounding area. Once leaving the marsh the effluent will be within the legal standards for the constituents in the water. BOD and other constituents will be significantly removed and once the water enters the leach field a 300 ft layer of sand will contribute to further removal of BOD, Nitrogen, Phosphorus, and TSS. The leach field is also oriented to meet all greywater standards for greywater discharge. The leech field will be farther than 5 ft from any buildings and at least 100 ft from any lakes or streams. The effluent will also be 100 ft from the public water main. The location of the leech field will also be optimal for filtration of the effluent because of the 300 ft layer of sand.

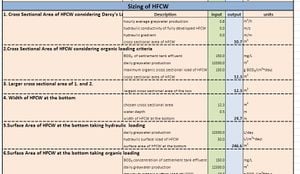

Sizing Calculator[edit | edit source]

As part of the final design of the greywater system, we created a calculator used to size the component of the system. The calculator takes into account water usage, water quality, tank and wetland sizing. The calculator was used for specific sizing of the Samoa Hostel system, however, by changing the parameters, its can be adapted to almost any greywater system of this type.

To view and acquire more information on sizing calculator click here.

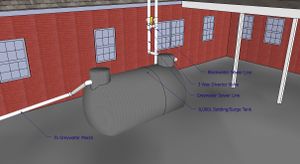

3D Cookhouse Model[edit | edit source]

3D model depicting installed greywater system at Samoa Hostel. This model includes the Hostel building, settling tank, constructed wetland, and other components of the system.

- 3D Model 3D model available for download at Google 3D Warehouse.

- Model in Google Earth (model pending approval for placement in Google Earth)

Video[edit | edit source]

Implementation Cost[edit | edit source]

The implementation cost of the constructed marsh consists of the cost of materials for the installation. The table presents the materials needed, amount of each, price, source and location of the materials. These materials have been selected based on local availability, environmental considerations, and are best suited to the final greywater system design.

| Material | Amount | Unit Cost | Cost | Source |

|---|---|---|---|---|

| Substrate: Gravel | ||||

| Fine: (0.2-0.4 in) | 26yd3 | $24.00 | $624.00 | Eureka Sand & Gravel |

| Coarse: (2-4in) | 7yd3 | $28.00 | $196.00 | Eureka Sand & Gravel |

| Liner: | ||||

| Recycled Rubber: 45mm, 10x50ft -rolls(42m2roll) | 65 m | $485.00 | $750.00 | North Coast Horticulture |

| Native Soil Slurry | 8.2 yd3 | $70.00 yd | $574.00 | Eureka Sand & Gravel |

| Septic Tank: 1,500 gal | 1,500 gal | $1200.00 | $1200.00 | Internet (various) |

| Hardware: | ||||

| Pipe: 3 5/8" Inside Diameter, 1/2" thickness | 100 ft | $2.91/ft | $291.00 | Internet (various) |

| Wire Mesh: 0.120 Wire Diameter, 77.4 % Open Area | 1 ft2 | $37.24/ft2 | $37.24 | Internet (various) |

| Valves: | ||||

| 3" 3-way valve | 1 | $415.00 | $415.00 | Internet (various) |

| 3" 2-way valve | 3 | $71.47 | $214.41 | Internet (various) |

| Vegetation: | ||||

| Reeds,Bullrush,etc. | ~100 | $0.00 | $0.00 | Potawot Health Village |

| Total | $4301.81 | |||

Next Steps[edit | edit source]

When the proper time arises for the implementation of the greywater system for the Samoa Hostel, the designers will need to make few adjustments to the existing design in order to fully adapt to the exact specifications. Using the developed Excel Calculator, it will be easy to input final values for Hostel greywater production and quickly come up with a proposed size for the Settling Tank as well as the Horizontal Flow Constructed Wetland. Our design proposed a location for the HFCW, but it will ultimately be the responsibility of the site plan designers to appropriately place the Greywater Marsh.