PC104 stacks are commonly used in automation and controls applications which could be a potentially hazardous environment for sensitive electronics

The goal for this project was to create an easily 3D printed, easily modifiable, and fully modular case for a PC104 stack of unknown size.

Design[edit | edit source]

-

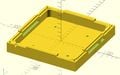

Stack Middle

-

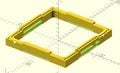

Stack Top

-

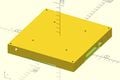

Cable Clamp Base

-

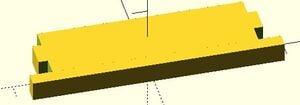

Cable Clamp Top

Variables[edit | edit source]

- Height should be 17mm for a single and 34 for a double height module.

- Keep the outer clearance above 12.7mm to allow room for mating connectors.

- Decreasing wall thickness beyond 10mm may compromise mounting holes.

- The connector holes are stored in an array of an array of parameters. [pins2cablewidth(# pins),cable thickness,side,x offset,y offset]

- side starts at 0 on the ISA bus side and increments as you rotate counterclockwise.

- x offset is from bottom left corner of PC104 module (when the side is facing you).

- y offset is from the center of the case.

Mechanical assembly instructions[edit | edit source]

Remove flashing and push.

Costs[edit | edit source]

| Item | Quantity | Approximate Cost |

|---|---|---|

| Plastic | ~150 grams per section on average | $3.33 |

Current issues[edit | edit source]

- Rendering time is excessive!

- Tab dimensions don't always match on the bottom of the mid section and top

- Clips don't always fit together perfectly

Possible solutions[edit | edit source]

- Simply model & lower resolution

- Fix tab code

- Increase tolerances on clips