Hydraulic wheels or water wheels consist of large wooden or metal wheels, with a number of blades or buckets arranged on the outside rim forming the driving surface.

Impulse Turbines are one of two types of turbines used in hydroelectric power. The impulse turbine is typically used with a head over 10 meters or greater. These impulse turbines also operate under high pressures. The impulse turbine looks very similar to an old fashioned water wheel or river boat paddle.

An impulse turbine has a large number of small "scoops" positioned around a central hub. This central hub would be connected to the generator, thereby producing energy. The large number of "scoops" allows for the turbine to spin at very high speeds. To view various types of impulse turbines please view the following link.[1] Turbines

Water wheels[edit | edit source]

Probably the most accessible technology for hydro power is the water wheelW. It can be built entirely from local materials. Only the generator has to be brought in. For small systems a modified motor or car alternator can be used.

- The vertical undershot water wheel is most appropriate for relative low head situations even if it is the least efficient of all water wheels. You should avoid building an undershot wheel with straight buckets and go for either a Poncelet wheel or a Zuppinger wheel which can both double the efficiency. They have an efficiency of about 30%, but enclosed like a breast shot of up to 70%.

- The breast shot is next when the head is large enough. Here the water enters at a height similar to the axle height. It is more complicated to build and needs a structure that encases the wheel to function with high efficiency. If done correctly it uses the weight of the water and its impulse. It can have an efficiency of about 85% if it's well-built.

- The over shot wheel needs the most head of the water wheels. Under optimal conditions with steel buckets it can have an efficiency of up to 80%.

- The back shot wheel can be seen as an cross between a breast shot wheel and an overshoot wheel. The water enters at the top of the wheel but the buckets are like a breast shot wheel. The direction of rotation is the same as in a breast shot wheel. The efficiency can exceed that of the breast shot.

- Horizontal water wheels apart from museum pieces are today found mainly in the Himalaya region in the form of the ghatta. That version is a primitive version of a turbine.

Building a water wheel[edit | edit source]

Regular waterwheels can be build by making the buckets at a 114° angle. The width of the wheel is best made as large as possible, so the same width as the diversion channel; the depth of the buckets is best kept shallow. Make the wheel as large as you can, making advantage of the highest waterdrop possible.

Impulse turbines[edit | edit source]

| Turbine Type | Flow | Head |

|---|---|---|

| PeltonW | Lowest | Highest >10ft |

| TurgoW | Intermediate | Intermediate >4ft |

| CrossflowW | Highest | Lowest <4ft |

Building an impulse turbine[edit | edit source]

The only machine that can be build without access to metal casting equipment or a 3D milling machine is the crossflow turbine. The only advanced tools needed are a cutting torch and welding equipment. Needed raw materials are sheet metal and metal pipe. Information how to build a crossflow turbine can be found on the CD3WD ( see Resources ) web site.

To build runners for small Pelton or Turgo turbines it is necessary to have either access to a 3D milling machine or have access to a casting shop or to build a casting shop. For the latter the largest problem is probably to get information how to build a mold for a suitable runner. For more information see Casting ( Metal )

Installing a water turbine[edit | edit source]

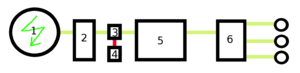

When installing a waterwheel, often a alternator or dynamo and a gear reducer or gear increaser is needed (so that the RPM of the alternator is brought to a suitble speed, converting the electrical energy efficiently).

Regardless of the type of water turbine used, the optimal power output is not obtained in practice at rotation speeds of the axle above or below what the water turbine was designed for (for example at times of high water/high flow, ...). This is due to the alternator or dynamo used, which tends to be chosen for a specific speed. If the water speed goes above or below this speed, the efficiency is much lower than what could actually be harvested at this time. This could be solved using a gearbox which may be electrically controlled (changing gear ratio's when needed). However, due to the high complexity, this is often not done and a regular gear reducer or gear increaser is used.