Face mask reviews[edit | edit source]

Link to Twitter threads or articles:

- https://twitter.com/lucasgonzalez/status/1242106679879241732?s=19

- https://twitter.com/jeremyphoward/status/1242451610242072576?s=19

- Cooperative!!! https://twitter.com/magghu/status/1241361090954571781?s=19

- crafting aunties https://twitter.com/RealSexyCyborg/status/1243095975134146560?s=19

Concepts[edit | edit source]

it could be good to set up some taxonomy of mask types and design parameters mapped to use cases.

- for use a) (eg hospitals, by doctors/nurses) masks need to be 1) 2) 3) + disposal / cleaning / sterilizing instructions because (fact x, y, z) ((not everyone will be able to fabricate these))

- for use b) eg delivery people, shopkeepers masks can be 4) 5) 6) + disposal / cleaning / sterilizing instructions because (fact u, v, w)

- for everyday street use masks can be 7) 8) 9) + disposal / cleaning / sterilizing instructions because (fact r, s, t) ((many people can make these at home))

Appropedia pages[edit | edit source]

3-D printable reusable masks[edit | edit source]

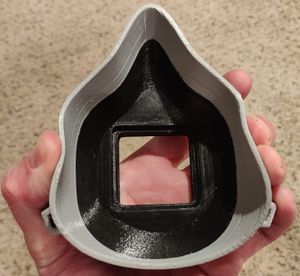

The idea behind 3D printable masks is that you use a small area of filter and replace it after use -- but then wash and disinfect the 3D printable mask components. This can help overcome the N95 mask shortage in an area as you can get up to 6 squares from a single full mask (for some types of N95s). In addition the ability to hot mold the 3D printable design to someone's face MAY offer a better more comfortable fit.

- COVID-19 MASK (Easy-to-print, no support, filter required)-Cults 3D, or from Thingiverse

- Filter is square material inserted in cavity, held by front panel.

- Very hard to ensure that air goes through the filter, not around it. Need filter material larger than open square.

- Front panel and internal grill fit is sketchy. It's easy for them to be a bad fit. Can be made easier by printing grill 1% less scale than rest of mask.

- Nose piece and strap loops have overhangs that are moderately hard to print

- The COVID-19 MASK (Easy-to-print, no support, filter required) from Cults3d printed it on a standard TAZ6 and a Creality Ender 3 in PLA 1mm outer 10% infill and made a gasket for the rim from a close-celled foam I had laying around from the old enable-hand designs. It works well just with friction fit so I don't think it even needs to be glued in. This will make the entire thing easier to disassemble and clean. The mask fits adult males well...maybe cut it down 10-15% for women and younger people.

- Billings mask "Billings Clinic" redrew and redesigned it in Fusion 360: https://longliveyoursmile.com/3d-printable-mask-for-covid-19/

- Filter is thin square fabric, sandwiched into square interface.

- Good filter-to-mask seal.

- Designed to cut multiple squares out of one surgical mask -- up to 6 per mask.

- 2 pieces rather than 3 to print and maintain.

- Larger filter opening, so slightly better for breathability.

- Overhangs are much easier to print (just a little trouble on the strap loops).

- They have provided source code (Fusion 360) for modifications.

- Copper3D mask "NanoHack"

- Easy print - but wants you to use expensive copper PLA

- Involves heating the NanoHack to 55º-60º C with a hairdryer or hot water and then bending and glueing.

Rigid Material (PLA)[edit | edit source]

- Standard printing material -- works on everything.

- Placing foam around the edge has been reported to provide a good seal, but involves access to foam.

- Not dishwasher-safe. This will melt and deform in a standard dishwasher.

- Dipping mask in boiling water for 5-10 sec allows for some facial adjustments. Here's a test using scrap PLA. Could be used to fit face of individual.

Flexible Material (Ninjaflex)[edit | edit source]

- More expensive and harder to work with. Not all printers can do it, so that's limiting.

- It has to be printed more slowly than PLA plastic, which means less throughput.

- Cleaning little goobers off the print is harder too. They have to be clipped off, as sanding doesn't work.

- Too floppy for the front filter interface.

- That said, it likely provides a more universal facial seal than something rigid.

Flexible Material (Cheetah)[edit | edit source]

- More rigid than Ninjaflex (shore 95 compared with shore 85) and easier to print.

- Many Bowden-equipped extruders can use it.

- Can print faster than Ninjaflex.

- Post-processing is easier than Ninjaflex. X-acto blade is effective at removing ooze goobers, and facial interface can be sanded for greater comfort.

- Rigid enough to support the front filter interface, so the entire print could be made from Cheetah.

- Greater rigidity means less comfort for the wearer.

Hybrid PLA / Flexible Filament[edit | edit source]

- PLA and Ninjaflex / Cheetah bond between layers is quite strong.

- Mason Stone created hybrid masks by generating two g-code print files -- one with hard plastic settings and one with flexible settings. Then edit each one, deleting the steps after preferred layer on PLA and those before preferred layer on flex. This could probably done automatically with a "tool change" in the slicer or those with dual extruders.

- Optimal placement of seam on "COVID-19 MASK" is ~30mm when printed with 100% scaling.

"Billings" Filter for COVID-19 MASK[edit | edit source]

- Mason Stone scaled the filter grid from the "Billings Clinic" and posted it Billings" Filter for COVID-19 MASK

- This now fits the "COVID-19 MASK" design and is an effective method for using a self-sourced filter as it provides a good solid fit for the filter.

Filter materials[edit | edit source]

The coronavirus is just about 0.1 microns (Particle diameters ranged from 50 to 150 nm, excluding the spikes, with mean particle diameters of 82 to 94 nm) [1]

- Cut an N95 into 6 pieces - this is the best option if available.

- Home made filters: I tried a HEPA air filter and it was too restrictive.

- What Are The Best Materials for Making DIY Masks? : SmartAir, 08-03-2020 - covers most alternative materials and their effectivenesses - and peer reviewed paper.

- Good online guide for making your own masks: Make it yourself masks has been the best place I've found to collect the data about furnace air filters in an attempt to reach N95 status.

- CDC Guide on extending use of N95s

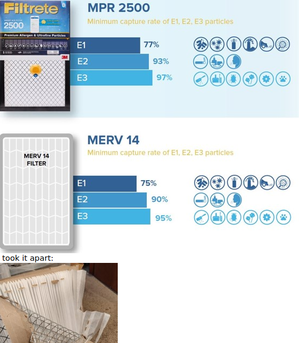

MPR2500 / MERV 14[edit | edit source]

- MPR2500 furnace filter, which is rated to block 77% of E1 (.3 to 1.0 microns) particles. ...and doubled up the material to cut a filter.

- An N95 filter is rated to block 95% of particles > .3 microns.

- With the first layer of filter, 100% - 77% = 23% of the particles can get through. With the second layer, 23% of the remaining 23% is:.23 * .23 = .0529; so with two layers of MPR2500 filter, 95% of particles > .3 microns are blocked. However, in studies the expected impacts of doubling were NOT consistent among materials: [2]

- It is far more breathable than the HEPA air filter I tried earlier, so fatigue will be lower.