The Practical Action donkey plough was developed in Sudan in the Darfur region over a period of time where a number of trials and adaptations were made to make the design suitable for local conditions. The size and weight of the plough would be varied to suite different farming conditions In 1990 Practical Action's (then ITDG) work with an Oxfam animal traction project in Sudan was rekindled after suffering from logistical difficulties. The project was based in the Northern part of the country in Darfur province around Kabkabiya.

This work led onto the Darfur Integrated Rural Livelihoods Programme that covers activities such as:

- Training farmers in agricultural techniques - terracing and wadi (valley bottom) cultivation, which extend the range of crops that can be grown and make more efficient use of scarce water resources. Around 1000 farmers are trained each year, mainly by local extension workers

- Strengthening of the capacities of local village committees to manage and develop agricultural and water projects

- Construction of dams for rainwater harvesting, and training in dam construction, as well as improvement in the techniques of construction of tumad (shallow wells) in the wadis and the construction of haffirs (channels) for water supply

- Establishing several irrigated demonstration farms Introduction of donkey carts for transporting water - for household use, and other goods, reducing the time and drudgery of collecting water, especially for women.

Most of the community share the problems of working with soils that have a hard crust. When the rains come, the water cannot penetrate the soil. The project officer, at the time, introduced an implement used by many farmers in Ethiopia, the wooden ard plough.

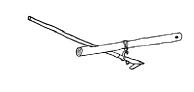

This is an assemblage of wooden pieces fitted together; it is lighter than many ploughs. The traditional design of plough for the region used a single handle that passed through a log. The log acted as the main body of the plough and only a small proportion on the plough was made of metal. The plough is made lighter than many ploughs in other part of the world due to the arid conditions and the fact that it is being pulled by one donkey only or sometimes by a camel.

The new design is based on the more traditional design but using an all-metal structure. The metal comes from scrap, which is usually obtained from old vehicles.

The Azagarfa Blacksmiths Society was part of the Practical Action project concerned with participatory technology development in the design of a donkey-drawn plough using locally available skills and appropriate materials. The blade, for example, would be made from leaf springs from old suspensions. The steel is useful as it can easily be hardened through quenching to produce a hardwearing surface.

After initial trials in the project area (Kebkabiya), this technology was scaled up and disseminated to other areas in North Darfur including Azagarfa Village.

The Azagarfa Blacksmiths Society was registered in 1998 and Practical Action (then ITDG) organised the training of its members by other blacksmiths from Kassara who were already skilled in the improved design. Members have on to manufacture and sell the ploughs to individual farmers and farmer societies in the area. The conditions in which the ploughs are manufactured are fairly basic and the tools available to the blacksmiths are limited.

The components of the plough consist of the minimal amount of material as steel is scarce. Practical Action has been involved the design of the harness in Sudan where improved harnesses have been introduced for ploughing and for water carrying. ITDG publishing has also produced a book on simple harnesses. As part of the training, new harnesses were demonstrated. The wider and softer strapping will spread the load and reduce rubbing thus preventing the animal from developing sores.

The donkey plough demonstrates the relationship between the different aspects of Practical Action's work from the adaptation of a traditional technology to the development of an intermediate technology and brings together farming, metalworking and the production of improved harnesses.

Useful Addresses[edit | edit source]

Practical Action Sudan P.O. Box 4172 Khartoum Central 1114 Sudan Tel: + 249 183 460 419 Fax: + 249 183 472002 E-mail: sudan@practicalaction.org.sd

World Association for Transport Animal Welfare and Studies - TAWS Old Stocks 62 The Avenue Worminghall Aylesbury, Bucks HP18 9LE United Kingdom Mr. Hovell Tel: 01844 339327 Robin Gripp Tel: 024 7634 3400, Email: info@taws.org Website: https://web.archive.org/web/20210125005915/http://www.taws.org/

References and further reading[edit | edit source]

- Metalworking, (Practical Action Technical Brief)

- The Harnessing of Draught Animals by Ian Barwell & Michael Ayre, ITDG Publishing, 1982

- Donkeys, Mules & Horses in Tropical Agricultural Development, University of Edinburgh 1991