This project seeks to install a low-impact irrigation system for a budding food forest and to provide clear information on the full process so that it can be replicated elsewhere. This irrigation system uses collected rainwater, a water pump powered by a photovoltaic panel, two 1000 liters collection tanks, and gravity to irrigate on-demand. The system uses drip irrigation for water distribution and is triggered by a programable automatic water timer. Planning and installation of the irrigation system was achieved within one semester at Cal Poly Humboldt. To approach the project we began by getting ourselves acclimated with what goes into a solar irrigation system and learning how to work closely with our clients. We conducted a detailed literature review on the different components of a solar-powered irrigation system. Once we gained a base-level amount of knowledge, we created a detailed plan of approach and had weekly contact with our clients at CCAT. We created a budget for the required components. A series of prototypes were made using the information we gathered from our clients to ensure our final system would be successful and met their desired criteria. Construction and testing were completed over a period of several weeks on site. As of May 2021, the completed irrigation system meets the client's criteria and is fully functional.

Background[edit | edit source]

The Campus Center for Appropriate Technology (CCAT) at Cal Poly Humboldt has established the grounds for a small food forest that is currently planted with a few saplings and covered in a layer of mulch. The vision is to provide a space for students and community members to harvest food throughout the years and to share knowledge about integrating landscapes that provide food security as an alternative to the lawns that currently dominate urban areas. This project was conceptualized in previous years by students and users of CCAT. Spring 2021 students have been assigned to create a solar powered irrigation system for the space provided for the food forest.

This project was an option of the Spring 2021 Engineering 305 class with instructor Lonny Grafman. The students undertaking this project are Luisa Close, Tineke Iris, Kyle Spears, and Samuel Killpatrick.

Problem statement[edit | edit source]

The area designated for the food forest is in need of an irrigation system to help the plants establish over the next decade. The objective is to create a low maintenance irrigation system for the food forest and provide a replicable template for other locations. Our plan is to use solar energy to pump water from a rainwater catchment tank (already installed) to the food forest area slightly down the hill from the water catchment location. The irrigation system will use rainwater collected in a nearby tank. We will use solar energy to reach a water flow adequate for the irrigation needs. The irrigation system will be used primarily during the summer months when there is seasonal drought in Humboldt county, and when not as many students are on campus to maintain the area.

Project Evaluation Criteria

The following criteria will be used to determine what are the most important aspects of the project. The ranking system is 1-5, with 5 being the highest. The rankings will help to focus efforts and budget of the solar irrigation build.

| Criteria | Constraints | Rank (1-5) |

|---|---|---|

| Budget | Keep the budget at or below $600. | 5 |

| Durability | Needs to be able to function properly for at least 2 years with easy maintenance in case irrigation fails. | 4 |

| Days of autonomy | Must be able to work without sunlight for a maximum of about 3 days | 3 |

| Ease of use | Should be very simple to use and fix. Maintenance ought to be logical and intuitive. Must not interfere with walking paths while still being moderately easy to access for repairs. | 2 |

| Educational purpose | Important aspects, such as photovoltaics, should be visible for students and visitors of the food forest to understand their function and the project's reproducibility in other locations. | 1 |

Prototyping[edit | edit source]

The prototypes were created to represent the system to end users on paper or digital versions. Our prototyping was predominantly about having a way to visualize what the system looks like for visitors and the end-users.

-

First hand-drawn sketch of the prototype

-

The digital version of the first prototype sketch

-

First draft of the poster for the setup

One of the biggest issues was trying to decide on what we could use to indicate where irrigation lines were marked. There were many options that we went through before we finally decided on using large rocks. This can be seen in the farthest right image. The other two images present more developed versions of the eventual final poster set up for the poster.

-

Rock used to show what we intended to do for markers

-

Second revised draft of the poster for the setup

Finally, we created a video with a 5 year old star actor (Max) to walk us through the current setup and indicate the changes that need to be implemented. The linked video provides a perspective what our prototype looked like as of April 2021.

Link to Prototype video on YouTube

Literature Review[edit | edit source]

See the literature review at CCAT solar irrigation for food forest/Literature review.

Construction[edit | edit source]

It is important to note that much of the irrigation was already in place (see CCAT rainwater catchment drip irrigation system/OM) upon beginning construction and multiple improvements were required to make the system functional to the specification previously listed.

- The solar-powered water pump was installed to pump water from the lower tank to the top tank. The water pump is connected to the solar panel via 12 gauge red and black wire. The red wire is used to connect to the positive lead of the solar panel. This goes through a tethered float switch that will shut off power to the pump when a low water level is reached in the lower tank. A black wire is connected to the negative lead of the solar panel.

- The pump is connected to the lower tank through an outlet and the bottom of the tank and pumps water up to the tank at the top of the hill though PVC irrigation pipe.

- The top tank has a float that operates like a toilet tank float. Once the water level rises and lifts the float it closes off the connection between the lower tank and the upper tank. This allows the pump to build up back pressure to a PSI that will shut the pump off. Therefore no water is wasted by overflowing the top tank.

- We pulled up the irrigation lines to determine if there were any breaks in the lines. One break was found and we patched it up using quick connects and a hand torch to soften the two hose pieces.

- The automatic timer was connected to the PVC pipes bringing the water down from the top tank at a location adjacent to the solar panel.

- We dug new trenches for the irrigation lines and reburied the pipes along the walking paths in the food forest to avoid any potential tripping hazards. We aimed to make the trenches at least 3-4 inches deep to fully cover the exposed pipes.

- To indicate where these irrigation pipes were buried, we lined the irrigation pathway with ~10 inch rocks spray-painted white. Many rocks included a directional set of arrows to indicate the direction in which the pipes were buried underground. These stones are a display to visitors and our clients not to dig in these locations to avoid damaging the irrigation lines.

- We worked with a fellow HSU student, Jesse Beacham Grijalva de Prieto, to design the poster for for this project and ordered the sign to be installed by the the groundskeeper at CCAT.

-

The connection to the multimeter to test the current through the pump.

-

Automatic timer for water flow to the food forest. If the valve attached to the top tank is open, this timer can be set to regulate periodic waterings.

-

Sam digging trenches for PVC irrigation tubes

-

Kyle installing the solar-powered water pump

-

Luisa spray painting rocks for buried irrigation lines

-

Rolling Thunder team on construction day

-

The solar-powered pump being installed in the housing under the solar panel

-

The solar-powered pump being installed under the panel

-

Stones indicate where irrigation pipes are buried. Digging around these locations should be avoided in order not to break the water lines.

-

Some of the rocks placed along the path indicating where irrigation lines are buried

-

CCAT food forest in April. Can you spot the stone marker?

-

Water leaking under the path where the hose had accidentally been broken

-

Irrigation strategically wrapped around the plant to spot irrigate

-

An irrigation hose that was accidentally broken when someone dug in the middle of the path where it was buried

-

Final poster design by Jesse Beacham Grijalva de Prieto

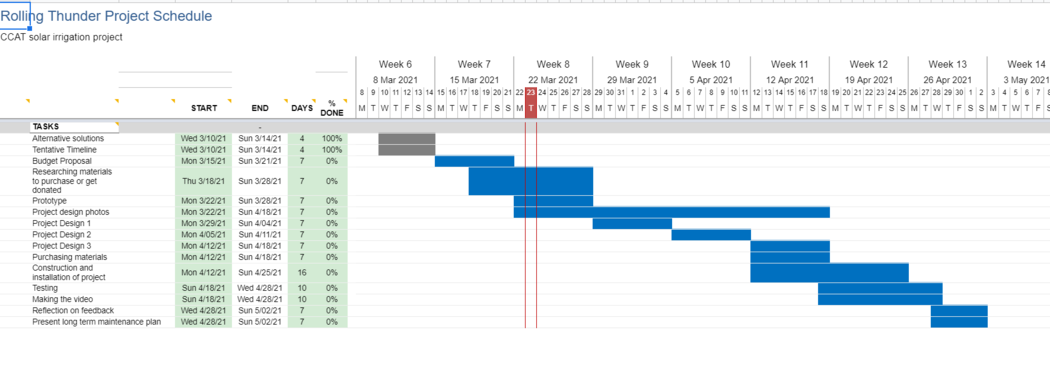

Proposed timeline[edit | edit source]

The current proposed timeline for this project can be seen on the google sheet. The Rolling Thunder team intends to have the setup completed by mid-May 2021.[1]

Costs[edit | edit source]

The following depicts the proposed budget for the supplies needed to fulfill this project at CCAT. The majority of the supplies, such as the solar panel and irrigation pipes, are already in place or available on site. The major expenses were the pump and the corrugated plastic information sign depicting the setup for visitors and future end-users. Funding for this projects is provided by CCAT and HSU.

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | Solar panel | CCAT | Free | 0.00 |

| 1 | Irrigation tubes | CCAT | Free | 0.00 |

| 1 | Pump | Shurflo 4008 | $73.00 | $73.00 |

| 2 | Quick connects | Ace Hardware | $3.00 | $6.00 |

| 1 | Automatic timer | Ace Hardware | $35.99 | $33.99 |

| 1 | Pump box supplies (lock/ wood) | Ace Hardware | $5.00 | $5.00 |

| 1 | Hardboard informational poster/ sign | Marketing Store | $120.00 | $120.00 |

| 2 | Spray paint | Ace Hardware | $4.00 | $4.00 |

| 1 | Masking tape | Ace Hardware | $7.00 | $7.00 |

| Total Cost | $248.99 | |||

Operation[edit | edit source]

- Water is collected from the roof and stored temporarily in the lower tank next to the solar panel. The lower tank has a tethered float switch inside of it that is connected to the solar panel and pump. When the water level drops to roughly 25 gallons, the float switch sinks to the off position where there is infinite resistance, hence no electrical current flowing through the component. Consequentially the pump will shut off automatically. This is so the pump is not dry pumping which leads to damaging the pump.

- The solar power harnesses energy from the sun providing power to the pump when there is direct sun on it. During the spring and summer months, the optimal time for the sun to fully hit the panel is between 2 and 4 pm. This is also the best time to verify that the pump is working as long as there is water in the lower tank.

- The pump pushes water in the lower tank up a hill into another holding tank. The top tank utilizes a float similar to that in a toilet tank. When the water gets to the maximum (roughly 275 gallons) capacity, the float rises to the top closing off the inlet valve. This allows the pump to use back pressure to build up to a PSI that shuts off the pump. This prevents overfill and water waste, and burning out the pump.

- The water then flows to the food forest by way of gravity if the outlet valve is opened allowing the water to flow downhill through to an automatic timer. The automatic timer can be set to regulate the water. 10-minute increments set for once or twice a week should provide enough water to keep the plants alive during months with little to no rain.

-

Tethered Float Switch for solar pump inside the lower tank. The pump will turn on if there is enough water in the lower tank and enough solar power to start the pump up.

-

Tethered Float Switch diagram

-

The float used in the top tank. When the water rises the black float rises closing the connection from the pump and lower tank to the top tank.

Maintenance

The amount of maintenance required aims to be as low as possible.

Clearing out the gutters which capture the rainwater periodically is important as these can become filled by leaves and pine needles over time. The system runs automatically due to the automatic timer, the setting on this can be modified according to the instructions on the automatic timer's user manual. The battery will need to be replaced annually in order to keep the automatic timer functioning (the timers screen shows battery health). The water tank should be cleaned periodically and the lid should be tightly secured to ensure there are no mosquitos breeding in the tank.

The rainwater catchment system needs to be cleaned periodically as well as the tanks. The system should be reviewed every semester to make sure all is functioning. The tanks obviously need water in them in order for the system to function. The pump will only function if the sun is shining directly on the solar panel. Pump maintenance can be found under the solar pump's user manual.

-

Tineke cleaning out the gutter

-

Lower water tank near the food forest in need of maintenance. The lid should be tightly secured so mosquitos don't breed.

Schedule

Beginning and end of drought months

- Open the valve off the top tank to allow the water to flow down to the food forest.

- Set the automatic water timer to desired irrigation frequency. See: automatic timer's user manual

- During rainy months when irrigation is unnecessary, the valve at the top tank should be is closed as the system will be dormant

Monthly

- Verify the water levels in the tanks to ensure availability of water storage

- Make informed decisions on water timer settings based on capacity and watering needs

- Clean out the gutters on the roof that collects the rain water

Yearly

- Change the battery in the automatic timer

- Check the tanks for debris buildup and tight-fitting

- Check to make sure there are no irrigation breaks and that irrigation in the food forest drips are near the plants that need it.

- Every 2 years

- Reorganize the rocks that indicate where the irrigation lines are buried, clear out vegetation growth or buildup

- Clear out any overgrown plants around the pump or sign to ensure clear visibility and ability to service tanks, pumps, and irrigation lines

Instructions

Testing and operation instructions can be found in the video below

https://www.youtube.com/watch?v=IOtrKGMzZ-s

Conclusion[edit | edit source]

Testing results

-

Kyle testing the voltage between the solar panel and the tethered float

-

The current being provided to pump from the solar panel in full sun

-

Connecting the multimeter to the pump to test current by inserting it into a break in the wires leading from the pump to the panel

-

CCAT food forest irrigation poster with CCAT crew delivered and approved on May 9th 2021

Power to pump from PV panel

The solar panel and pump were tested for flow rate and power provided to the pump from the panel. When the solar panel was in full sun the pump was drawing an average of 4.42A at 17V which is 75.14 Watts(W=A*V). At the power, the water was flowing from the bottom tank to the top tank at a rate of 31.5L per minute. To test the amps the negative line was broken from the pump to the solar panel. Testing the voltage was done simultaneously with a second multi-meter. The negative lead from the multimeter was touched to the same break in line where the multimeter testing the amps was and the positive lead was touched to the positive connection from the solar panel to the pump.

Flow Rate Filling Top tank during pump activity

The flow rate was measured using a stopwatch. The stopwatch was running when the pump was in full power pumping water from the bottom tank to the top. The clock watch started at 200 liters and was timed until the tank reached 300 liters. This took roughly 9 minutes and 30 seconds, which is where the 31.5L per minute flow rate was measured.

Flow Rate irrigating the food forest

Measured using a stopwatch and measuring the amount of water that flowed through the drip irrigation in a 30-minute cycle. The outflow rate was ~ 5 liters per minute. During the 30 minute cycle, 150 liters of water flowed through the drip emitters into the food forest.

Discussion[edit | edit source]

After testing we have concluded that the system will work sufficiently to the requirements we wanted the system to meet. The testing results show that the panel provides more than sufficient power to move the water from the lower tank to the top tank. It should take approximately 95 minutes to transfer 1000 liters from the bottom tank to the top tank based on the flow rate with full power from the panel to the pump.

There are currently no leaks in the system. Our only major concern is that the water line breaks due to visitor's carelessness. Finding the leak may be a challenge for future users.

We recommend that the irrigation is set to water for 10 minutes every 3 days. This would release ~50 liters of water from the top tank per disbursement. That would allow for approximately 20 days total of releasing water. If spaced out every 3 days, this would allow one full tank to operate the irrigation system for ~6 weeks. This is subject to change depending on the clients' needs.

Lessons learned[edit | edit source]

Throughout this project, there were many lessons learned around issues we didn't anticipate being issues at the start of the project. These lessons will help us be better prepared for future projects of this nature.

One lesson learned was learning how to meet the needs of clients and how to professionally interact with them. Trying to balance what the needs of the end-users and clients are with what can feasibly be accomplished in one semester challenging. An example of this was figuring out how we can mark where irrigation lines underground. We had to go through many different possibilities that were inspired by nature, not fully permanent, but still easily visible. The option that we were most excited about did not meet the client's needs, thus requiring a complete rework. Making sure we communicated with the clients about proposals and prototypes was a vital part of the project. We also had to learn how to communicate the system with end-users, especially since CCAT has new staff every year. We needed to figure out a way to provide information and a variety of tools to the end-users in a way that was useful and does not lead to an overload of information.

We also needed to deal with the issue of sunlight given Humboldt county's fluctuating weather patterns. If we planned a day to test the solar panel, and it was forecasted to be sunny, there was always the possibility that it would be cloudy. Having to be flexible and prepare some cushion time in case it became cloudy was necessary for this project to have successful testing.

Learning to start the project with a clear understanding of the initial layout of the site and its layout before beginning the project was a hard lesson. Had we gone to the site before starting our brainstorming process and prototyping, we could have saved lots of energy and time. We would have known that much of the system was already in place, and the main issue we need to accomplish was fixing the system and figuring out ways to improve it.

Testing the voltage, current (Amps), and power (Watts) generated from a solar panel using a multimeter was a useful skill learned. Being able to measure the power (Watts= Amp x Volts) draw of the pump from a solar panel was also a useful lesson. There were also parts of the project that seemed like they would be simple or would not require much research, however, in practice these portions lead to some of the most thorough work. An example of this was during the research and purchasing of the pump. Initially, we had not thought it would take much work or research to find a pump that would fit our needs. However, there were many factors to consider (head, flow rate, etc.), but research into this was crucial to get the longest life out of the system. We also had to take into account getting a size that works the best for our system to ensure the pump will have the longest life.

Next steps[edit | edit source]

Beyond simply sticking to the maintenance schedule consistently to keep the system in working order, some possible next steps that could be taken in the future to improve the current design:

- Expansion of the solar food forest irrigation systems to include more plant beds and water a larger area as a result.

- Installation of some sort of system built to capture potential runoff, with an additional pump and irrigation lines that could be used to pump this water back up to the water tank.

- We noticed that a lot of the parts of the system already in place required repair. In particular, the rain gutter utilized for rainwater catchment, much of which is currently sitting out of line with the irrigation tubes leading to a lot of the rainwater it catches flowing out of the system and missing the pipe. As a next step, we could work to improve pieces of the irrigation system in need of repair to make it run smoother and more efficiently.

- To limit damage from the sun's rays all remaining irrigation tubes above ground could be buried and marked in the future.

- An additional tank could be placed at the top of the hill to capture more water during the rainy season.

Troubleshooting[edit | edit source]

More information on the initial setup for this project prepared by previous ENGR 305 students can be found at:

CCAT rainwater catchment drip irrigation system/OM

- Backtrack from the food forest to the top tank and feel for water flow in the PVC pipes

- Emitter might be clogged due to small solids in the drip line. Check the emitter and clean it with a needle to remove dirt or other precipitates.

| Problem | Suggestion |

|---|---|

| Pump not running | -Check to make sure the solar panel is providing power

|

| No water flow to the automatic timer | -Make sure the valve on the right-hand side from the top tank to the food forest is open

|

| Water draining from the top tank while the system is shut off | |

| Emitter not delivering water

(where water drips out of irrigation lines) |

Team[edit | edit source]