In the research of semiconductor and nanosciences, the dimensions of the substrate fall into a great variety. Substrates with irregular dimensions are quite often used. However the processing tools including accessories are mainly designed for commercially available substrates. This problem is more prominent for wet chemical etching processes, due to the safety issue and accurate time control of sample handling.

Customized wet etching tools may be provided by a limited amount of suppliers. However, the ordering period is quite often long and the price is high. Moreover, it is time-consuming to justify the compatibility for different lab environment of wet etching tools from unfamiliar suppliers.

This project is aimed to close the gap between the consumer need and commercial availability of chemical wet etching accessories by 3D printing, taking advantage of open source software, such as OpenSCAD, FreeCAD, Blender, and Lulzbot Edition Cura. Customized wet etching tools can be designed and printed rapidly at low cost. The compatibility of the 3D printing item will be studied later on, while it is out of the scope of this project.

This project was performed as a final project of the L3999 course Fall 2017.

Designer: Zhengjun Liu' Aalto University, Department of Electronics and Nanoengineering

Design[edit | edit source]

The designed item for this project is a slide-on jig handle for a commercially available wet etching jig for 3-inch wafers. The item was chosen due to the urgent need for our research, while the ordering time of such a product would be 8 weeks.

Precedure[edit | edit source]

- Sketch the jig profile with freeCAD, and the file is availave on NIH repository.

- Choose the filament according to the requirement of chemical resistance. In our case, we used polypropylen (PP) filament.

- Set the printing parameters.

Cost estimation[edit | edit source]

Filament cost: €3 (€43/0.8kg)

A commercially available equivalent costs more than €100.

Printing parameter optimization[edit | edit source]

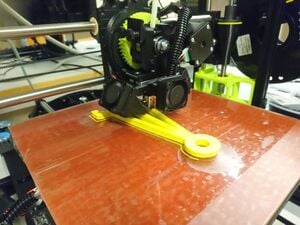

Due to that it is difficult to remove the PP prints from the printer platform, the platform was taped with packing tape before printing. Nevertheless, the tape inflated and deformed during printing due to the platform heating, which consequently led to the deformation of the prints. Turning off the platform heating may eliminate the tape deformation. Keeping the heating and leaving off the tape may also possible when releasing assisting structure is added to the design.

On the other hand, the handle printed with PLA filament is flawless in appearance. Due to the low chemical resistance of PLA, the PLA handle is not usable for acid etching process.