Project Title

Project developed by aakruzel(talk) 4:46, 5 December 2019 (UTC)

Template:Statusboxtop Template:Status-design Template:Status-prototype You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Abstract

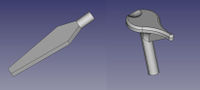

- A bike seat is a simple, but necessary part of a bike that holds most of the weight of the biker. In many developing countries, biking is the most common mode of transport. Additionally, a mud flap is important for keeping the rider clean, especially during rainy seasons.

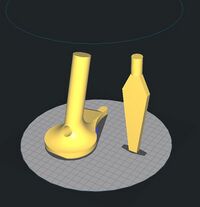

- Picture of completed print setup in Cura

Bill of Materials

- Available plastic that can be 3D printed, and glue/adhesive

- Link to all applicable files needed to create part. [1]

Tools needed for fabrication of the OSAT

- MOST Delta RepRap or similar RepRap 3-D printer

- Depending on type of bike, an allen wrench or screw driver may be needed to attach seat.

Skills and Knowledge Necessary to Make the OSAT

- General 3D printing knowledge is needed to make parts.

Technical Specifications and Assembly Instructions

- Recommended Print Settings: Temp=210, Material=PLA, Layer Height=0.3mm, Infill=25%

- Print Time Estimate: 4 hours 20 minutes

- Assembly Time Estimate: 15 minutes

Common Problems and Solutions

- A common problem is the tolerance for the assembly is too tight. To solve this, use a thicker wall thickness and use sandpaper to create a snug snap fit.

Cost savings

- If your solution is not a low cost one then it is not really appropriate.

- Estimated Cost(57g): ~=$1.14

- Commercial equivalent, Seat $17.98 [2]]

- Commercial equivalent, Mud Flap $19.95 [3]

- Cash Savings: $36.79, Percent Savings: 97.14%