No edit summary |

|||

| Line 1: | Line 1: | ||

=Overview= | =Overview= | ||

{{777}} | {{777}} | ||

Project developed by [[User:Rmputzig]] | Project developed by [[User:Rmputzig]] | ||

{{Statusboxtop}} | {{Statusboxtop}} | ||

| Line 21: | Line 19: | ||

== Tools needed for fabrication of the OSAT== | == Tools needed for fabrication of the OSAT== | ||

# [[Delta_Build_Overview:MOST| MOST Delta RepRap]] or similar RepRap 3-D printer | # [[Delta_Build_Overview:MOST| MOST Delta RepRap]] or similar RepRap 3-D printer | ||

# Exacto knife or similar product for removing support structures | |||

== Technical Specifications and Assembly Instructions== | == Technical Specifications and Assembly Instructions== | ||

# Print out the part. Be prepared to | # Print out the part. Be sure to generate supports for the print. Be prepared to spend time removing the the support structures. | ||

# Print time: ~40 mins. | # Print time: ~40 mins. | ||

== Cost savings== | == Cost savings== | ||

# 3D printed part: | # 3D printed part: ~50 cents (depending on size) | ||

# Commercial part: $2-$6 | # Commercial part: $2-$6 | ||

# Minimum cost savings of 75% | # Minimum cost savings of 75% | ||

Revision as of 15:28, 4 December 2014

Overview

Project developed by User:Rmputzig

Template:Statusboxtop Template:Status-design Template:Status-prototype You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Abstract

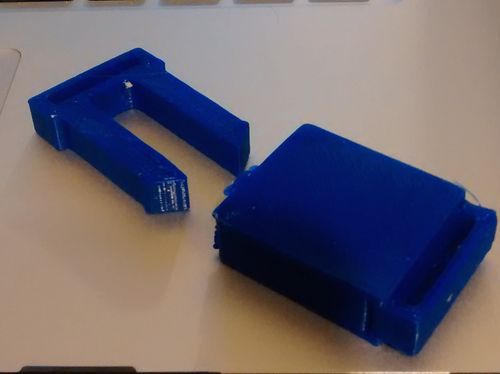

This type of clip is found on a variety of items, most commonly backpacks, and work well. However, I have found that if you break one, it is difficult to find a replacement, and are overpriced (typically $2-6 for 1 set!). Since it is made of plastic and only plastic, I wanted to make a parametric OpenSCAD design. There are many designs for there out already, however few provided source code and even fewer were scalable.

Bill of Materials

- Filament of your preferred color

- Design files as found here

Tools needed for fabrication of the OSAT

- MOST Delta RepRap or similar RepRap 3-D printer

- Exacto knife or similar product for removing support structures

Technical Specifications and Assembly Instructions

- Print out the part. Be sure to generate supports for the print. Be prepared to spend time removing the the support structures.

- Print time: ~40 mins.

Cost savings

- 3D printed part: ~50 cents (depending on size)

- Commercial part: $2-$6

- Minimum cost savings of 75%