These are the steps that our team The Trailer Park Boys used to construct our bicycle trailer. The components below include a wheel chair, a conduit frame, a road sign tub, a cover, the tongue, and hitch. Instructions are listed below for each component.

Preparing the Wheelchair[edit | edit source]

The wheelchair is an essential item in our design.

- Disassemble wheelchair into individual parts.

- Determine which parts of the wheelchair frame will remain.

- Remove excess material from wheel chair frame.

- Grind and file cuts

- The wheelchair frame will be the starting point from which the rest of the frame will be constructed.

-

Disassembled wheelchair

-

Determining where the cuts are to be made.

-

Making Cuts

-

Shave off rough ends

The Frame[edit | edit source]

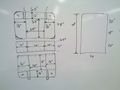

The primary material of the frame was galvanized 3/4" conduit. Small sections of standard water pipe where used as well.

- After acquiring conduit, sketch a rough layout for the frame

- Using a conduit bender, bend the conduit appropriately based out your layout. (Note practicing with the conduit bend beforehand is good idea)

- Cut the water pipe into eight four inch sections, these will be used to attach the conduit to the wheelchair frame.

- Braze or weld the water pipe to the wheelchair.

- Cut eight six inch section of conduit and cut parallel half circles in the end, these will separate the two horizontal loops of the frame

- Tack weld the frame together and check for general fit before permanently welding the frame together.

-

Rough sketch.

-

Using a conduit bender to bend conduit.

-

Four pieces of cut water pipe.

-

Braze the larger bends of conduit to the wheelchair

-

Tack weld the smaller cuts to the conduit frame for temporary stability

Street Sign Tub[edit | edit source]

The tub was constructed entirely out of two aluminum street signs.

- Measure dimensions of your frame to sketch dimensions of your tub.

- Use a jig saw to cut the signs to your dimensions.

- Two sections of angle iron clamped to a table can be used as a solid base to make the appropriate bends in the sign.

- Use a large round object if rounded bends need to be made.

- Using extra sections of your sign for backing strips, pop rivet the tub together. (It helps to place the tub in the frame before riveting)

-

Tub dimensions

-

Cut the signs using a jig saw

-

Use a mallet and a piece of wood to hammer the road sign that is set against a sharp, straight edge.

-

The back end of the trailer is rounded. We used a rounded piece of aluminum to hand bend the tub to the correct position.

-

One side bent to the correct position.

-

Tabs cut out aluminum to be used for riveting

-

Pop riveting the tub together

-

The completed road sign

Cover Installation[edit | edit source]

We used Kokotat material supplied by SCRAP Humboldt for it's great defense from the elements

- Take measurements of the tub dimensions for a rough cut. Add additional length to drop down the sides for snaps and for vertical slack (in case payloads are taller than sidewalls).

- Once the cover is rough cut, lay atop the tub to fold, cut and trim as needed for a more finished fitting.

- Acquire snaps and separate female and male parts.

- Drill holes through the tub and pop rivet the male snaps in place.

- Use a proper punch to secure female snaps to Kokotat.

-

Sewing the cover.

-

Male ends fastened to tub.

-

Female ends fastened to the cover.

Tongue Instillation[edit | edit source]

We used conduit to construct the trailers tongue as well for maximum stability.

- The first bend you want to make is a 90 degree bend that lies parallel with the front of the trailer

- Next the pipe will need to be bent so that it has a lift from the ground, rotate and make another bend so that the desired section of the pipe is ten inches off of the ground

- The tongue needs to be attached to the frame. Our solutions was to mold some of the excess road sign into a shell that fit around both the frame and the tongue and bolt road sign shell and tongue together.

-

Here is how our tongue came out. It has two different types of bends so it can be hitched to the bike.

-

The tongue once it is fastened with bolts.

Hitch Construction[edit | edit source]

The primary components of the hitch are an aluminum slug, heim joint, angle iron, and hitch pin.

- The aluminum slug was fitting to the inside of the open end of the tongue.

- The aluminum slug was then drilled and tapped appropriately for the already acquired heim joint.

- Next the slug was fastened to the conduit via machine screws.

- A nut with a lock washer was threaded onto the heim joint prior to threading heim joint into the slug. This allows the heim joint to be fixed in a horizontally position

- The receiving end of the hitch is simply a small section of 1/4" angle iron that has be shaped and drilled to fit the rear axle diameter and the hitch pin.

-

This aluminum slug that is used to connect the heim joint and tongue together.

-

The heim joint before it is threaded into the aluminum slug

-

The heim joint is threaded into the aluminum slug which is fastened to the end of the tongue

-

The complete and assembled hitch assembly.