Team Innovations Explained has been set out on a quest to make two simple machines for the Redwood Children's Museum in the Fall semester of 2022. Stephanie Carter is the executive director of the Redwood Discovery Museum. She aims to bring more exhibits to the museum. Stephanie wants the exhibits to engage children ages 8-12 years old and their parents in a safe, exciting, and educational way.

Background[edit | edit source]

Team Innovation Explained from Cal Poly Humboldt located in Arcata, CA was given a task in the fall semester of 2022 by the Redwood Children's Museum located in Eureka, CA to make two simple machines for new exhibits at the children's museum. The museum wanted newer exhibits because they needed to fill empty space and replace some old exhibits. Our target audience is children ages from 8-12, this age group needed more engaging exhibits at the museum.

Problem statement[edit | edit source]

The objective of this project is for team Innovations Explained to create exhibits that clearly and simply demonstrate the function and concepts of screws and pulleys to children from ages of eight and upward.

Criteria[edit | edit source]

Stephanie Carter, the director of the Redwood Discovery Museum, gave our group specific parameters that must be met. Listed below are the specifications, considerations, criteria, usage and production volume required to be met by our final designs.

| Criteria | Description | Weight |

|---|---|---|

| Safety | Must comply with title 22 section 101239 fixtures, furniture, equipment and supplies. | 10 |

| Attractivness | More attractive than 50% of the other exhibits in the museum. | 10 |

| Cost | No greater than $500 in supplies. | 10 |

| Reliability | Must live for two to three years on museum floor. | 10 |

| Uniqueness | Will incorporate 50% or more aspects of Humboldt industry. | 8 |

| Excitment | More than three ways for guests to interact. | 9 |

| How much children learn | No less than four concepts will be taught. | 8 |

Prototyping[edit | edit source]

The students built the first prototypes at the University Cal Poly Humboldt makers space. The main goal here was to create a small-scale exhibit using similar mechanical components to those used in the final design. Later prototypes became more detailed and provided a clear vision for our final projects. Materials consisted of plywood, recycled wood, pulley's, rope, cardboard, and lastly 3D and 2D autoCAD to model the exhibit at a bigger scale.

-

Functional pulley prototype (Nick Weiser)

-

Pulley system AutoCAD drawing (Nick Weiser)

-

Screw AutoCAD prototype (Kyle Amann)

Final product[edit | edit source]

The photo below is the final outcome of the Archimedes Screw, which is composed of an all thread axle which is rotated by a wooden handle at the bottom of the screw. We included a return system which catches the wooden balls and spits them out into an ABS pipe where they will be ready to be used again at the users discretion.

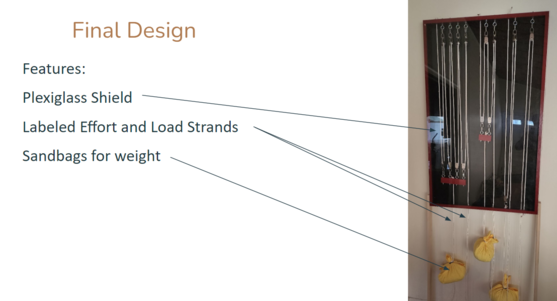

The photo below is the final design of the Pulley System, which is composed of a plexiglass shield which keeps fingers and other things safe from pinching and smashing. It is also composed with sandbags for weight and feeling the difference between all mechanical advantages.

The photo below is the final design of the Pulley System, which is composed of pulleys ranging from one to four pulleys which provide different mechanical advantages such as a 1:1, 2:1, and a 4:1 system.

Construction[edit | edit source]

Pulley Cabinet Construction[edit | edit source]

The construction of the Final Pulley Cabinet was done in two phases. Roughing and Finishing.

Roughing consisted of cutting the 1/2 inch plywood that creates the backdrop of the exhibit down from a full sheet of plywood to 32 x 48 inches, as well as rip cutting poplar boards to 1 1/2 inches by 3/4 inches. The top and bottom pieces of poplar are 32 inches long, while the sides nestle in and are 46 1/2 inches long.

Construction of the frame was simple, clamp and pilot drill the poplar pieces as they stand on the side that is 3/4 inches, flush with the edges of the 1/2 inch ply. Predrill 5 Holes along the top and bottom, avoiding rope holes with a bit that is slightly smaller than a drywall screw. Do 7 holes for the sides. Screw frame sides in using a 1 1/2 inch drywall screw.

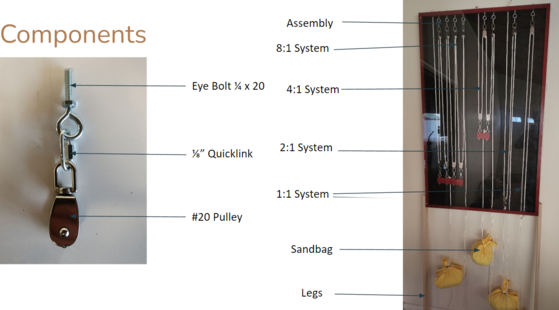

Finishing was much easier. We started by painting the sides of the frame red, and the back of the frame black. Holes were drilled to allow for proper spacing of eye bolts, and then the eye bolt, quick link, and pulley are all installed, as seen in the second figure below. Two smaller pieces of poplar are needed to mount the second half of the 8:1 and 4:1 systems, these pieces are 8.5 and 4.5 inches long. The pulleys here are mounted in the same fashion as previously used.

For the last few things, thread rope through the pulleys, and thread them through the holes at the top and bottom of the frame to make exhibit useable. Tie stopper knots to keep the rope from slipping through the frame and into the system.

Mount a sheet of plexiglass to the front of the exhibit by gently drilling 1/8 inch holes 3/8 inches from the edge of the plexiglass sheet that measures the same dimensions as the outside of the frame. Use a sheet metal screw to fasten the plexiglass to the frame.

-

This is an image of the main pulley backdrop before paint.

-

This is an image of the pulley cabinet complete minus the rope and sandbags.

Archimedes Screw Construction[edit | edit source]

To begin construction of the screw, the reclaimed wood was cut with a miter saw. The wood that attaches to the pillow blocks was cut at 25 degrees to provide the proper angle for the screw to be secured. The wood was attached to the base using corner braces and wood screws. The 3D printed pillow blocks were screwed into the wood that was cut at the 25-degree angle. STL file for 3d printed pillow blocks https://www.myminifactory.com/object/3d-print-kp08-bearing-holder-104340

ABS sheeting was cut using shears in a donut shape measuring 5 ½ inches for the outside diameter and 2 1/8 inches for the inside diameter. The donut shaped ABS sheeting was then cut laterally so the sheeting could be stretched. The sheeting was then placed on the 1 ½ ABS pipe and then stretched using a heat gun to provide a 2-inch gap. The sheeting was epoxied every 2 inches for 3 feet to create a series on incline planes that spiral up the ABS pipe.

The completed screw was attached to the clear acrylic tube using a #10 all thread and locknuts to ensure the internal screw would turn with the clear tube. The ABS pipe was capped at both ends and a 5/16 hole drilled in the center. The all tread was inserted through the pillow blocks with ball bearings and the screw all the way to the base. 5/16 lock nuts were placed throughout to attach the screw to the base. A wooden handle was then constructed and attached to the bottom of the all thread to allow the screw to be turned.

A 2 1/8 hole was drilled into the tube to allow a wooden ball to be inserted into the screw. At the top end of the screw a catchment and return system was constructed using left over ABS pipe and fittings to catch the balls and return them to the bottom end of the screw. It was secured using wood screws attached to the pillow block supports and the plywood base.

-

This is an image of Kyle Amann gluing together the screw mechanism.

-

This is an image of the Screw mechanism starting to come together.

-

This is an image of the completed screw mechanism.

Bill of materials[edit | edit source]

This table lists the cost of materials used in the construction of the Vortex Exhibit. The team had a total of $500 to spend. The Redwoods Discovery Museum provided the team $200 and each team member was asked to contribute up to $75 in the case where the $200 was not enough to cover construction costs. Not all materials used were bought.

| Cost of Prototypes | Item | Amount | Cost Per Unit | Total |

|---|---|---|---|---|

| Plywood | 1 | $10 | $10 | |

| Pulleys | 10 | $2 | $22 | |

| Popular wood | 1 | $24 | $24 | |

| Acrylic Sheet | 1 | $16 | $16 | |

| Rope | 1 | No Cost | No Cost | |

| Total | $72 | |||

| Cost of Final Pulley System | Item | Amount | Cost Per Unit | Total |

|---|---|---|---|---|

| Hardware | 15 | $5.53 | $83 | |

| Pulleys | 15 | $2.50 | $37.5 | |

| Poplar Wood | 1 | $30 | $35 | |

| Plexiglass | 1 | $80 | $80 | |

| Rope | 1 | $40 | $40 | |

| Total | $275.5 | |||

| Cost of Final Archimedes Screw | Item | Amount | Cost Per Unit | Total |

|---|---|---|---|---|

| Clear Tube | 1 | $50 | $50 | |

| ABS Sheets | 1 | $38 | $38 | |

| Epoxy | 2 | $15 | $30 | |

| 5/16 Bolt Nuts | 15 | $0.60 | $9 | |

| Other Materials | 1 | No Cost | No Cost | |

| Total | $127 | |||

Maintenance[edit | edit source]

The Pulley system and the Archimedes screw require minimal maintenance. These machines are all hand powered so there will be no utilities needed to power these exhibits. Wooden ball replacements and replacing the pillow blocks are the only things that may possibly need to be replaced if they are damaged or lost. These machines should be checked weekly for loose bolts and frayed rope.

| Replacement Costs | Item | Cost |

|---|---|---|

| Wooden balls | $10 | |

| Rope | Provided | |

| 3D Print Pillow Block | ~$0.15 |

Maintenance schedule[edit | edit source]

- Daily

- Check for frayed rope.

- Check to see if any wooden balls are missing.

- Check to see if both mechanisms are working properly.

- Weekly

- Check for frayed rope.

- Check for loose nuts and bolts.

- Monthly

- Check for loose nuts and bolts.

- Check for frayed rope.

- Yearly

- Check for mold are dry rot on the wood.

- Check for frayed rope.

Conclusion Of Final Design[edit | edit source]

File:Screwvideo (Kyle Amann).mov

After some 108 hours of design work and building, both the Archimedes Screw and pulley system were successfully created and function as they should. The Redwood Discovery museum can now add two new interactive exhibits to their floor that are safe and educational. Both exhibits were designed with safety, durability and cost effectiveness in mind to ensure they are appropriate for the Redwood Discovery Museum and its young audience. We hope these exhibits can provide a fun learning experience for museum visitors for years to come.

Innovations Explained Fall 2022[edit | edit source]

References[edit | edit source]