This is a biodigester built using commonly available IBC containers

-

Gas container

-

Lid detail

-

Los Angeles installation

-

Gas collector detail

Why IBC?[edit | edit source]

This is a biodigester and gas capture system that can be easily built by amateurs using commonly available components

- Low cost

- Standard size for comparing experimental data

- Open Source design

History[edit | edit source]

Thomas Culhane designed and innovated this HDPE Plastic IDB Tote 3-tank water-displacement pressurized biogas system in Cairo, Egypt and built the first one working with Solar CITIES associates Hanna Fathy and Mike Rimoin and students from the SEKEM Environmental Science Center in October 2009 after many experiments on his own porch in Essen Germany. After building many ARTI India style telescoping biogas digestors in Cairo Egypt throughout the previous year Culhane realized several improvements were necessary for spreading the technology out of the East and Middle East to colder climates. In 2013 Thomas decided to make the design explicitly 'Open Source'

Project goals[edit | edit source]

- Encourage others to build IBC biodigesters

- Collect and share data about real world performance

- Innovate

- Iterate new designs

Design[edit | edit source]

The initial design has been documented here Until all details are documented here it's worth using this link as a reference.

The design details will be copied here to; Improve awareness of the design & ensure the design remains available through Appropedia

Parts list & Costs[edit | edit source]

| Part | Cost in US | Cost in UK |

|---|---|---|

| 3 x IBC Tote HDPE 1000 liter (275 gallon) water tanks | $100 | £25 each |

| 4 meters of 1/2 inch clear plastic tubing | ? | £12 |

| 5 X 1/2" Poly Tank Flanges | $6.33 each ? | UK term: Bulkhead fitting £4.96 each |

| 1" Poly Tank Flange Assembly | ? | UK term: Bulkhead fitting £9.95 |

| 2" Poly Tank Flange Assembly | ? | UK term: Bulkhead fitting £2.99 |

| To be completed check link above | row 2, cell 2 | row 2, cell 3 |

| To be completed check link above | row 2, cell 2 | row 2, cell 3 |

| To be completed check link above | row 2, cell 2 | row 2, cell 3 |

| To be completed check link above | row 2, cell 2 | row 2, cell 3 |

Additional Components[edit | edit source]

Bicycle powered food grinder[edit | edit source]

HS2 Scrubber[edit | edit source]

Hydrogen Sulphide, or 'Rotten Egg' gas, will combine with the moisture in the biogas to form sulphurous acids and these can corrode almost anything. The way to get rid of it is to give it something to corrode that you don't want; like some steel wool, for instance, in a wide-necked bottle or flagon. It must be of clear glass with the gas inlet pipe running down to the bottom of the container and an outlet pipe coming away near the top. Of course, the whole thing needs to be gas-tight. As you use the gas, the steel wool will corrode from the bottom upwards taking up the hydrogen sulphide by conversion to black iron sulphide which can later be reused after being oxidised to rust (ferric oxide) by exposure to air, although the process is slower than the initial scrubbing one was. When the black corrosion reaches 75% of the height of the container, or so, it's time to change the steel wool or ferric oxide for fresh, sacrificial stuff. Diagram here

C02 Scrubber[edit | edit source]

There is some interest in using algae to scrub C02 from biogas. This is relatively untested, although being investigated at a commercial scale

Biogas Burners & Lights[edit | edit source]

A review has been carried out by by SNV (Netherlands Development Organisation) in 2009. More here

Internal Combustion engine adaptation[edit | edit source]

There are a number of ways to modify small 4stroke (not 2stroke) engines to run on biogas. More here

Ideas for further innovation[edit | edit source]

- Using strawbale construction to insulate the digesters

- Using low- tech solar heating (black radiator & glass approach)

- Using high tech solar heating (evacuated solar tubes)

- Using small catalytic heaters to keep digester warm

- Using algae systems to convert C02 output to Oxygen

- Eliminating the need for pump; using gas pressure alone.

- Using media in the digester to provide homes for Methanogens; plastic? charcoal?

- Using waste heat from showers, baths to keep digester warm

- Using Geodesic domes as greenhouse/ shelter

- Developing 3d printed plumbing parts for the digestor

Data Collection & Sharing[edit | edit source]

In order to meaningfully compare different experimental designs it would be great if experimenters could share

- Information on design tweaks they have made

- Temperature data from inside and outside their digester

- Information on volumes of gas produced

- Information on the type and volume of feedstock used

- PH information from the digester

It might be interesting to develop some Arduino based internet connected data loggers for those that can afford them

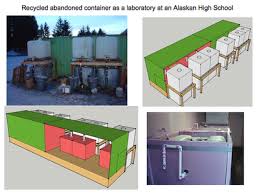

Alaskan digesters[edit | edit source]

Location

Photo

Build details

Inside, the 40 foot steel Conex shipping container has been insulated on all surfaces with two inch insulation board, dashing pink was the selected color. A wall has been installed in the middle of the container with a door in order to manage two separate environments with temperatures of 25 and 15 degrees Celsius respectively. Each of the two compartments contains three digesters, one with psychrophiles only, one with mesophiles only, and one with both psychrophiles and mesophiles in a mix

Data

1,000 litre digester using psychrophiles harvested from "mud from a frozen lake in Alaska has produced 200–300 litres of methane per day, about 20 to 30% of the output from digesters in warmer climates.

Some detailed data reports are available here;

TH Culhane's German installation[edit | edit source]

Location

Build details

Built within a greenhouse.

Data

Temperature data from outside and inside the tank has been collected. Will be added here when available.

Sao Paulo Brazil[edit | edit source]

Example build report (Please add yours!)[edit | edit source]

Location

Photo

Build details

Data

References[edit | edit source]

Discussion[edit | edit source]

There is an Facebook group to discuss the development of this digester.