Appendix

Appendix A: Assembly BOM

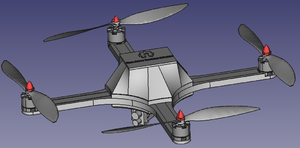

| Part Number | Part Name | Quantity | Weight (1 Part) | Part |

| 1 | Top Plate | 1 | 69g | Center Plate Top.FCstd |

| 2 | Bottom Plate | 1 | 71g | Bottom Plate With Camera Mount.FCstd |

| 3 | Front Left Arm | 1 | 42g | Front Left Arm.FCstd |

| 4 | Front Right Arm | 1 | 42g | Front Right Arm.FCstd |

| 5 | Arm | 2 | 43g | Arm.FCstd |

| 6 | Center Cover | 1 | 49g | Cover V3.FCstd |

| 7 | Arm Cover | 4 | 5g | Sliding Cover.FCstd |

| 8 | Feet | 4 | 3g | Feet.FCstd |

Appendix B: Assembly Procedure

This assembly procedure describes the required steps to completely assemble the quadcopter.

- The table below lists all the required hardware and tools necessary to completely assemble the frame and components of the quadcopter.

| Component | Description | Quantity |

| Fastener | M4 x 0.7 x 25 | 12 |

| Fastener | M2 x 0.4 x 15 | 12 |

| Fastener | M3 x 0.5 x 10 | 4 |

| Heat Set Insert | M4 x 0.7 | 12 |

| Tooling | Description | Quantity |

| Allen Key | M4 | 1 |

| Allen Key | M2 | 1 |

| Allen Key | M3 | 1 |

| Soldering Iron | Typical Soldering Iron | 1 |

| Needle Nose Pliers | Small | 1 |

- Install the heat set inserts into the top plate of the quadcopter by placing the heat set inserts above the countersunk holes. Note, 4 of the holes are not countersunk, the remaining heat set inserts will be used in step 8 to secure the cover to the rest of the frame. Place the soldering iron inside the heat set insert and apply a small amount of pressure downwards making sure that the heat set insert gets installed straight.

- Run the wires through the frame of the quadcopter prior to assembling each component together.

- Insert the M4 screws into the bottom plate and slide the arms over these M4 screws before installing the top plate on top and secure all parts together using the heat set inserts installed in step 2.

- Insert 4 M2 screws through each foot as it is held to the bottom of the arms. Once the M2 screws are inserted through the feet and arms, secure both parts to the motor by installing the M2 screws into the appropriate holes in the bottom of the motors.

- Place the Arduino on top of the standoffs on the top plate. Check clearances to ensure that the one standoff with the notch cut in it corresponds to the corner of the Arduino that requires extra clearance and secure the Arduino to the standoffs using the M3 screws.

- Complete the wiring according to the wiring diagram pictured in Figure 13.

- Obtain the center cover of the quadcopter. Insert one of the M4 screws through the holes in the cover from the bottom. Thread the heat set insert onto the M4 screw on the inside of the cover. Use a pair of needle nose pliers to hold the head of the M4 screw while a soldering iron is placed on the M4 screw. Note, the screw, heat set insert, and soldering iron will be extremely hot during this step, proceed with caution.

- Gently pull the M4 screw down while heating with the soldering iron until the heat set insert is installed into the cover, ensuring that it is straight.

10. Verify the wiring is correct and upload the MultiWii code to the Arduino using the USB cable.

11. Secure the cover to the quadcopter using the remaining 4 holes and M4 screws in the frame.

12. Install the propellers on the motors.

13. Now the quadcopter is ready to fly.

Appendix C: Flight Procedure

Before flight, there are a few steps that need to be taken for the quadcopter to safely fly. Failure to follow these steps could result in damage to the quadcopter, property, or nearby participants.

- Ensure that the propellers are secured properly to the motors.

- Place the quadcopter on a level surface.

- Plug in the battery to the wiring harness.

- Turn on the controller.

- Verify the ESCs arm. You will hear a distinctive beep pattern after plugging in the battery.

- Arm the quadcopter by moving the left throttle stick to the bottom left for 3 seconds, then to the bottom right for 3 seconds until the motors begin to spin at their idle speed.

- The quadcopter is now ready to fly.

Appendix D: Technical Data Sheets

The technical data sheets for all purchased components can be seen below, where each of these data sheets were either sourced directly from the manufacturer's website or from the third part distributing the data sheets.

| Part | Technical Data Sheet |

| Emax MT2213-935KV Motors | EMX-MT-1534- EMAX Multicopter motor MT2213 (With Prop1045 Combo)935KV | Emax (emaxmodel.com) |

| Arduino Uno R3 | Arduino: Page Not found | Arduino Documentation | Arduino Documentation

UNO-TH_Rev3e.sch (arduino.cc) |

| Turnigy MultiStar BLHeli-S Rev16 V3 30A ESC | Print (hobbyking.com)

turnigy_brushless_esc_manual.pdf (hobbyking.com) |

| RunCam Hybrid Micro FPV 4K Camera | RC Hybrid Manual_EN_191205.ai (runcam.com) |

| Flysky FS-i6X i10 Transmitter | FS-i6+User+manual+20160819.pdf (squarespace.com) |

| Flysky FS-iA6B Reciever | FLYSKYIA6B 2.4 GHz 6 CHANNELS RECEIVER User Manual 未å'½å -1 FLYSKY RC MODEL TECHNOLOGY (fccid.io) |

| GY-85 9DOF IMU | GY-85 9DOF IMU Sensor Module [GY-85] - US $10.50 : HAOYU Electronics : Make Engineers Job Easier (hotmcu.com) |

Appendix E: PETG Material Properties9

| Material Properties of Thermoplastic PETG - Exceptionally Durable | ||||||

| Property | Metric | units | English | units | ||

| General | ||||||

| Density | 1.26e3 - 1.28e3 | kg/m^3 | 0.0455 - 0.0462 | lb/in^3 | ||

| Mechanical | ||||||

| Yield Strength | 4.79e7 - 5.29e7 | Pa | 6.95 - 7.67 | ksi | ||

| Tensile Strength | 6e7 - 6.6e7 | Pa | 8.7 - 9.57 | ksi | ||

| Elongation | 1.02 - 1.18 | % strain | 102 - 118 | % strain | ||

| Hardness (Vickers) | 1.41e8 - 1.56e8 | Pa | 14.4 - 15.9 | HV | ||

| Impact Strength (un-notched) | 1.9e5 - 2e5 | J/m^2 | 90.4 - 95.2 | ft.lbf/in^2 | ||

| Fracture Toughness | 2.11e6 - 2.54e6 | Pa/m^0.5 | 1.92 - 2.31 | ksi/in^0.5 | ||

| Young's Modulus | 2.01e9 - 2.11e9 | Pa | 0.292 - 0.306 | 10^6 psi | ||

| Thermal | ||||||

| Max Service Temperature | 51 - 64 | °C | 124 - 147 | °F | ||

| Melting Temperature | 81 - 91 | °C | 178 - 196 | °F | ||

| Insulator or Conductor | Insulator | Insulator | ||||

| Specific Heat Capability | 1.47e3 - 1.53e3 | J/kg °C | 0.352 - 0.366 | BTU/lb. °F | ||

| Thermal Expansion Coefficient | 1.2e-4 - 1.23e-4 | strain/°C | 66.8 - 68.1 | µstrain/°F | ||

| Eco | ||||||

| CO2 Footprint | 3.22 - 3.56 | kg/kg | 3.22 - 3.56 | lb/lb | ||

| Recyclable | Yes | Yes | ||||

| Dielectric Manufacturing, Richfield, Wisconsin USA dielectricmfg.com | ||||||