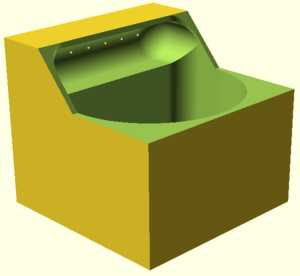

This is a design which can be 3D printed or machined out of metal (for greater longevity) using a CNC Machining Center. The design is made using OpenSCAD and is mostly parametric, allowing for adjustments in volume, wall thicknesses, and pouring hole sizes to suit the needs of the task. This design allows for mixing multi-part resins in the rounded body of the container as well as pouring wide, even lines of resin out of multiple holes at the top.

Bill of Materials[edit | edit source]

- Materials Needed:

- Approximately $3.00 of filament (can be adjusted for thinner walls, smaller size, etc. to reduce cost)

- Alternate: 4" x 4" x 6" (100mm x 100mm x 150mm) aluminum block for machining

- STLs and Open-Source (OpenSCAD) Source Files Download

Tools needed[edit | edit source]

- Jellybox or similar RepRap 3-D printer

- Alternate: Computerized CNC mill capable of 2 pass (top-down and back-front) aluminum milling

Common Problems and Solutions[edit | edit source]

- If attempting to pour resin and nothing / not enough is coming out, increase diameter of pouring holes