Surge Tank[edit | edit source]

A surge tank is a storage reservoir that is on the downstream end of a water source that mitigates sudden bursts in water flow.[1] Surge tanks are very helpful in systems where the grey water is being treated. This initial tank stores water and allows for an even flow of water to the next stage in the process. This stops flooding to certain parts of the system that takes longer, like filters and pumps.[2]

Siphon[edit | edit source]

A siphon is a tube or pipe that is used to transfer water from one reservoir to another, on a lower level, without the use of a pump. Siphons contain steady flow using suction or immersion. An example of this would be a dosing siphon, where it uses suction, gained from breaking a vacuum, to obtain a constant flow.[3]

Pumping[edit | edit source]

While many systems will be gravity fed, there is still the case where one would need to pump the water. This may be the case in a situation with the filtration system being uphill from the initial output. This can be done with a general water pump, and is the easiest method for such scenarios. Unfortunately, this does not mean it is the most efficient.

Construction[edit | edit source]

Designing a new greywater system for CCAT is crucial because students and community members read and hear about CCAT's greywater treatment system and they often come by with questions. This new and improved greywater system will provide an approachable and informative demonstration of just one the innumerable ways to install greywater treatment systems. Our design is unique because it relies on a hand-cranked drum pump to convey greywater from CCAT's subterranean settling tank to the demonstration tub on the surface. Pumping greywater presents a risk and challenge because the wide variety of waste present can clog and degrade pumps. We felt we had to pump the greywater because the previous underground pipe is dysfunctional and inaccessible. If the water is allowed to sit for too long in the settling it will become black water which poises health risks to all CCAT visitors. The pumped greywater system will allow CCAT to convey greywater into the treatment tub at its convenience instead of the greywater remaining stagnant and turning into black water. Gravity fed greywater systems are simpler and more reliable but in this instance we were forced to incorporate a pump into our system.

Changes to old System[edit | edit source]

After careful consideration of the design to the new system, the old greywater marsh had been deemed ineffective and was thrown out as an idea for the new system. We decided, along with our client CCAT, that the best bet for this old system was to get rid of it. The pit was decided to be made into a Huegelkultur type site because just filling the old grey water marsh was not cost effective, and there were better resources that could be used. Huegelkultur is a German word meaning "hill culture", and is the practice of composting large woody material in a raised bed. CCAT fortunatley enough had an abundance of this large woody materials that could be used in turning the old greywater marsh into a Huegelkultur site. This turned out to be a benefit to us because it was cost effective for our budget, and was a benefit to CCAT because it eliminated a safety hazard.

The filling of the pit is as follows. (Bottom to Top)

- -clay bed

- ->large wooden stumps

- ->larger sticks to cut branches

- ->smaller sticks

- ->mulch

- ->top soil

- Filling the Old Greywater Marsh

-

The tedious task of taking out the old constructed greywater marsh.

-

Inflow pipe for overflow.

-

Close up to inflow pipe for overflow.

-

Protective barricade for inflow pipe

-

Filled pit.

Sizing[edit | edit source]

Typical methodology for sizing constructed wetlands is based on finding the total surface area of the treatment area. Because our team was working with a fixed area (the bathtub) we decided to size for flow rate or treatment capacity of our system; that is, how many gallons of water per day can the system treat while still meeting desired BOD5 threshold for the effluent.

To back up a step and define some key terminology, BOD5 is a quantification of how much dissolved oxygen is used by microorganisms during the oxidation of organic material, contained in some effluent[4] In other words, it is the amount of biodegradable organic material in a substrate. The '5' implies that the test to measure this parameter was conducted over a five-day period. Bod is always measured in parts per million or mg/L. Influent describes the initial, untreated water flowing into the system while the effluent describes the treated water that flows out of the system.

The goal of system treatment is BOD5 reduction, based on influent and effluent comparison. Reported greywater BOD5 concentration ranges from a specific site are 45-330 mg/L,[5] while other estimations report an average of 65 mg/L..[6] Typical treated effluent (or water exiting the system) from natural systems ranges from 2-7 mg/L.[7]

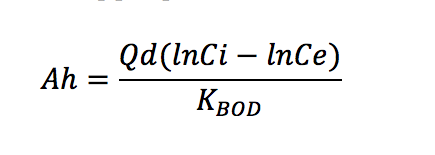

The chosen methodology for sizing our system was initially found in literature[8] and a is also the suggested approach on appropedia (see Subsurface flow constructed wetland for greywater).

Where:

- Ah= Surface Area of bed (m2)

- Qd = Average daily flow rate (m3/day)

- Ci = Influent BOD5 (mg/L)

- Ce = Effluent BOD5 (mg/L)

- KBOD = Rate Constant

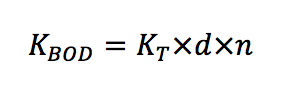

KBOD describes the rate at which BOD is removed (which is essentially the goal of treatment) and is temperature specific.

Where:

- KBOD = Rate constant at 20°C

- KT=K20 (1.06)T-20 (day-1)

- T = Average lowest monthly temperature (°C)

- d = Depth of water column (m)

- n = porosity of substrate medium (% expressed as a decimal)

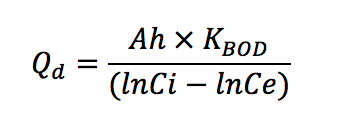

Because our team sized for flow, we rearranged the equation:

Where:

- Ah= 0.8 m2 based on fixed dimensions of bathtub

- K20= A value of 1.1 day-1 was assigned based on research for wetland systems

- T = 10°C based on reported monthly temperatures and the evapotranspiration zone Arcata falls in

- d = 0.41 m based on the fixed depth of the bathtub

- n = 0.38 based on the chosen filtration medium of pea gravel

- Ci = 75 mg/L based on BOD loading estimation

- Ce = 5 mg/L based on desired results

With these values, our sized flow rate was equal to 7.47 gal per day or 52.3 gal per week, accounting for 23.2% of CCAT's total greywater discharge.

Pump[edit | edit source]

Our team decided early on that we would not be able to rely on existing conveyance infrastructure, and since the settling take is surrounded on three sides by impermeable surfaces we determined that most viable direction for our greywater to go was up. We initially planned to build a hand pump using PVC pipe, wooden gates, and recycled valves from soda bottles. After weeks of prototyping, it became clear that our team did not possess the skills to make a reliable hand pump on our own. A few months into the planning of the projected we decided to purchase a pump. This posed a new question, do we look for a hand pump or do we look for something mechanical? Greywater is home to microorganism, food scraps, fats, and all sorts of other pieces of effluent that make it difficult to pump cheaply and simply. Of course there are large submersible trash pumps that can handle the job, however these pumps were cost prohibitive and CCAT was worried about them being forgotten and left to deteriorate. Because of these possible issues with mechanical pumps, we decided to install a rotary drum pump like the ones used to remove oil from barrels. We decided on a cast iron rotary drum pump because it was simple, cheap, and seems reliable. One concern is that this pump was designed to pump oil so there is concern that using it to repeatedly pump water could cause rust that could make speed up the deterioration process. There is a possibility that the fats and oils from the kitchen could help keep the rotary drum lubricated, but only time will tell. Our pump has the capacity to provide 10 GPM to our marsh demonstration.

Treatment Area (Bathtub)[edit | edit source]

As mentioned above, the component of constructed wetlands that is typically sized for is treatment area. Treatment area describes the ground surface area that is generally the only visible part of a subsurface constructed wetland. Depth is not sized for because it is based on selected plant species ability to develop rhizomal networks, and so values based on plant rooting depths are used instead. However, because our system favors accessibility over capacity, we decided to work with a fixed, above ground treatment area: the bathtub.

The decision to utilize a bathtub was in alignment with a number of our criteria, although it is rather unconventional within the scope of constructed wetland implementation. The tub was recovered from a local scrap yard, fitting the requirement for recycled materials. The subterranean greywater effluent pipe from the house necessitated a pumping component if the treatment system was to be above ground; the bathtub represented the potential for not only an above ground, but also interactive treatment area. Finally the aesthetical value of the bathtub was consistent with the criteria as well.

The bathtub is curved around the sides, and tapers downward so average dimensions were taken based on top and bottom measurements. Our team found a total surface area of 0.8 m 2 (8.6 ft 2). The bathtub depth was found to be approximately 0.45 m (1.6 ft). A depth of 0.4 m was used with the assumption that the roots of the selected plant species would eventually colonize the entirety of the subsurface volume. Two baffles sets were installed, constructed of recycled wood and pond liner. Each set is 0.34 m (1.1 ft) from their respective ends of the bathtub. One set constitutes a first 0.27 m baffle that is secured at the base of the tub and a second baffle that is suspended by approximately 92 mm (3.63 in), (or the width of a standard brick) and a height of 0.36 m (1.2ft) (excluding the height of the brick). Each baffle within a set is spaced 0.13 m (0.43 ft) away from each other, and the two sets have a distance 0.34 m (1.1 ft) between them (from the last baffle of the first set and first baffle of the second set.)

The influent pipe was placed 0.25 m (0.82 ft) from the bottom of the tub, and the effluent pipe was secured 0.2 m (0.67 ft) from the bottom of the tub on the exiting side, resulting in about 5 cm (2 in) of head. This difference in pipe elevation was necessary for the employment of gravity as the driving mechanism for water flow through the wetland system; without head the water would sit stagnant. Additionally the tub was place on an existing natural gradient, which our team was unable to report. The filtration medium of pea gravel (with a porosity of approximately 38%) was filled to a height ranging from 5-7 cm (2-2.7in) below the lip of the tub.

Marsh Plants[edit | edit source]

Constructing a system of plants for our greywater marsh will help us reach the goal of lowering excess nutrients, nitrogen and phosphorous, that can allow for growth of unwanted bacteria. As well as lowering the Biological Oxygen Demand (BOD) of the water. The reason we focus on the BOD is because it is an indirect measure of the organic material in the water. BOD represents the amount of oxygen needed by anaerobic biological organisms to break down organic material. We can then use this information to decide how many plants we need for our system.

Once we knew how many plants will be needed for a safe BOD, we chose the plants best for our climate and very small ecosystem. Here in Arcata, we have a large scale constructed wetland that processes all of the water from the city.[9] The plants originally planted at the Arcata marsh for filtration purposes are Hardstem bulrush, Sago pondweed and Hydrocotyl.[10] Each of these plants has rhizomes, an underground root system or modified stem that increases anaerobic degradation of organic matter and nitrification.[11] As well as microorganisms living in their roots that reduce the BOD and breakdown settled algae. Leading to a reduction of excess nutrients, and healthier water.

Our team recycled bullrush from the decommissioned greywater marsh at CCAT, as these plants were doing their job and were not the problem with the system, as well as added. In order to find which emergent plants are best for your greywater system, check out the Appropedia page Emergent plants for constructed wetlands.

Timeline[edit | edit source]

| Item | Description | Date | Date met? | |

|---|---|---|---|---|

| Start prototyping | We will begin the process of designing our pump system and obtain bathtubs. | Week 2/06/17 | YES! | |

| Prototyping | We will begin soil testing and anything left over from the previous week | Week 2/13/17 | YES | |

| Survey aesthetics and meet with the Arcata Marsh | We will begin watching how many people interact with the system to get a feel if people are attracted to it based off of how it looks. As well as meet with the Arcata Marsh to ask about their systems. Also, still continuing the prototyping process. | Week 2/20/17 | YES | |

| Plant implementation/Prototyping/BOD testing | We will be finalizing various plants, as well as the bath tub configuration. | Week 2/27/17-3/06/17 | YES | |

| Full client agreement/Start building project | We will finalize the client agreement as well as begin the construction of the finished project. | Week 3/20/17 | YES | |

| Prototyping/Building | We will work on building the project and begin designing/prototyping different pumps. | Week 3/27/17 | YES | |

| Construction and Design Updates | We will work on constructing the project by prepping the area for installation. As well as work on design updates and creating the design for the garden (end use). | Week 4/3/17 | YES | |

| Acquiring Materials | We will begin purchasing needed materials such as piping, plants and the bathtub. | Week 4/10/17 | YES | |

| Deconstruction of Old Site | The team will tackle the old marsh site. Doing so by digging up the greywater marsh and filling the hole with other materials so that the space can be used in the future. | Week 4/17/17 | YES | |

| Finishing Up Construction | Building and installation the wildflower planter box. Placement tub in new location and leveling out of the tub. Installed baffles. | Week 4/24/17 | YES | |

| Finish Construction/Surveying | We will finish building the system by installing the gravel and marsh plants. As well as start working on educational signs and begin surveying people's usage of the finished system. | Week 5/1/17 | YES |

Costs[edit | edit source]

This project is entirely endorsed and funded by CCAT for the two-part purpose of greywater management and a demonstrative platform for educational opportunity. In alignment with our client criteria, we plan to construct our proposed system using 80% reused material, much of which will be supplied by CCAT itself. Other sources of reused material we plan to utilize are Arcata Scrap Yard, SCRAP Humboldt and the Arcata Marsh.

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | Bathtub | Arcata Scrap Yard | 20.00 | 20.00 |

| 2 | PVC Pipe | Arcata Scrap Yard | 5.00 | 10.00 |

| 1 | Wood Chips | Wes Green Landscaping | 35.00 | 35.00 |

| 1 | Yard Soil (Pete moss/bark) | Wes Green Landscaping | 35.00 | 35.00 |

| 1 | Yard of #3 rock | Wes Green Landscaping | 35.00 | 35.00 |

| 4 | Scraps of wood for baffles | CCAT | Reuse | - |

| 1 | Yard of sand | CCAT | Reuse | - |

| 1 | Pond Liner | CCAT | Reuse | - |

| 1 | 10 GPM Action Pump | Amazon | 64.11 | 64.11 |

| 1 | Post-Pump Filter Screen | CCAT | Reuse | - |

| N/A | Marsh Plants | Arcata Marsh | Donation | - |

| 3 | Large Wooden Stumps | CCAT | Reuse | - |

| N/A | Cut Tree Branches | CCAT | Reuse | - |

| N/A | Mulch and Top Soil | CCAT | Reuse | - |

| 1 | PVC Primer and Glue | Ace Hardware | 6.99 | 6.99 |

| 1 | Thread Seal Tape | Ace Hardware | 1.29 | 1.29 |

| N/A | Couple | Ace Hardware | 1.29 | 1.29 |

| N/A | 2 inch Galvanized Floor Flange | Ace Hardware | 15.99 | 15.99 |

| N/A | Screws | Ace Hardware | 0.76 | 0.76 |

| N/A | Whiskey Barrel | Craigslist | 70.00 | 70.00 |

| 3 | metal clamps | Ace Hardware | 5.00 | 5.00 |

| N/A | 1.5 inch rubber couple | Ace Hardware | 4.00 | 4.00 |

| N/A | 2 inch threaded nipple | Ace Hardware | 2.00 | 2.00 |

| N/A | 4 ft of PVC | Ace Hardware | 5.00 | 5.00 |

| N/A | 1.5 inch PVC couple | Ace Hardware | 3.00 | 3.00 |

| Total Cost | $309.43 | |||

Operation[edit | edit source]

This is how to operate and maintain the 2017 greywater system at CCAT. It is very important that the system is maintained and cleaned per this schedule. If not, the system will fail to treat the greywater and it will become a health hazard to have this system on [[CCAT] grounds.

Maintenance[edit | edit source]

The greywater marsh has been designed to be as easy to maintain as possible. Most necessary tasks are to be done once every month and only take a few minutes.

Schedule[edit | edit source]

- Weekly

- Pump greywater into the system once a week.

- Monthly

- Clean oil trap

- Yearly

- Clean settling tank

Instructions[edit | edit source]

These are the step-by-step instructions on how to maintain this greywater marsh.

References[edit | edit source]

- ↑ Merriam-Webster. Accessed January 31, 2017. https://www.merriam-webster.com/dictionary/surge%20tank.

- ↑ Ludwig, Art. Create an oasis with greywater: choosing, building, and using greywater systems, includes branched drains. Santa Barbara, CA: Oasis Design, 2006.

- ↑ "How Siphons WorkOperation of Single Automatic Siphons." How Dosing Siphons Work | Fluid Dynamic Siphons, Inc. Accessed January 31, 2017. http://www.siphons.com/how-siphons-work.html.

- ↑ http://web.archive.org/web/20170707052703/http://drinc.ucdavis.edu:80/dairyp/dairyp9_new.htm.

- ↑ http://www.sswm.info/sites/default/files/reference_attachments/WAFLER%202008%20Small%20scale%20Constructed%20Wetlands.pdf

- ↑ Casanova, L.M., V.Little, R.J.Frye, and C.P.Gerba 2001. A survey of the microbial quality of recycled household graywater. Journal of the American Water Resources Association (JAWRA) 37(5)

- ↑ Crites, Ronald, and Techobanoglous, George, 1998, "Small and Decentralized Wastewater Management Systems", Water Resources and Environmental Engineering.

- ↑ N-HABITAT, Constructed Wetlands Manual. "Water for Asian Cities Programme Nepal." (2008).

- ↑ http://web.archive.org/web/20180930082351/http://www2.humboldt.edu:80/arcatamarsh/overview.html

- ↑ http://www.ecotippingpoints.org/our-stories/indepth/usa-california-arcata-constructed-wetland-wastewater.html

- ↑ http://wst.iwaponline.com/content/35/5/117