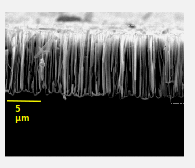

A systematic investigation is performed to determine the effects of the concentration of silver on metal assisted chemical etching (MaCE) for nanostructure formation mechanisms on silicon as well as their resultant optical properties. Silver nitrate concentrations of 8mM, 4mM, 3mM and 2mM with hydrogen fluoride were used for the preparation of p-type silicon nanostructures. Experimentally, it is observed that when the catalysis molarity concentration is decreased in the etching processes, it resulted in nanostructures ranging from 140 to 60 nm, respectively over the concentrations investigated. A detailed analysis of the optical properties and structure provided insight into the physics of their formation. In addition, the results show the silicon nanostructures formed black silicon where in the visible region of the spectrum the reflectance dropped by an order of magnitude. The results indicate MaCE is a promising approach to the manufacturing of antireflection coatings on black silicon-based solar photovoltaic cells. MaCE is a simple and scalable approach to enhance the optical absorption of silicon and improve the overall efficiency of the solar cell without adding significantly to the complexity, capital expenditure or cost of production.

Highlights[edit | edit source]

- Two-step metal assisted chemical etching of polished p-type Si wafers.

- Silver nitrate molar concentration by varying the solute volume.

- Formation of nanowires and random nanostructures depending on silver nanoparticle (Ag NPs) formation.

- Ag NPs size and surface coverage varies with silver nitrate molar concentration.

- Reflectance dropped below 5% in the UV region and 5-15% in the visible region for nanowires.

Keywords[edit | edit source]

Metal assisted chemical etching; Silver catalyst; Silicon nanostructures; anti-reflection; Photovoltaic

See also[edit | edit source]

- Influence of metal assisted chemical etching time period on mesoporous structure in as-cut upgraded metallurgical grade silicon for solar cell application

- MACE nano-texture process applicable for both single- and multi-crystalline diamond-wire sawn Si solar cells

- Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing

- Advances in plasmonic light trapping in thin-film solar photovoltaic devices

- Plasmonic Perfect Meta-Absobers for a-Si PV Devices

- Multi-resonant silver nano-disk patterned thin film hydrogenated amorphous silicon solar cells for Staebler-Wronski effect compensation

- A new method of preparing highly conductive ultra-thin indium tin oxide for plasmonic-enhanced thin film solar photovoltaic devices

- Ambiance-dependent Agglomeration and Surface-enhanced Raman Spectroscopy Response of Self-assembled Silver Nano-particles for Plasmonic Photovoltaic Devices