Hannah Stoll (talk | contribs) |

Hannah Stoll (talk | contribs) |

||

| Line 40: | Line 40: | ||

# Include print time estimate | # Include print time estimate | ||

Assembly time estimate: 15 minutes | Assembly time estimate: 15 minutes | ||

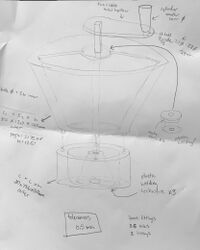

Drawing of Assembly: | |||

[[Image:Peanut_mill_layout.jpg|200px]] | |||

Revision as of 08:51, 6 December 2018

Peanut Mill

Project developed by Hannah Stoll

Template:Statusboxtop Template:Status-design Template:Status-prototype You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Abstract

- This hand powered machine is a food processing tool that will grind peanuts down so they can be made into peanut butter. There aren't many 3D printable milling devices out there. This entire mill is 3D printed and was designed with all open source technology. Food processing mills and machines are expensive to buy, so this printable one allows people in need to have tools that work.

Bill of Materials

- Fully 3D printable (I used 1.75mm PLA filament)

- Upload and link to all source files from open source CAD

- Upload and link to all STLs

Tools needed for fabrication of the OSAT

- MOST Delta RepRap or similar RepRap 3-D printer

Skills and Knowledge Necessary to Make the OSAT

Technical Specifications and Assembly Instructions

Directions for Assembly:

- Fit center rod into internal grinder

- Place it in the outer grinder

- Put bearing top on the center rod

- Slide funnel on and snap pegs to outside of outer grinder

- Line up bearing top and bottom on funnel with center rod running through them

- Plastic join the bearing top and bottom

- Plastic join the internal grinder with the bracket

- Snap on connector arm to center rod

- Snap on handle to connector arm

- Include print time estimate

Assembly time estimate: 15 minutes

Drawing of Assembly:

Common Problems and Solutions

- Plastic welding: The point of doing this in two places was to eliminate the need for screws and washers to make this completely printable. It is difficult, but placing the nozzle in the holes given and extruding +40 gives a good weld.

The pegs on the funnel just snap around the outer grinder. I had an issue with the original part, but this was the quick fix.

Cost savings

- If your solution is not a low cost one then it is not really appropriate.

- Estimate your costs

- Find a commercial equivalent

- Calculate $ savings and % savings

Benefited Internet Communities

- Name and add links to at least 5 using single brackets around [url name]

References

- The sources of information (e.g. engineering handbooks, journal articles, government documents, webpages, books, magazine articles etc.). References should use the <ref> </ref> and <references/> tags and can be in any format but should include all the information necessary for someone else to find the same information you did. For example: [1]

- ↑ web page: Department of Energy (DOE) Landscaping and Energy Efficiency, DOE/GO-10095 (1995) Available: http://www.eren.doe.gov/erec/factsheets/landscape.html

Based on the developmental needs addressed (e.g. food, heat, electricity, clean water, health care, etc.) be sure to label your device in the proper categories e.g. use [[Category:Water]]. Be sure to categorize your device so that it will be easy to find – for example “Low voltage connection basics” is categorized in [[Category:How tos]] [[Category:Electricity]] [[Category:Electric lighting]].