No edit summary |

No edit summary |

||

| Line 21: | Line 21: | ||

*[[file:masonary_toolbase.stl|Masonry Tool Base]] | *[[file:masonary_toolbase.stl|Masonry Tool Base]] | ||

Purchased | Purchased materials | ||

* | *JB weld | ||

== Tools needed for fabrication of the OSAT== | == Tools needed for fabrication of the OSAT== | ||

# [[Athena Build Overview| MOST Delta RepRap]] | # [[Athena Build Overview| MOST Delta RepRap]] | ||

| Line 32: | Line 31: | ||

== Technical Specifications and Assembly Instructions== | == Technical Specifications and Assembly Instructions== | ||

- The masonry tool base slicer settings were | |||

*Layer Height: 0.25 mm | |||

*Top/Bottom layer thickness: 0.75 mm | |||

*Shell Thickness: 1.4 | |||

*Fill Density: 100% | |||

*Printer Speed: 30 mm/s | |||

*Travel Speed: 50 mm/s | |||

- The masonry handle slicer settings | |||

*Layer Height: 0.25 mm | |||

*Top/Bottom layer thickness: 0.75 mm | |||

*Shell Thickness: 1.4 | |||

*Fill Density: 60% | |||

*Printer Speed: 60 mm/s | |||

*Travel Speed: 50 mm/s | |||

- Print times: 2 hr 46 min for the tool base and 59 min for the handle- total time: 3 hr 45 min | |||

-Assembly | |||

*JB weld was placed on the short end of the handle and the handle was placed in the middle of the tool base (2 1/16 in from the long side and 4 in from the short side of the tool base) | |||

| Line 42: | Line 55: | ||

== Cost savings== | == Cost savings== | ||

* | *70 g of PLA filament were used which was a total cost of $1.12 at $16 for 1 kg of PLA filament | ||

*The JB weld cost $3.00 for 2 oz of JB weld but only about .5 oz was used in assembly which cost about $0.33 | |||

*Adding up both costs the total cost is $1.45 | |||

*Trowels can range in price from $3.00 to $50 | |||

*The cost savings would be $1.55 to 48.55 | |||

*The cost savings in percent would be 51% to 97.1% | |||

==References== | ==References== | ||

Revision as of 01:27, 8 December 2015

Title of the device or system

Project developed by Ethan Marshall

Template:Statusboxtop Template:Status-design Template:Status-prototype You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Abstract

- The concrete trowel can be used as a cheaper method for smoothing concrete walls and could be used for smoothing out plaster on walls in developing countries. This trowel would help fulfill the needs of affordable tools for concrete and interior work on houses and buildings in developing countries

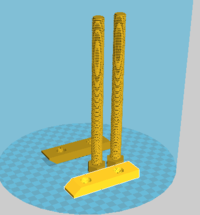

- Picture of completed print using

Bill of Materials

CAD files of parts FreeCAD files found here

STL

Purchased materials

- JB weld

Tools needed for fabrication of the OSAT

Skills and Knowledge Necessary to Make the OSAT

- N/A

Technical Specifications and Assembly Instructions

- The masonry tool base slicer settings were

- Layer Height: 0.25 mm

- Top/Bottom layer thickness: 0.75 mm

- Shell Thickness: 1.4

- Fill Density: 100%

- Printer Speed: 30 mm/s

- Travel Speed: 50 mm/s

- The masonry handle slicer settings

- Layer Height: 0.25 mm

- Top/Bottom layer thickness: 0.75 mm

- Shell Thickness: 1.4

- Fill Density: 60%

- Printer Speed: 60 mm/s

- Travel Speed: 50 mm/s

- Print times: 2 hr 46 min for the tool base and 59 min for the handle- total time: 3 hr 45 min -Assembly

- JB weld was placed on the short end of the handle and the handle was placed in the middle of the tool base (2 1/16 in from the long side and 4 in from the short side of the tool base)

Common Problems and Solutions

- Include common mistakes/problems to avoid in building your OSAT and how to overcome them

Cost savings

- 70 g of PLA filament were used which was a total cost of $1.12 at $16 for 1 kg of PLA filament

- The JB weld cost $3.00 for 2 oz of JB weld but only about .5 oz was used in assembly which cost about $0.33

- Adding up both costs the total cost is $1.45

- Trowels can range in price from $3.00 to $50

- The cost savings would be $1.55 to 48.55

- The cost savings in percent would be 51% to 97.1%

References

- ↑ Construction in Africa, KPMG (2014) Available: https://www.kpmg.com/Africa/.../Construction%20in%20Africa.pdf