Chapter 2: Structure of Wood[edit | edit source]

The fibrous nature of wood strongly influences how it is used. Specifically, wood is composed mostly of hollow, elongate, spindle-shaped cells that are arranged parallel to each other along the trunk of a tree. When lumber is cut from the tree, the characteristics of these fibrous cells and their arrangement affects such properties as strength and shrinkage, as well as grain and pattern of wood.

A brief description of some elements of anatomical structure are given in this chapter.

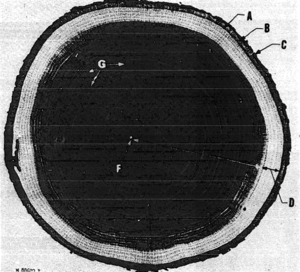

Figure 1 shows the cross section of a white oak tree trunk. The labels represent: A, Cambium layer Imicroscopic) is inside inner bark and forms wood and bark cells. B, Inner bark is moist. soft, and contains living tissue. Carries prepared food from leaves to all growing parts of tree. C, Outer bark containing corky layers is composed of dry dead tissue. Gives general protection against external injuries. Inner and outer bark are separated by a bark cambium. D, Sapwood, which contains both living amd dead tissues, is the light-colored wood beneath the bark. Carries sap from roots to leaves. E, Heartwood Iinactive is formed by a gradual change in the sapwood. F, Pith is the soft tissue about which the first wood growth takes place in the newly formed twigs. G, Wood rays connect the various layers from pith to bark for storage and transfer of food.

Bark, Wood and Pith[edit | edit source]

A cross section of a tree shows the following well-defined features in succession from the outside to the center: (1) Bark, which may be divided into the outer, corky, dead part that varies greatly in thickness with different species and with age of trees, and the thin, inner living part; (2) wood, which in merchantable trees of most species is clearly differentiated into sapwood and heartwood; (3) the pith, indicated by a small central core, often darker in color, which represents primary growth formed when woody stems or branches elongate.

Most branches originate at the pith, and their bases are intergrown with the wood of the trunk as long as they are alive. These living branch bases constitute intergrown knots. After the branches die, their bases continue to be surrounded by the wood of the growing trunk. Such enclosed portions of dead branches constitute the loose or encased knots. After the dead branches drop off, the dead stubs become overgrown and, subsequently, clear wood is formed. In a tree, the part containing intergrown knots comprises a cylinder, extending the entire length of the tree; the part containing loose knots forms a hollow cylinder, extending from the ground to the base of the green crown. Clear wood constitutes an outer cylinder covering overgrown branch ends. In second-growth trees, the clear zone and even the zone of loose knots may be absent.

Growth Rings[edit | edit source]

Between the bark and the wood is a layer of thin-walled living cells called the cambium, invisible without a microscope, in which most growth in thickness of bark and wood arises by cell division. No growth in either diameter or length takes place in wood already formed; new growth is purely the addition of new cells, not the further development of old ones. New wood cells are formed on the inside and new bark cells on the out- side of the cambium. As the diameter of the woody trunk increases, the bark is pushed out- ward, and the outer bark layers become stretched, cracked, and ridged in patterns often characteristic of a species. A bark cambium

forms from living cells and this tissue separates the outer bark from the inner bark.

With most species in temperate climates, there is sufficient difference between the wood formed early and that formed late in a growing season to produce well-marked annual growth rings. The age of a tree at the stump or the age at any cross section of the trunk may be determined by counting these rings (fig. 2-2). If the growth of trees in diameter is interrupted by drought or defoliation by insects, more than one ring may be formed in the same sea- son. In such an event, the inner rings usually do not have sharply defined boundaries and are termed false rings. Trees that have only very small crowns or that have accident- ally lost most of their foliage may form only an incomplete growth layer, sometimes called a discontinuous ring, until the crown is restored.

Growth rings are most readily seen in species with sharp contrast between earlywood and latewood, such as the native ring-porous hardwoods as ash and oak, and most softwoods except in soft pines. In some other species, such as water tupelo, sweetgum, and soft maple, differentiation of early and late growth is slight, and the annual growth rings are difficult to recognize. In some tropical regions, growth may be practically continuous throughout the year, and no well-defined annual rings are formed.

Earlywood and Latewood[edit | edit source]

The inner part of the growth ring formed first in the growing season is called earlywood or springwood, and the outer part formed later in the growing season, latewood or summerwood. Actual time of formation of these two parts of a ring may vary with environmental and weather conditions. Earlywood is characterized by cells having relatively large cavities and thin walls. Latewood cells have smaller cavities and thicker walls. The transition from earlywood to latewood may be gradual or abrupt, depending on the kind of wood and the growing conditions at the time it was formed. In some species, such as the maples, gums, and yellow-poplar, there is little differ- ence in the appearance of the earlywood and latewood parts of a growth ring.

When growth rings are prominent, as in most softwoods and the ring-porous hard- woods, earlywood differs markedly from latewood in physical properties. Earlywood is lighter in weight, softer, and weaker than latewood; it shrinks less across and more lengthwise along the grain of the wood. Because of the greater density of latewood, the proportion of late- wood is sometimes used to judge the quality or strength of wood. This method is useful with such species as the southern pines. Dougias-fir, and the ring-porous hardwoods - ash, hickory, and oak.

Sapwood and Heartwood[edit | edit source]

Sapwood is located next to the cambium. It contains only a few living cells and functions primarily in the storage of food and the mechanical transport of sap. The sapwood layer may vary in thickness and in the number of growth rings contained in it. Sapwood commonly ranges from 11.5 to 2 inches in radial thickness. In certain species, such as catalpa and black locust, the sapwood contains very few growth rings and sometimes does not exceed one-half inch in thickness. The maples, hickories, ashes, some of the southern pines, and ponderosa pine may have sapwood 3 to 6 inches or more in thickness, especially in second-growth trees. As a rule, the more vigorously growing trees of a species have wider sapwood layers. Many second-growth trees of merchantable size consist mostly of sapwood.

Heartwood consists of inactive cells that have been slightly changed, both chemically and physically, from the cells of the inner sap- wood rings. In this condition these cells cease to conduct sap.

The cell cavities of heartwood also may contain deposits of various materials which frequently give much darker color to the heart- wood. All heartwood, however, is not dark colored. Species in which heartwood does not darken to a great extent include the spruces (except Sitka spruce), hemlock, the true firs, Port-Orford-cedar, basswood, cottonwood, and buckeye. The infiltrations or materials deposited in the cells of heartwood usually make the wood more durable when used in exposed situations. Unless treated, all sapwood is non- durable when exposed to conditions that favor decay.

In some species, such as the ashes, hickories, and certain oaks, the pores become plugged to a greater or lesser degree with ingrowths, known as tyloses, before the change to heartwood is completed. Heartwood having pores tightly plugged by tyloses, as in white oak, is suitable for tight cooperage.

Heartwood has a higher extractives content than sapwood, and because of this, exhibits a higher specific gravity. For most species the difference is so small as to be quite unimportant. The weight and strength of wood are influenced more by growth conditions of the trees at the time the wood is formed than they are by the change from sapwood to heartwood. In some instances, as in redwood, western red cedar, and black locust, considerable amounts of infiltrated material may somewhat increase the weight of the wood and its resistance to crushing.

Wood Cells[edit | edit source]

Wood cells that make up the structural elements of wood are of various sizes and shapes and are quite firmly grown together. Dry wood cells may be empty or partly filled with deposits, such as gums and resins, or with tyloses. A majority of cells are considerably elongated and pointed at the ends: they are customarily called fibers or tracheids. The length of wood fibers is highly variable within a tree and among species. Hardwood fibers average about one twenty-fifth of an inch in length (1 mm.); softwood fibers (called tracheids) range from one-eighth to one-third of an inch in length (3 to 8 mm.).

In addition to their fibers, hardwoods have cells of relatively large diameter known as vessels. These form the main arteries in the movement of sap. Softwoods do not contain special vessels for conducting sap longitudinally in the tree; this function is performed by the tracheids.

Both hardwoods and softwoods have cells (usually grouped into structures) that are oriented horizontally in the direction from the pith toward the bark. These structures conduct sap radially across the grain and are called rays or wood rays. The rays are most easily seen on quartersawed surfaces. They vary greatly in size in different species. In oaks and sycamores, the rays are conspicuous and add to the decorative features of the wood.

Wood also has other cells, known as longitudinal, or axial, parenchyma cells, that function mainly for the storage of food.

Chemical Composition of Wood[edit | edit source]

Dry wood is made up chiefly of the following substances, listed in decreasing order of amounts present: Cellulose, lignin, hemicelluloses, extractives, and ash-forming minerals.

Cellulose, the major constituent, comprises approximately 50 percent of wood substance by weight. It is a high-molecular weight linear polymer that, on chemical degradation by mineral acids, yields the simple sugar glucose as the sole product. During growth of the tree, the linear cellulose molecules are arranged into highly ordered strands called fibrils, which in turn are organized into the larger structural elements comprising the cell wall of wood fibers. The intimate physical, and perhaps partially chemical, association of cellulose with lignin and the hemicelluloses imparts to wood its useful physical properties. Delignified wood fibers have great commercial value when re- constituted into paper. Moreover, they may be chemically altered to form synthetic textiles, films, lacquers, and explosives.

Lignin comprises 23 to 33 percent of soft-woods, but only 16 to 25 percent of hardwoods. It occurs in the wood largely as an intercellular material. Like cellulose, it has a macromoleculal chemical structure, but its three-dimensional network is far more complex and not yet completely worked out. As a chemical, lignin is an intractable, insoluble material, probably bonded at least loosely to the cellulose. To remove it from the wood on a commercial scale requires vigorous reagents, high temperatures, and high pressures. Such conditions greatly modify the lignin molecule, producing a complex mixture of high-molecular- weight phenolic compounds.

To the paper industry, lignin is difficult to solubilize and is a sometimes troublesome by- product. Theoretically, it might be converted to a variety of chemical products but, practically, a large percentage of the lignin removed from wood during pulping operations is burned for heat and recovery of pulping chemicals. One sizable commercial use for lignin is in the formulation of drilling muds, used in the drilling of oil wells, where its dispersant and metal- combining properties are valuable. It has found use also in rubber compounding and as an air-entraining agent in concrete mixes. Lesser amounts are processed to yield vanillin for flavoring purposes and to product solvents such as dimethyl sulfide and dimethyl sulfoxide.

The hemicelluloses are intimately associated with cellulose in nature and, like cellulose, are polymeric units built up from simple sugar molecules. Unlike cellulose, however, the hemi- celluloses yield more than one type of sugar on acid cleavage. Also, the relative amounts of these sugars vary markedly with species. Hard- woods contain an average of 20 to 30 percent hemicelluloses with xylose as the major sugar. Lesser amounts of arabinose, mannose, and a sugar acid are also attached to the main polymer chain. Softwoods contain an average of 15 to 20 percent hemicelluloses, with mannose as the main sugar unit. Xylose, arabinose, and the sugar acid are again present at lower levels. The hemicelluloses play an important role in fiber-to-fiber bonding in the papermaking process. The component sugars of hemicellulose are of potential interest for conversion into chemical products.

Unlike the major constituents just discussed, the extractives are not part of the wood structure. However, they do contribute to such properties of wood as color, odor, taste, decay resistance, strength, density, hygroscopicity, and flammability. They include tannins and other poly-phenolics, coloring matters, essential oils, fats, resins, waxes, gums, starch, and simple metabolic intermediates. They can be removed from wood by extraction with such inert neutral solvents as water, alcohol, acetone, benzene, and ether. In quantity, the extractives may range from roughly 5 to 30 percent, depending on such factors as species, growth conditions, and time of year the tree is cut.

Ash-forming minerals comprise from 0.1 to 3 percent of wood substance, although considerably higher values are occasionally reported. Calcium, potassium, phosphate, and silica are common constituents. Due to the uniform distribution of these inorganic materials throughout the wood, ash often retains the micro-structural pattern of wood.

A significant dollar value of nonfibrous products is produced from wood including naval stores, pulp byproducts, vanillin, ethyl alcohol, charcoal, extractives, and bark products.

Identification[edit | edit source]

Many species of wood have unique physical, mechanical, or chemical properties. Efficient utilization dictates that species should be matched to use requirements through an understanding of properties. This requires identification of the species in wood form, independent of bark, foliage, and other characteristics of the tree. Field identification can often be made on the basis of readily visible characteristics such as color, presence of pitch, or grain pattern. Sometimes odor, density, or splitting tendency is helpful. Where more positive identification is required, a laboratory investigation of the microscopic anatomy of the wood can be made. Detailed descriptions of identifying character- istics are given in texts such as "Textbook of Wood Technology" by Panshin and de Zeeuw.

Bibliography[edit | edit source]

Bratt, L. C. 1965. Trends in the production of silvichemicals in the United States and abroad. Tappi 48(T) : 46A-49A. Tech. Assoc. Pulp and Paper Indus.

Brauns, F. E., and Brauns, D. A. 1360. The chemistry of lignin-supplement volume, 804 pp. Academic Press.

Browning, B. L. 1963. The chemistry of wood. 689 pp. Interscience Publishers, N.Y.

Freudenberg, K. 1965. Lignin: Its constitution and formazcy from p-hydroxy-cinnamyl alcohols. Sci. 148: 595-600.

Hamilton, J. K., and Thompson, N. S. 1959. A comparison of the carbohydrates of hardwoods and softwoods. Tappi 42: 752-760. Tech. Assoc. Pulp and Paper Indus.

Ott, E., Spurlin, H. M., and Grafflin, M. W. 1954. Cellulose and cellulose derivatives. Volume

V. Parts I, II, and III (1966) of High Polymers. 1601 pp. Interscience Publishers, N.Y.

Panshin, A. J., and de Zeeuw, C. 1970. Textbook of wood technology. Volume 1. 3d edition. McGraw-Hill.

Wise, L. E., and Jahn, E. C. 1952. Wood chemistry. Volumes I and II, 1259 pp. Reinhold.

Further Reading[edit | edit source]

Content currently available at Hathi Trust Digital Library and here.

Bibliographic Information[edit | edit source]

Collected by: Forest Products Laboratory (U.S.), 1974, "Wood Handbook: Wood as an Engineering Material", Forest Products Laboratory, USDA.

Chapter 2: Structure of Wood of the "Wood Handbook: Wood as an Engineering Material" was ported by Chris Ruest and Steven Vickers.

Copyright Information[edit | edit source]

Public Domain.