Current market options used to pass a fibre from a vacuum environment to an ambient pressure environment use a complex, hermetically sealed, tube that houses a segment of fibre that passes through the vacuum interface. Whilst effective, these designs are expensive with high leadtimes, as they require precisely machined parts, and lack flexibility as an entirely new device needs to be manufactured if the fibre type needs to be changed.

Here we outline the fabrication of a simple, and cheap, vacuum feedthrough that is compatible with every fibre optic type. Our system has the additionally advantage that, changing the fibre type, length, structure or any other design consideration is simple and quick and does not require re-manufacturing of the feedthrough system.

Understanding the market[edit | edit source]

Current market options are based on a hermetically sealed fibre housing.[1] Whilst effective, their complex design inhibits flexibility and customisability for the user, whilst keeping costs and lead-times high.

Design[edit | edit source]

Conceptually, our design consists of an M10 bolt that passes through a standard CF vacuum flange (such as the one attached below).

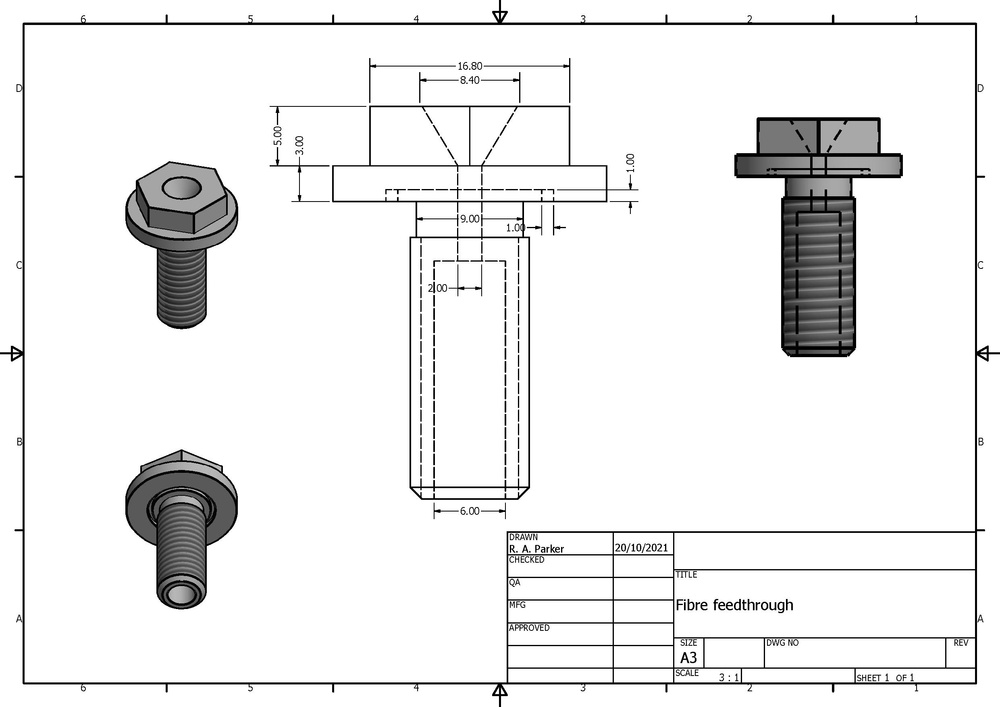

This vacuum flange then has a modified M10 bolt placed through it that has a countersunk central hole that accommodates the fibre. A conceptual image of the bolt is shown below:

The exact design specifications can be found in the design specifications below.

Finally, a fibre optic is placed through the central hole an a non-outgassing expoxy is used to fill the countersunk taper on the bolt. LOCTITE ABLESTIK 285 is one such adhesive expoy.

Once the epoxy is in place, an O-ring needs to be placed in the 1mm grove on the underside of the bolt-head, to allow for vacuum sealing. Then all that remains is for the bolt to be inserted through the vacuum flange with the bolt located in the ambient pressure environment, tightened to compress the O-ring using a nut on the backside of the flange.

References[edit | edit source]

Contact details[edit | edit source]

If required, these feedthroughs can be made for you by contacting[edit | edit source]

Ryan Parker and Jesus Arjona-Martinez; Room 865, the Rutherford Building - Cavendish Laboratories, JJ Thomson Ave, Cambridge CB3 0HE.

e-mail: rap71@cam.ac.uk and ja618@cam.ac.uk