Introduction[edit | edit source]

As the effects of climate change become progressively visible, there is a greater call to shift towards regionally sustainable practices. Such practices would ideally be capable of being maintained indefinitely, and can be supported solely from within the region. Renewable energy has the potential to not only reduce emissions contributing to climate change, but to move toward regional sustainability and increase resilience in dealing with the effects of climate change. Methods for reducing emissions of greenhouse gases while still providing power to meet the population’s needs are increasingly critical. This has created demand for power production that satisfies our growing population, but is independent of fossil fuels. Local availability of energy resources will determine which renewable energy paths are feasible for a given region. In Northern California, the abundance of timber makes biomass a logical renewable option.

“California, with 26 operating biomass power facilities, leads the nation in biomass power supplied to the electrical grid, but only one of those plants has been built in the last 15 years,” (Carlson, 2008). Carlson cites a combination of high wood fuel costs and moderate utility avoided costs as the reasons for the lack of newly constructed facilities. There was formerly a fifteen mega-watt biomass facility on the Georgia-Pacific sawmill site that closed when the sawmill shut down. One of the driving forces behind determining the feasibility of a project like this is the substantial amount of unused wood waste from forest management and milling activities. Concern for fire safety of adjoining overstocked timber communities is another cause for investigation of the feasibility of biomass as an alternative energy source for Mendocino County.

Primarily we compare two major existing case studies: a report on creating secure, renewable energy in Humboldt County by the Schatz Energy Research Lab at Cal Poly Humboldt and a UC Davis case study on the feasibility of Biomass in Mendocino County. With the cost of energy rising since the date of these studies, we are going to re-evaluate if Mendocino County would be an appropriate site for the production of fossil fuel alternatives from biomass, and how this project would impact the local economy. Mendocino is similar to Humboldt in many ways, making it the ideal candidate for this project. Table 1 (see Mendocino County Background) shows the comparison between Humboldt and Mendocino counties. They are comparable in land area and density of persons per square mile (from the 2010 U.S. Census), with populations both on the coast and further inland. Mendocino County has an abundance of timber, and accompanying industry, providing for a large amount of left over tree material for the production of bio-fuel.

Questions[edit | edit source]

Throughout the course of our analysis for this project, there are a variety of research questions we would like to address. First, we will examine the environmental, social and private benefits and costs associated with this project. Then, we will determine if it is feasible to establish a biomass plant in Mendocino County. If not, can we offer suggestions to make the costs weigh less than the total benefits? Furthermore, what mitigation measures could be used to make this plant the best alternative energy option for Mendocino County? We plan to evaluate which economic and energy efficiency policy recommendations could be made to this project to make it a feasible and profitable investment. Lastly, can the heat from the boiler be used for co-generation? We plan to answer all of these questions by the conclusion of this research paper.

Objectives[edit | edit source]

We have several objectives for this economic energy analysis. First we will determine the feasibility of a biomass energy production plant in Mendocino County by examining the environmental, social, and private benefits and costs. Next, we plan to evaluate the mitigation measures that will decrease the costs of the establishment a biomass plant in Mendocino County. We will also make recommendations to increase economic gains and or energy efficiency for the biomass plant. This will include suggesting additional mitigation measures to make the project more viable such as co-generation. A biomass plant with co-generation would allow other local businesses to utilize the steam produced from the facility.

Methods[edit | edit source]

In order to complete our objectives for this project and answer our outlined research questions, our team will perform a cost benefit analysis of a biomass plant. We researched existing biomass power plants in Humboldt County; making note of costs, capacity, and supply. Due to similarities in population size and environmental ecology, we chose to do our project in Mendocino County. To get a localized and knowledgeable perspective, we contacted professionals and experts involved in the field in Mendocino County to get their input on the biomass project. Then, we will extrapolate research from the Fort Bragg Biomass Power Facility Feasibility Analysis, the Schatz Energy Resource Center Energy Report, National Renewable Energy Lab and the United States Census Bureau. We will utilize this information to create a cost benefit analysis spreadsheet. Finally, with the spreadsheet and compilation of information we will determine the economic feasibility of a biomass plant in Mendocino County. Mendocino County Background Mendocino County is large in land size but small on people. Table 1 shows a selection of the U.S. Census Bureau’s statistics on Humboldt and Mendocino counties for 2010. Mendocino County is a collection of small, tourist-dependent coastal villages, suburban developments in two larger cities inland, and many tiny towns. Mendocino also has a long tradition in the logging and fishing industries, although it is on a much smaller scale presently.

Mendocino County Background[edit | edit source]

Mendocino County is large in land size but small on people. Table 1 shows a selection of the U.S. Census Bureau’s statistics on Humboldt and Mendocino counties for 2010. Mendocino County is a collection of small, tourist-dependent coastal villages, suburban developments in two larger cities inland, and many tiny towns. Mendocino also has a long tradition in the logging and fishing industries, although it is on a much smaller scale presently.

Table 1: A comparison between Humboldt and Mendocino counties relative to California

| Category | Humboldt County | Mendocino County | California (point of reference) |

|---|---|---|---|

| Population | 134,623 | 87,841 | 37,253,956 |

| Land Area in Square Miles | 3,567.99 | 3,506.34 | 155,779.22 |

| Persons per Square Mile | 37.7 | 25.1 | 239.1 |

| Median Household Income | $35,985 | $41,488 | $58,925 |

Statistics taken from U.S. Census Bureau County Quick Facts 2010

Plant Location[edit | edit source]

In the Fort Bragg Biomass Power Facility Feasibility Analysis, the Carlson Small Power Consultants determined criteria making the Georgia Pacific bark dump in south Fort Bragg an ideal site. The site is remote enough that it should cause issues with neighbors due to noise or traffic. The bark dump already has an industrial use background (redwood bark disposal) so that major use changes are not required. Parts of the site are located within quarter mile of PG&E’s main transmission line serving the Ft. Bragg area and the 60KV line has sufficient capacity to accept the proposed project. The location can be served by a quarter mile extension of Summers Lane from Highway 20. The bark dump contains a substantial quantity of buried redwood bark, which may be able to supplement existing fuel sources. Ash from the wood combustion can be used to replace the redwood bark reclaimed from the project site, representing an economic disposal option as well as a net positive environmental benefit to the site. The grounds are large enough to accommodate the fuel storage required due to the seasonal availability of a large fraction of the total fuel supply. The location is adjacent to the proposed regional park and golf course (to the south) that has undergone extensive aquifer testing and groundwater modeling to determine groundwater availability for the proposed development with positive results. The adjacent park and golf course has a need for 250 – 300 gpm of water for irrigation purposes, water that will be stored in two on site lakes. Approximately 50 gpm of irrigation water could be supplied by the power plant to the lakes (Carlson, 2008.).

Project Description & Design[edit | edit source]

Biomass Plant System Elements[edit | edit source]

This plant will utilize the available timber fuel in Mendocino County to create a sustainable source of energy. Initially, localized forest biomass fuel will be transported to the plant on trucks. The waste will then be burned in furnaces at the plant, where the heat created is used to boil water. The steam from the water then rotates turbines to generate energy.

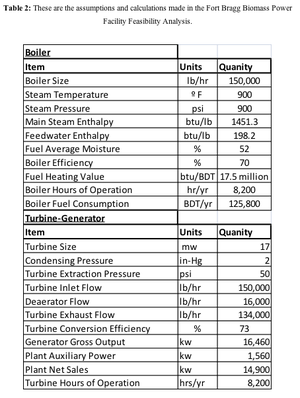

In order to make this plant feasible and sustainable, a plant size must be chosen that will optimize fuel supply without depleting or taxing the resource. A biomass fuel analysis determined that approximately 128,000 BDT/yr was available for use. Therefore, a reasonable facility size would contain a 150,000 lb/hr boiler, consuming 125,800 per bone dry ton (BDT) of fuel during an 8,200 hour year operating with a continuous load (Carlson, 2008). Assumptions for these findings are from the illustrated in Fort Bragg Biomass Power Facility Feasibility Analysis located in Table 2. The electricity produced from the steam for a boiler of this size would produce a total output of 16,460 KW. Furthermore, 9.5% of the power will be used within the biomass facility and an additional 14,900 KW will be sold to the grid (Carlson, 2008).

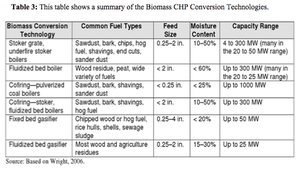

The common conversion technologies for biomass plants include gasification and direct-fired systems. Although gasification technologies are considered to be more efficient, they are confined to smaller plants and have additional limitations regarding feed sizes and moisture content (Naik-Dhungel, 2007). The various biomass plant technologies and qualifications are illustrated in Table 3.

This biomass plant will use a direct-fired boiler design that has been determined to be efficient and familiar to local California engineers and operators. This standard design is called a spreader stoker fed movable grate. This system will be appropriate as it accommodates the necessary fuel types with a relatively large feed size and high moisture content. A spreader stoker fed movable grate utilizes the traveling, shaking and rotating technique while a fluidized bed uses bubbling and circulating. Although a fluidized bed boiler was considered, it was concluded unnecessary as the fuel is expected to be rather homogeneous and it would have higher initial costs and power requirements (Carlson, 2008).

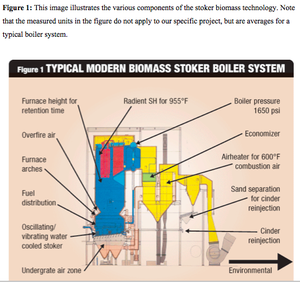

Energy Environmental Analysis Inc. states that most “modern mechanical stokers consist of four elements, 1) a fuel admission system, 2) a stationary or moving grate assembly that supports the burning fuel and provides a pathway for the primary combustion air, 3) an overfire air system that supplies additional air to complete combustion and minimize atmospheric emissions, and 4) an ash discharge system” (Naik-Dhungel, 2007). The various elements of the stoker are illustrated in Figure 1. Because this facility will utilize the spreader stoker fed movable grate technology, it incorporates a device that distributes fuel evenly over the grate by thrusting fuel particulate into the air. By distributing fuel to an even depth on the grate and allowing the grate to shake and travel, this type of stoker is extremely efficient.

It was determined that the steam selected for this plant will be at 900 psi and 900º F. These levels provide reasonable efficiency and are proven reliable as they are commonly found in most California biomass facilities. The steam turbine-generator has 3,600 rpm with voltage ranging from 13.8 kv to 12.47kv. A two cell mechanical draft cooling tower will exist to cool the plant circulating water and the water will be supplied by on site or Park District wells at approximately 240 gpm (Carlson, 2008). In addition, the boiler contains an electrostatic precipitator to control exiting particulate matter. Since forestry operations are limited by season in Northern California, the plant will also include a large fuel storage area that can hold up to 40,000 BDT of fuel.

Technical Reliability[edit | edit source]

To operate an efficient and profitable biomass power plant, systems must be designed to flexibly accommodate variability in available raw materials and energy requirements for plant operations. More sustainable sources of biofuel and efficient conversion processes, as well as more flexible control technologies, together offer the potential to offset growing energy demands on a carbon-neutral basis (GE Intelligent Platforms, 2011). Reliability and maximum up-time is the key to success in this operation. According to industry experts with impressive long track records of success in this field, these are the determining factors for a successful bio-power operating facility (Neville, 2010).

Fuel[edit | edit source]

This fuel plan has attempted to be conservative in its approach to accumulate a critical mass of annual fuel. Sources of feedstock identified for this project are Mill Waste, Forest Residuals, Urban Wood Waste, Log Yard Cleanup, and Fire Protection Thinning, with minor contributions of material from commercial tree trimming, right-of-way clearing, and clearing for construction and agricultural activities. The plan is designed to allow fueling of the facility even during downturns in the forest products industry, as is currently being experienced. The amount of material is sufficient to fuel a 15 MW biomass power facility on a year round full load basis. Because of the seasonality of forest operations on the north coast, the plant will feature a large fuel storage area capable of holding up to 40,000 BDT of fuel. The structure of the likely power contract for this facility will allow plant curtailments during off peak periods as a fuel saving measure with almost no loss in margin (Carlson, 2008).

Process Equipment, Control, and Automation[edit | edit source]

We chose thermal technologies as the basis of process equipment selection for this project because they are the least sensitive to the qualities of the feedstock, and are able to effectively process other natural, abundant and renewable resource such as lignocellulosic materials. These technologies are inherently the most scalable and do not require material exclusively grown for this operation. Critical path transfer components must be selected and maintained with care to avoid failures that can shut down the whole line. This proposal defines the activities associated with the supply and installation of a 150,000 PPH wood-fired steam generation system, and a nominally rated 17,000 KW electrical generating facility utilizing a condensing-extraction steam turbine-generator unit (Neville, 2010). Wellons’ proposed scope includes equipment supply, foundation design, permitting support, mechanical installation services, commissioning and start-up services, operator training, and other support services necessary to result in a complete and operating system. The design is proven and is familiar to many operators in California. Because the fuel is expected to be fairly uniform in origin (redwood and Douglas fir wood and bark), and Ft. Bragg is in attainment for air quality criteria pollutants, the higher capital cost and auxiliary power requirements of a fluidized bed could not be justified for this project. Incorporated in this assessment is a comprehensive operations and maintenance (O&M) budget to ensure maximum plant up time (Carlson, 2008). Flexible control technology solutions play a key role in helping producers address the variability of biomass feed-stocks and the issues associated with real-time control for combustion, feed water, blow down, and burner management. Automation systems that support advanced process control strategies while also providing easy configuration, openness, and connectivity can help producers optimize every step of their process and position them to capitalize on the potential opportunities of biomass power generation—resulting in increased operational efficiency, lower total cost of ownership, and environmental sustainability. Both process control and automation are key features of the proposed plant (GE Intelligent Platforms, 2011).

Installed System Monetary Costs[edit | edit source]

Once the system is in place and all the costs of installation and set up are complete, there are ongoing costs to run the system. The most important cost will be the fuel, which includes harvest and transportation of the fuel source before it reaches the plant. The price for woody fuel can range from around 20 dollars per BDT to 60 dollar per BDT as shown in Table 4. This depends on the source of the wood or other fuel, whether it is from a private company, whether it is left over byproduct, and the species of wood, as well as transportation used and the distance over which it needs to be transported. Other biomass plants use the residual ash as a product, which is then distributed to local farmers to maintain healthy fields. Facilities maintenance costs are another ongoing cost. Running and maintaining equipment like turbines and boilers, as well as machinery like front end and skid loaders. There are also the costs of natural gas or other electricity to start the power generation process. Labor costs will depend upon the size of the plant. A 15 MW or more plant is best, since there is little increase in labor cost compared to a 10MW plant. According to the Fort Bragg Biomass Power Facility Feasibility Analysis, the costs for biomass electricity generation depend on fuel, capital and non-fuel maintenance and operating expenses. Carlson states that the “levelized cost of electricity (COE) from a new biomass power plant generating only electricity for sale lies in the range of $0.06 to 0.08/kWh for installed capital costs of $1500 to 3000/kW” (Carlson, 2008). This estimate has anticipated a relatively low base fuel cost of $20/BDT and includes revenue return. In addition, the analysis makes the assumptions that the project will have “20% net efficiency, 5% interest on debt, 85% capacity factor, no capacity payments, 20 year economic life, straight line depreciation and 2.1% annual escalation in operating and maintenance costs but no escalation in fuel cost” (Carlson, 2008). At this point in time, average biomass fuel cost has ranged between $22/BDT and $40/BDT since 1986. It is assumed that the high of $40/BDT may have the potential to increase COE to $0.10/kWh (Carlson, 2008). The DG Fairhaven biomass plant is an existing plant in a similar location in Samoa, CA in Humboldt County. The plant size is 18.75MW. The majority of their fuel source comes from logs that are not usable as lumber, and also sawdust from local sawmills. Depending on the moisture content the plant can produce 1MW of power for every 1.86 to 2 tons of fuel. From PG&E the plant receives 42 dollars per MW, or 4.2 cents per kWh.

References[edit | edit source]

Baker, T. (2010, December 15). Renewable energy: Biomass crop assistance program. Retrieved from http://web.archive.org/web/20110213080308/http://www.bakertilly.com/Biomass-Crop-Assistance-Program.

Carlson, B. (2011, October 30). Email correspondence.

Carlson, B. (2008). Fort Bragg Biomass Power Facility Feasibility Analysis. Carlson Small Power Consultants, Redding, California. Retrieved October 1, 2011, from http://cemendocino.ucdavis.edu/files/17416.pdf.

Database of State Incentives for Renewables and Efficiency. (2011, October 14). Modified accelerated cost-recovery system (macrs) bonus depreciation (2008-2012). Retrieved from http://web.archive.org/web/20150223202457/http://dsireusa.org/incentives/incentive.cfm?Incentive_Code=US06F.

Engineering Toolbox. Internal Rate of Return. Retrieved November, 2011 from http://engineeringtoolbox.com/internal-rate-of-return-irr-d_1235.html.

GE Intelligent Platforms. (2011). Biomass boiler control solutions. Retrieved from http://www.ge-ip.com/industries/biomass/broiler_solutions.

International Energy Agency. (2010). Projected costs of generating electricity. Retrieved from http://www.google.com/search?client=safari&rls=en&q=investment rate of return for a coal fired power production plant&ie=UTF-8&oe=UTF-8.

Naik-Dhungel, N. (2007). Biomass Conversion Technologies. Energy and Environmental Analysis, Inc., Eastern Research Group, Inc. Retrieved October 10, 2011, from http://web.archive.org/web/20121129121140/http://www.epa.gov/chp/basic/catalog.html.

Neville, A. (2010, December 1) Top plant: Colmac Energy Inc.’s biomass- fueled power plant, mecca, California. Retrieved from http://www.powermag.com/renewables/waste_to_energy/Top-Plant-Colmac-Energy-Inc-s-Biomass-Fueled-Power-Plant-Mecca-California_3223_p2.html.

Mendocino County Woody Biomass Working Group. (2008). Biomass Feasibility in Mendocino County. University of California Cooperative Extension-Mendocino County. Retrieved October 18, 2011, from http://cemendocino.ucdavis.edu/Forestry/Biomass_Feasibility_in_Mendocino_County/.

U.S. Census Bureau. (2010). Humboldt County QuickFacts from the US Census Bureau. State and County QuickFacts. Retrieved October 18, 2011, from http://web.archive.org/web/20160224072029/http://quickfacts.census.gov:80/qfd/states/06/06023.html

U.S. Census Bureau. (2010). Mendocino County QuickFacts from the US Census Bureau. State and County QuickFacts. Retrieved October 18, 2011, from http://web.archive.org/web/20160219023722/http://quickfacts.census.gov:80/qfd/states/06/06045.html.

USDA, Farm Service Agency. (2011, September 20). Biomass crop assistance program for fsa. Retrieved from http://www.fsa.usda.gov/FSA/webapp?area=home&subject=ener&topic=bcap.

USDA, Farm Service Agency. (2008, August 20). About the commodity credit corporation. Retrieved from http://www.fsa.usda.gov/FSA/webapp?area=about&subject=landing&topic=sao-cc.

--Danielle Burkhart 21:39, 16 December 2011 (PST) Based on a Cost and Benefits Analysis by: Danielle Burkhart, Lawrence Chukweke, Megan Green, Seth Perez and Danielle Perrine