The straw is derived from renewable crops such as wheat grass and rice. Once threshed edible seeds of mature plants, strong and fibrous stalks that are left over are compacted into bales. The straw bales are renewable, durable, efficient and well insulated.[1]

How its used[edit | edit source]

- Rice slip construction is very similar to straw slip construction (also known as "light straw clay").

- The straw produced from the rice harvest is first dried. A frame of some sort is constructed, many times out of recycled wood, to create a holding container that becomes the wall. Create your mixture of clay-slip by filling a bucket with water and gradually adding clay while mixing. The clay-slip should be ready when you can dip your hand in, and it is covered evenly with the substance. Next, you may place your straw on a tarp and pour the clay-slip over it, and agitate so that all the straw is covered evenly. One can also dip the straw by the handful into the mixture. Place the coated straw into the wooden wall frame and pack down.

Properties and Characteristics[edit | edit source]

- Fresh, inexpensive and seismic

- It can be the size you want

- Rice straw: 0,5 mm average fiber length.

- The rice straw slip is thermally efficient and conserve energy, with R-values significantly better than conventional construction, depending on the type of straw and the thickness of the wall.[2]

Benefits[edit | edit source]

- The rice straw slip construction can provide benefits in areas where straw is a waste product. Nearly one million tons of rice straw are burned each fall in California, forming a curtain of smoke that lasts for weeks. The annual burning of straw in California produces more carbon monoxide that all power plants in the state.

- In contrast to the wood used to build, the straw can grow in less than a year in a fully sustainable production system.

- Straw can also be grown in saline soils or low quality. The potential for sustainability of any product will increase if the energy needed to manufacture them or manipulate them are kept to a minimum.

- Doesn't require expensive or complicated tools and those with expertise can be found all over the world.

- Combined with its high degree of insulation and ventilation, these walls create a feeling of comfort that isn't found in thin walls built with modern materials.

- Easy to learn for those new to natural building

- One of the beauties of this system is that everyone can participate in building a house, including women and children. The gathering of people to help build often generates great enthusiasm. Building walls in groups facilitates community-based projects that otherwise might not take place.[3]

History[edit | edit source]

- Humans have used grass or straw as a building material since the stone age.

- A straw slip house is convenient, cheap, efficient and resilient. Some straw structures built over 100 years ago still remain standing today.

Production in Dominican Republic[edit | edit source]

- The Dominican Republic has a strong rice cultivating industry. In 2010, Dominican Republic has achieved self-sufficiency in rice for the fifth consecutive year and also exported 346 600 quintals. For 2009, the country had a ready supply of 15,750,479 quintals of rice. Is also the first and only Central American and Caribbean country to be self-sufficient in rice production.[4]

- As of 2007 the consumption of rice within the Dominican Republic was estimated at 436,000 MT, with two main harvests, one in the Spring that accounts for 55-60% of production, and a smaller one in the fall that accounts for the remaining 35-40%[5]

- With production being consistent bi-annually, the rice straw needed for rice slip construction may be readily available at a local level.[verification needed]

Example[edit | edit source]

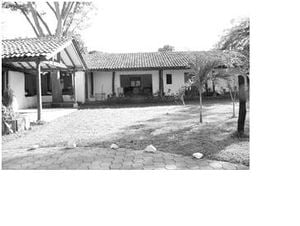

In Nicaragua a house was built with rice straw. Previously seen as waste, the straw became a construction material. In this example they first lined with straw bales and added in a mixture of cement and sand to fill them. It was built by the organization "Peace and Hope Trust".[6]

About Natural Building and Examples in Appropedia[edit | edit source]

References[edit | edit source]

- ↑ Citation added: DiSanto, Gilbert Translator: Cervantes Dueña, Juan Octavio. "Construyendo con paja" http://www.greenteacher.com/articles/construyendoconpaja.pdf>.

- ↑ Citation added: Swentzell,Athena; Steen,Bill; Bainbridge,David;Eisenber,David. "La Casa de Fardos de Paja" 1994. Web. 8 June 2011. http://imagopost.com/ecoaldeasmexico/DOWNLOADS/LaCasaDePaja_Steen.pdf>.

- ↑ Citation added: Swentzell,Athena; Steen,Bill; Bainbridge,David;Eisenber,David. "La Casa de Fardos de Paja" 1994. Web. 8 June 2011. http://imagopost.com/ecoaldeasmexico/DOWNLOADS/LaCasaDePaja_Steen.pdf>.

- ↑ Citation added: Graciano, Pamela. "Rep. Dominicana: Autosuficiente En Producción De Arroz." Mercados & Tendencias. 9 Mar. 2010. Web. 7 June 2011. http://www.revistamyt.com/comercio/782-rep-dominicana-autosuficiente-en-produccion-de-arroz>.

- ↑ Suarez, Carlos G. "Dominican Republic Grain and Feed Rice Production and Situation Update 2008." USDA Foreign Agricultural Service, Gain Report. US Government, 13 Nov. 2008. Web. 7 June 2011. http://www.fas.usda.gov/gainfiles/200811/146306414.pdf.

- ↑ Citation added: Brenes, Haydée. "Construyen casas con paja de arroz" El Nuevo Diario. 1 Feb. 2004. Web. 8 June 2011. http://web.archive.org/web/20120111131102/http://archivo.elnuevodiario.com.ni/2004/febrero/01-febrero-2004/nacional/nacional14.html>.